Filament wick column horn cooling device

A cooling device and wick post technology, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of low scrap rate, low strength, high scrap rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

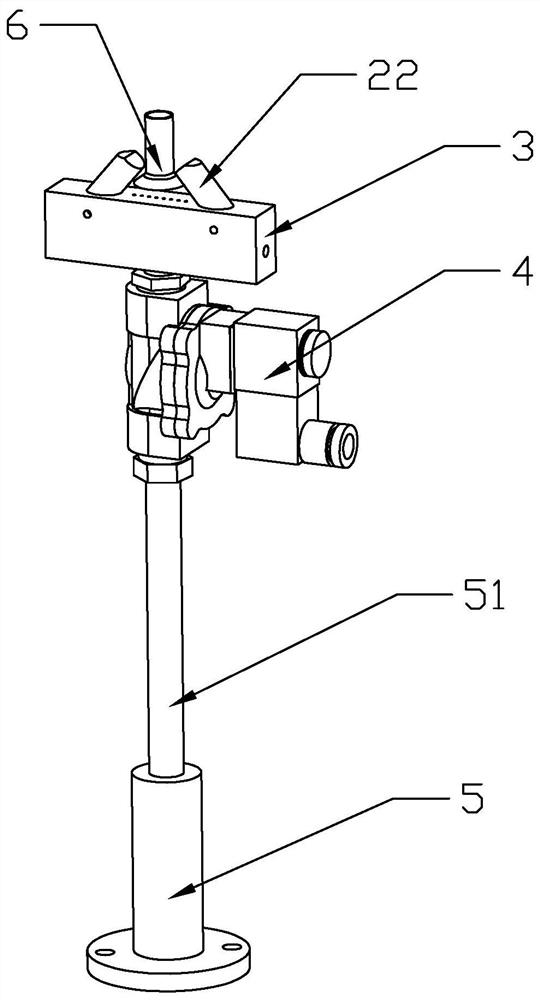

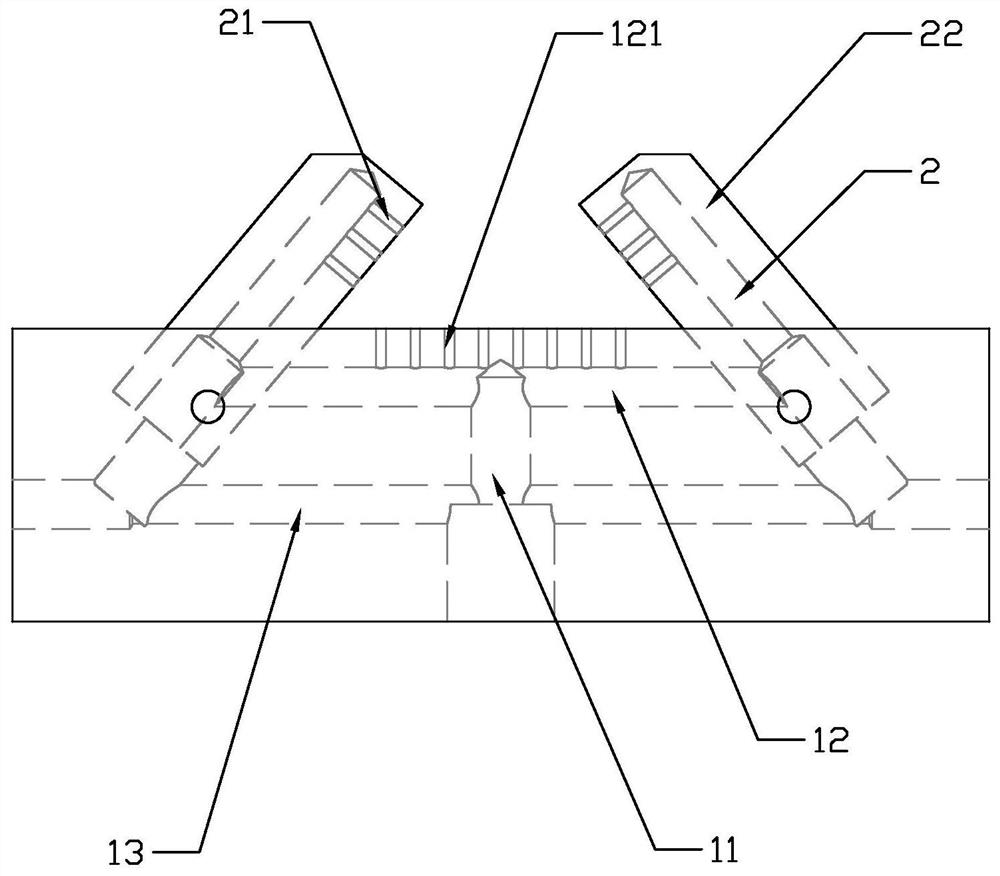

[0030] Such as figure 1 , figure 2 In the shown embodiment 1, a filament lamp stem horn cooling device includes a middle air pipe 1, a side air pipe 2, an air distributor 3 and a solenoid valve 4. The air distributor 3 is in the shape of a cuboid as a whole, and the air distributor 3 There is a middle air pipe 1 inside, and the middle air pipe 1 includes a vertical main pipe 1, the bottom of the main pipe 1 is connected to the solenoid valve 4 through a variable diameter joint, and the other end of the solenoid valve 4 is connected to the high-pressure air supply system. Wherein the high-pressure air supply system is a high-pressure fan, which is a prior art. The bottom of the main pipe 1 is horizontally connected to both sides with a second branch pipe 13, the top of the main pipe 1 is horizontally connected to both sides with a branch pipe 12, and the top of the branch pipe 12 is connected with a number of vertical middle air outlets 121 along the extension direction of th...

Embodiment 2

[0033] A kind of cooling device for the horn of the filament lamp stem, the structure of which is roughly the same as that of Embodiment 1, the difference is that the top of the air distributor 3 is provided with a groove, and the side pipe bracket 22 is rotated and arranged in the groove, which can be adjusted according to different shapes. The bell mouth adjusts the angle of the side pipe bracket 22 to ensure that the side air outlet 21 is perpendicular to the side of the bell mouth, and the distance between each side air outlet 21 and the side of the bell mouth is consistent, and the applicable product range is wider; several middle air outlets 121 are in the air distributor 3 The center of the top surface is evenly distributed in a circular range, and the circular area is larger than the projected area of the bell mouth on the top surface of the air distributor. This structure ensures uniform cooling inside the bell mouth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com