Mechanism and method for geotechnical engineering anti-failure reinforcement

A technology of geotechnical engineering and hoarding, which is applied in basic structure engineering, excavation, construction, etc., and can solve problems such as difficult construction and large impact on the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

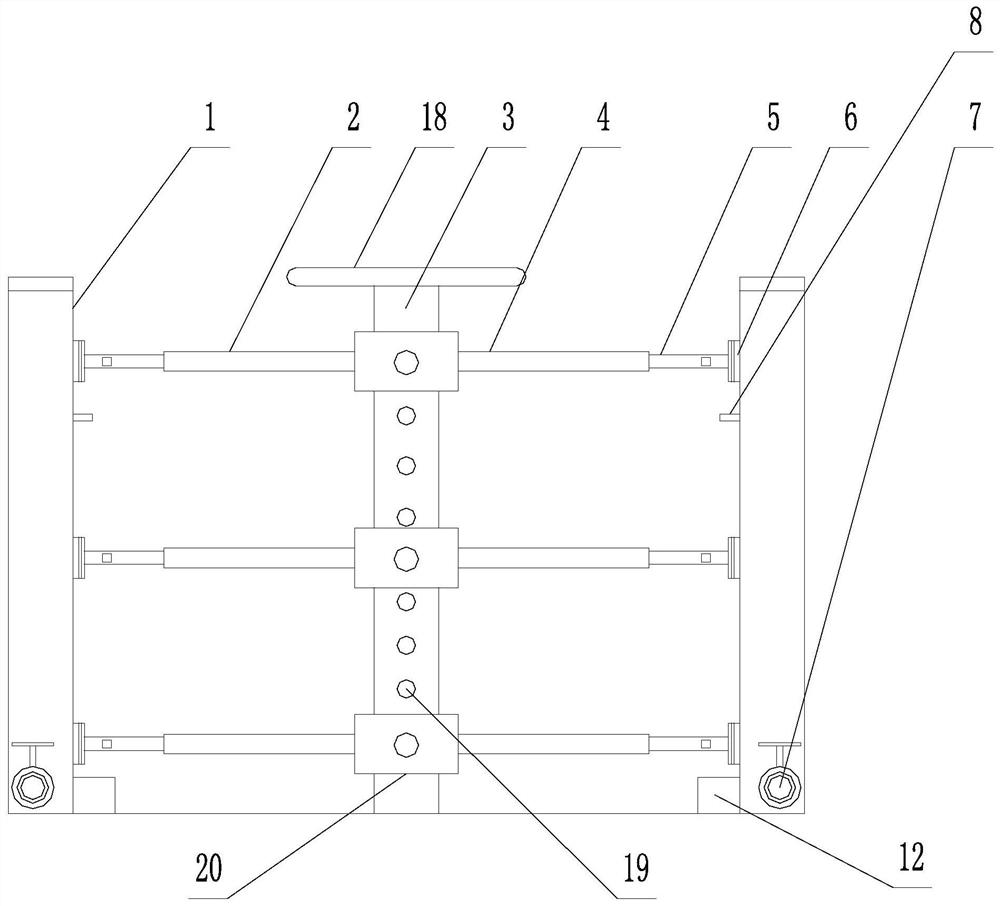

[0065] Such as figure 1 and figure 2 As shown, the mechanism for anti-destructive reinforcement of geotechnical engineering includes a foundation pit support assembly, and the foundation pit support assembly includes two shrouds 1, and also includes a support frame for supporting the shroud 1, and the two shrouds The plates 1 are distributed on a pair of opposite sides of the support frame;

[0066] The support frame includes a vertical rod 3 and a plurality of cross bars 2 arranged along the axial direction of the vertical rod 3, and the horizontal rod 2 is used as a support between the vertical rod 3 and the inner side of the coaming plate 1, and also includes a On the vertical pole 3, there are sleeves 20 that can slide along the axis of the vertical pole 3. Two crossbars 2 are fixed on each sleeve 20, and the crossbars 2 on each sleeve 20 are relative to the axis of the sleeve 20. line symmetric;

[0067] The length of the cross bar 2 is adjustable;

[0068] It also i...

Embodiment 2

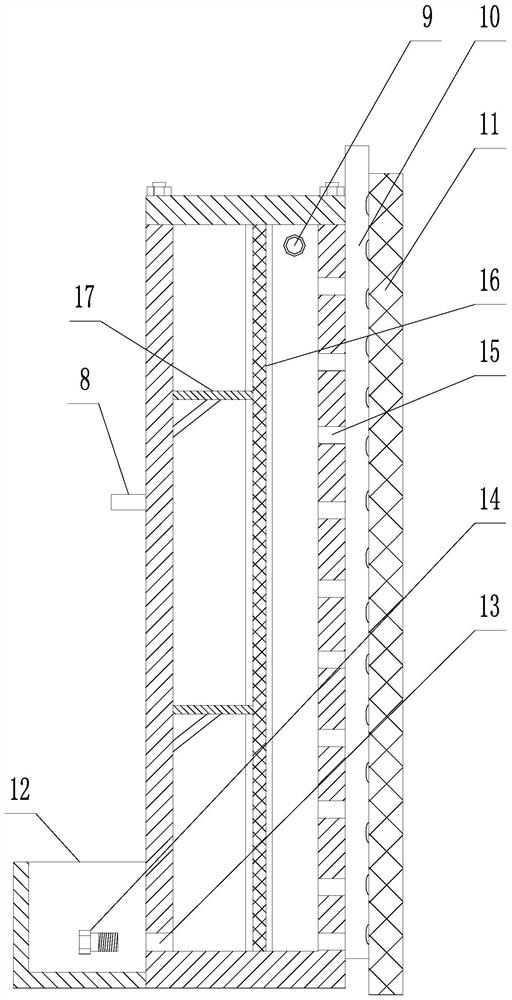

[0085] Such as figure 1 and figure 2 As shown, the present embodiment is further limited on the basis of embodiment 1:

[0086] The shroud 1 is a hollow plate structure;

[0087] The coaming plate 1 includes an outer plate for connecting with the foundation pit and an inner plate close to the center of the foundation pit, and the outer plate is provided with a plurality of communication holes 15 passing through the inner and outer sides of the outer plate;

[0088] The inner side plate is provided with a drain port 13 that runs through the inner and outer sides of the inner plate, and the fluid conduction capacity of the drain port 13 is adjustable;

[0089] It also includes a water tank 12 fixed on the inner board, and the outlet end of the drain port 13 is located in the water tank 12 . When this scheme is used in practice, the coaming 1 can be spliced by multiple plates. For example, according to the internal design, for the scheme that does not use the filter screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com