Electrochemically-driven artificial muscle fiber as well as preparation method and application thereof

An artificial muscle, electrochemical technology, applied in the field of material science, to achieve the effect of increasing specific surface area, improving energy density and driving stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The embodiment of the present invention also provides a preparation method of electrochemically driven artificial muscle fibers, which includes:

[0058] The carbon nanotube narrow band is prepared by a floating chemical vapor deposition method;

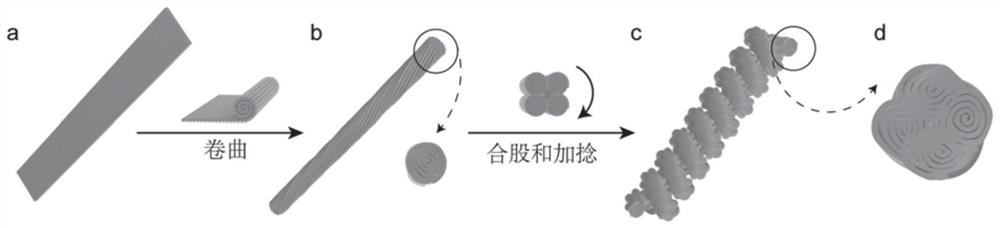

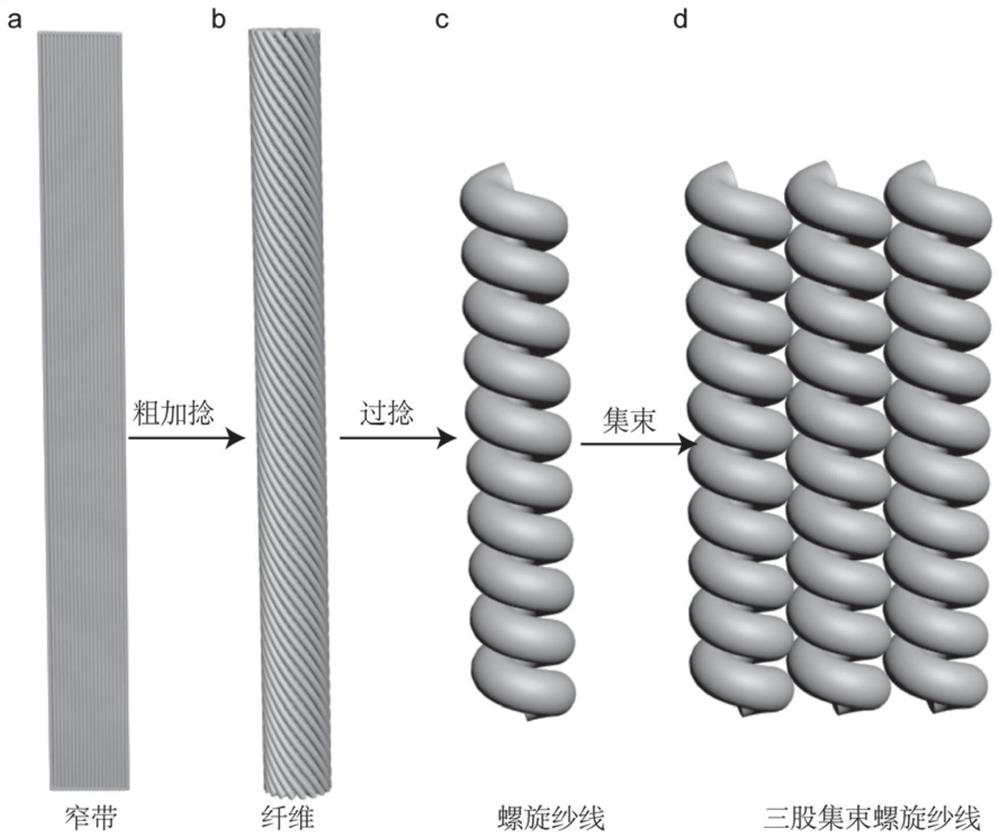

[0059] At least a plurality of carbon nanotube narrow strips are pre-crimped, plied, and twisted in sequence to form a uniform helical structure to form a muscle yarn, or at least the carbon nanotube narrow strips are twisted until a uniform helical structure is formed to obtain a muscle yarn The muscle yarn is the electrochemically driven artificial muscle fiber.

[0060] In some more specific embodiments, the preparation method includes: first coiling the narrow strip of carbon nanotubes along the length direction to form pre-crimped carbon nanotube fibers, and then performing multiple pre-crimped carbon nanotube fibers sequentially Muscle yarns are obtained by plying and twisting until a uniform helix is formed.

[0061...

Embodiment 1

[0076] see figure 1 , take a carbon nanotube narrow ribbon with a length of about 20 cm and a width of about 700 μm prepared by a floating catalytic method, and curl it along its length direction to form a pre-crimped carbon nanotube fiber with a diameter of 140 μm.

[0077] Take four identical pre-curled carbon nanotube fibers for plying, and then continue twisting (the twist is 2800 turns / m), until a uniform helical structure is formed, and then four pre-crimped carbon nanotube fibers are obtained. Artificial muscle yarn Threads, i.e. artificial muscle fibers, the length of which is about 6 cm and the diameter is about 125 μm;

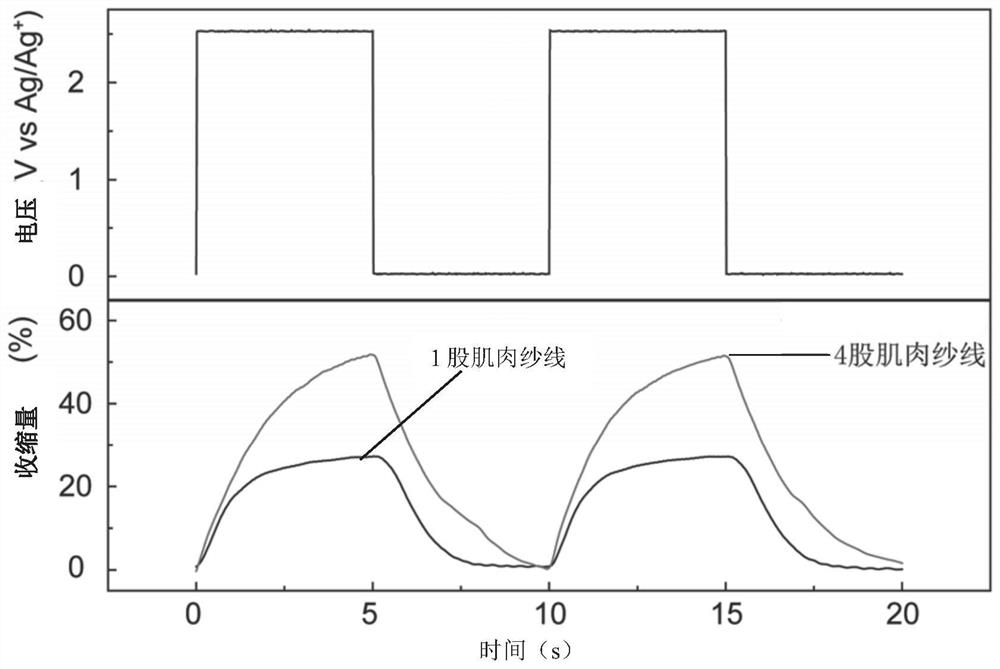

[0078] The artificial muscle fiber was used as the working electrode of the electrochemical drive system, activated with nitric acid (1M / L HNO 3 Adopt the CV method to activate the carbon nanotube film after 20 circles) as counter electrode, with Ag / Ag + The electrode was used as a reference electrode, and 0.2M tetraethylammonium tetrafluoroborate ...

Embodiment 2

[0087] see figure 1 , taking a carbon nanotube narrow strip with a length of about 20 cm and a width of about 700 μm prepared by a floating catalytic method, and curling it along its length direction to form a pre-crimped carbon nanotube fiber with a diameter of 140 μm;

[0088] Take four identical pre-curled carbon nanotube fibers and continue twisting (the twist is about 2800 turns / meter) until a uniform helical structure is formed, and then four pre-crimped carbon nanotube fibers are obtained. That is, artificial muscle fibers, the length of which is about 6cm and the diameter is about 125μm;

[0089] The artificial muscle fiber was used as the working electrode of the electrochemical drive system, activated with nitric acid (1M / L HNO 3 Adopt the CV method to activate the carbon nanotube film after 20 circles) as counter electrode, with Ag / Ag + The electrode was used as a reference electrode, and 0.2M tetraethylammonium tetrafluoroborate (TEA·BF 4 ) was dissolved in prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com