New type opeed changing transmission

A transmission device and variable speed transmission technology, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of vehicles not being too impulsive, high speed, and fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] 1. Auxiliary drive with fixed feedback input from the center wheel - stepless main drive transmission.

[0110] At present, all kinds of centrifugal continuously variable V-belt variable speed motorcycles use the engine speed to control the transmission ratio, and the working principle of the centrifugal continuously variable variable speed automobile introduced above is also the same, and they all belong to the single parameter control method. According to its shortcoming, redesign a kind of continuously variable speed vehicle, has adopted fixed feedback auxiliary transmission——continuously variable main transmission transmission.

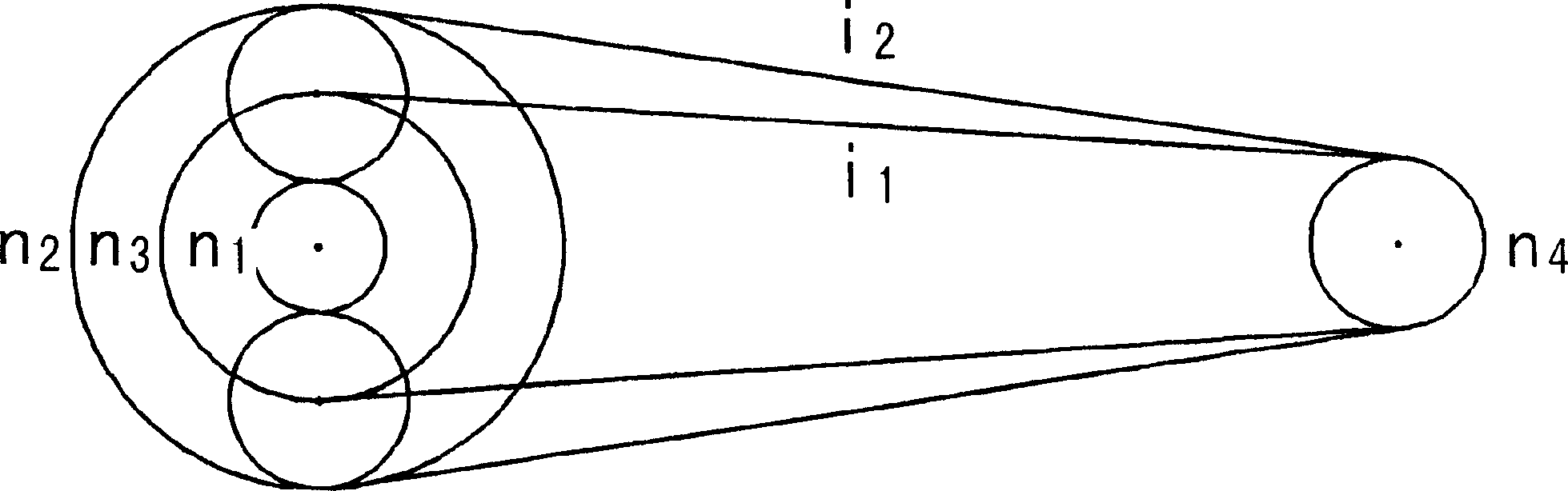

[0111] See the principle of fixed feedback centrifugal continuously variable V-belt transmission Figure 8 .

[0112]The rotational speed and power of the crankshaft of the engine 2 are input by the center wheel 3 of the planetary system, the planet carrier 4 is connected with the centrifugal rotor 8 and the driving wheel 7, the ring gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com