A method for separating and melting high-arsenic and high-lead copper alloy

A copper alloy and high-lead technology, applied in the field of metal smelting, can solve the problems of serious arsenic pollution, high pressure of impurity removal, high pressure of wastewater treatment, etc., and achieve the effect of high smelting efficiency, small flue gas volume and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

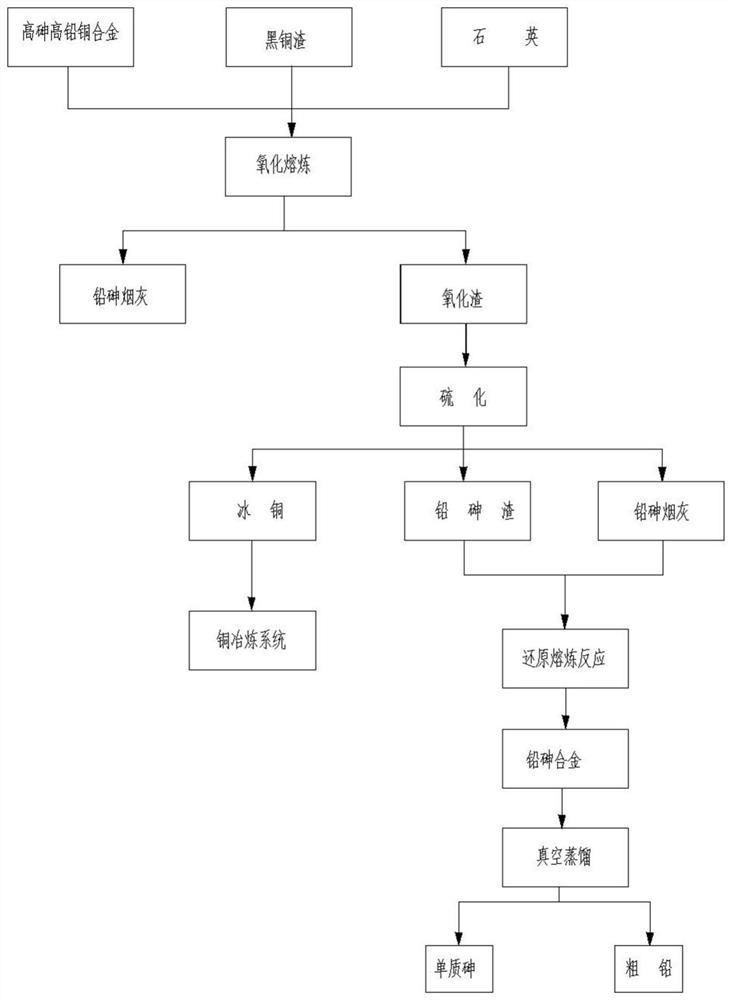

Image

Examples

Embodiment 1

[0029] The main components and weight percentages of the high-arsenic high-lead copper alloy used in this embodiment are respectively Cu 28%, Pb 26%, As 22%; the main components and weight percentages of the described black copper slag are respectively Cu 45%, As 18%.

[0030] The detailed steps of the separation and smelting method of the high-arsenic high-lead copper alloy of the present invention are as follows:

[0031] a. Mix high-arsenic and high-lead copper alloy, black copper slag and quartz according to the weight ratio of 100:10:10, and then put them into the bottom blowing furnace for oxidation smelting; during the oxidation smelting process, control the melting temperature to 1150°C, During the smelting process, oxygen and natural gas are fed into the melt through an oxygen lance for heating and oxidation, and the ratio of oxygen to material is 90m 3 / ton of material, the volume ratio between oxygen and natural gas is 3.2:1; lead-arsenic soot and copper-arsenic-l...

Embodiment 2

[0039] The main components and weight percentages of the high-arsenic high-lead copper alloy used in this embodiment are respectively Cu 32%, Pb 23%, As 21%; the main components and weight percentages of the described black copper slag are respectively Cu 35%, As 25%.

[0040] The detailed steps of the separation and smelting method of the high-arsenic high-lead copper alloy of the present invention are as follows:

[0041] a. Mix high-arsenic and high-lead copper alloy, black copper slag and quartz according to the weight ratio of 100:10:13, and then put them into the bottom blowing furnace for oxidation melting; during the oxidation melting process, the melting temperature is controlled at 1180°C, and the oxidation During the smelting process, oxygen and natural gas are fed into the melt through an oxygen lance for heating and oxidation, and the ratio of oxygen to material is 110m 3 / ton of material, the volume ratio between oxygen and natural gas is 3.6:1; lead-arsenic so...

Embodiment 3

[0049] The main components and weight percentages of the high-arsenic high-lead copper alloy used in this embodiment are respectively Cu22%, Pb30%, As 30%; the main components and weight percentages of the described black copper slag are Cu 50% respectively. %, As 15%.

[0050] The detailed steps of the separation and smelting method of the high-arsenic high-lead copper alloy of the present invention are as follows:

[0051] a. Mix high-arsenic and high-lead copper alloy, black copper slag and quartz according to the weight ratio of 100:10:15, and then put them into the bottom blowing furnace for oxidation melting; during the oxidation melting process, the melting temperature is controlled at 1100°C, and the oxidation During the smelting process, oxygen and natural gas are fed into the melt through the oxygen lance for heating and oxidation, and the ratio of oxygen to material is 75m 3 / ton of material, the volume ratio between oxygen and natural gas is 3.0:1; lead-arsenic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com