Template method manufacturing method of patterned electrostatic spinning fiber assembly

A fiber aggregate, electrospinning technology, applied in electrospinning, fiber processing, fiber chemical characteristics, etc., can solve the problems of difficult removal and inability to precisely control fiber deposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

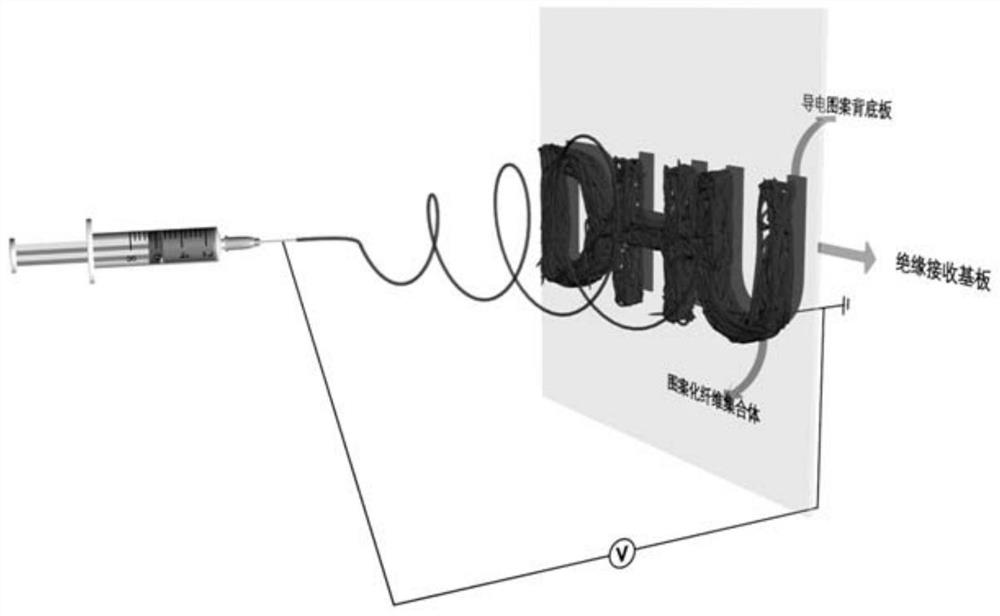

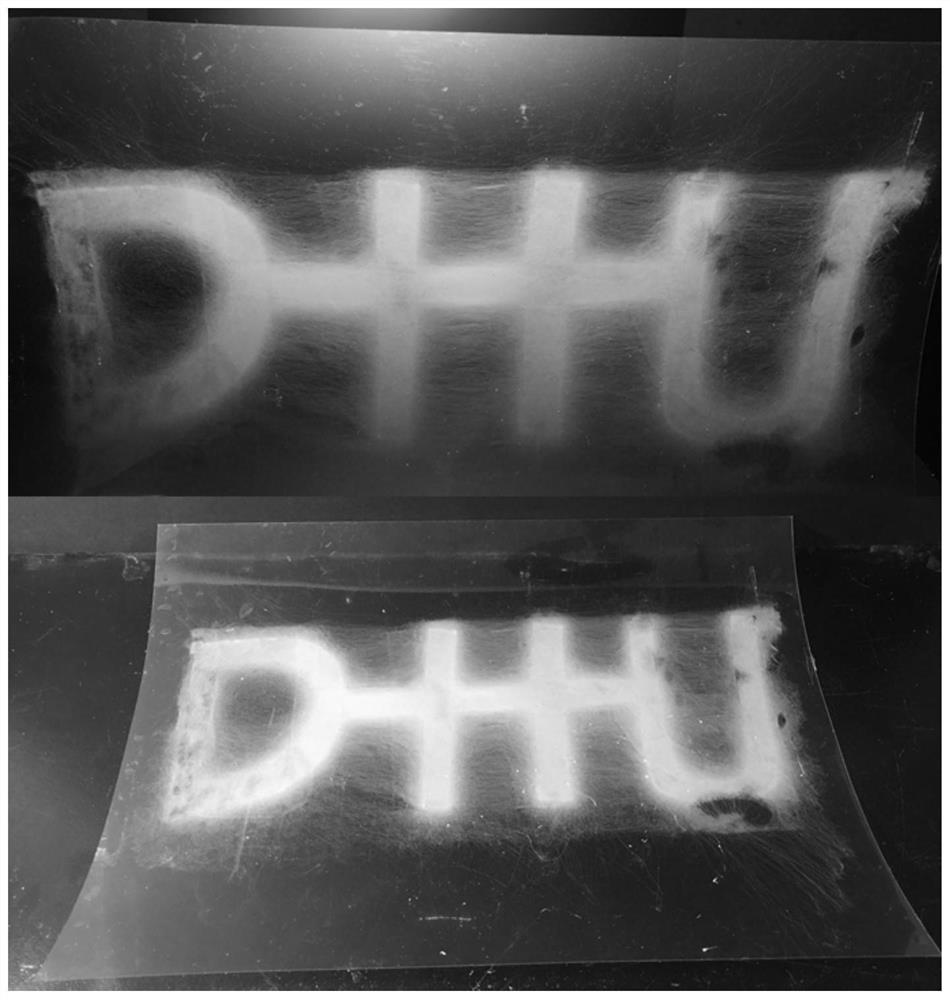

Embodiment 1

[0041] Dissolve 4g of polystyrene in 10ml of N,N-dimethylformamide and 10ml of tetrahydrofuran in a mixed solvent, stir magnetically for 8 hours until completely dissolved, and obtain polystyrene spinning with a concentration of 20% (W / V, g / ml). silk liquid. Select a 10ml syringe with a needle with an inner diameter of 0.25mm, and fix the syringe for drawing 4ml of polystyrene spinning solution on the syringe pump. Electrospinning process parameters are: voltage 11kV, injection pump flow rate 1.2ml / h, receiving distance 18cm, ambient temperature 25°C, and ambient relative humidity 50%. Using an insulating polyester receiving substrate and a conductive backplane with a letter "DHU" pattern, the conductivity of the conductive backplane is 3.77×10 3 S / m, it needs to be grounded to form an electrostatic field, and finally a fiber aggregate with a "DHU" pattern is obtained on a polyester receiving substrate. Such as figure 1 As shown, a patterned fiber assembly was obtained usi...

Embodiment 2

[0043] Dissolve 4 g of polystyrene in 10 ml of N,N-dimethylformamide and 10 ml of tetrahydrofuran mixed solvent, and magnetically stir for 8 hours until completely dissolved to obtain a polystyrene spinning solution with a concentration of 20% (W / V). Select a 10ml syringe with a needle with an inner diameter of 0.25mm, and fix the syringe for drawing 4ml of polystyrene spinning solution on the syringe pump. Electrospinning process parameters are: voltage 11kV, injection pump flow rate 1.2ml / h, receiving distance 18cm, ambient temperature 25°C, and ambient relative humidity 50%. Figure 6 The composite template is used as the receiving device, where a is the grounding point of the conductive aluminum foil, b is the smooth insulating polyester receiving substrate, and c is the conductive patterned aluminum foil paper backing board. Figure 7 a is based on Figure 6 The physical picture of the "mouth" patterned fiber assembly obtained for the receiving device, Figure 7 b is a ...

Embodiment 3

[0045] Dissolve 4g of polystyrene and 0.4g of cellulose acetate in 10ml of N,N-dimethylformamide and 10ml of tetrahydrofuran mixed solvent, and magnetically stir for 8h until completely dissolved to obtain polystyrene-cellulose acetate mixed spinning solution. Select a 10ml syringe, a needle with an inner diameter of 0.25mm, draw out a syringe of 4ml of the mixed spinning solution and fix it on the syringe pump. Electrospinning process parameters are: voltage 11kV, injection pump flow rate 1.2ml / h, receiving distance 18cm, ambient temperature 25°C, and ambient relative humidity 50%. Such as Figure 9 The composite template is shown as the receiving device, where a is the smooth insulating polyester receiving substrate, b is the grounding part of the conductive aluminum foil, and c is the back plate of the conductive patterned aluminum foil paper. Such as Figure 10 shown in Figure 9 Physical image of the "DHU" patterned fiber assembly obtained for the receiving device. F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com