c 3 n 4 Synthesis method, product and application of quantum dot room temperature phosphorescent material

A room-temperature phosphorescence and synthesis method technology, applied in the field of materials, can solve problems such as high cost, limitation, and cytotoxicity, and achieve the effect of expanding the application range and enriching the synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] With urea as reactant C 3 N 4 The synthesis of quantum dot room temperature phosphorescent materials, the specific steps are as follows:

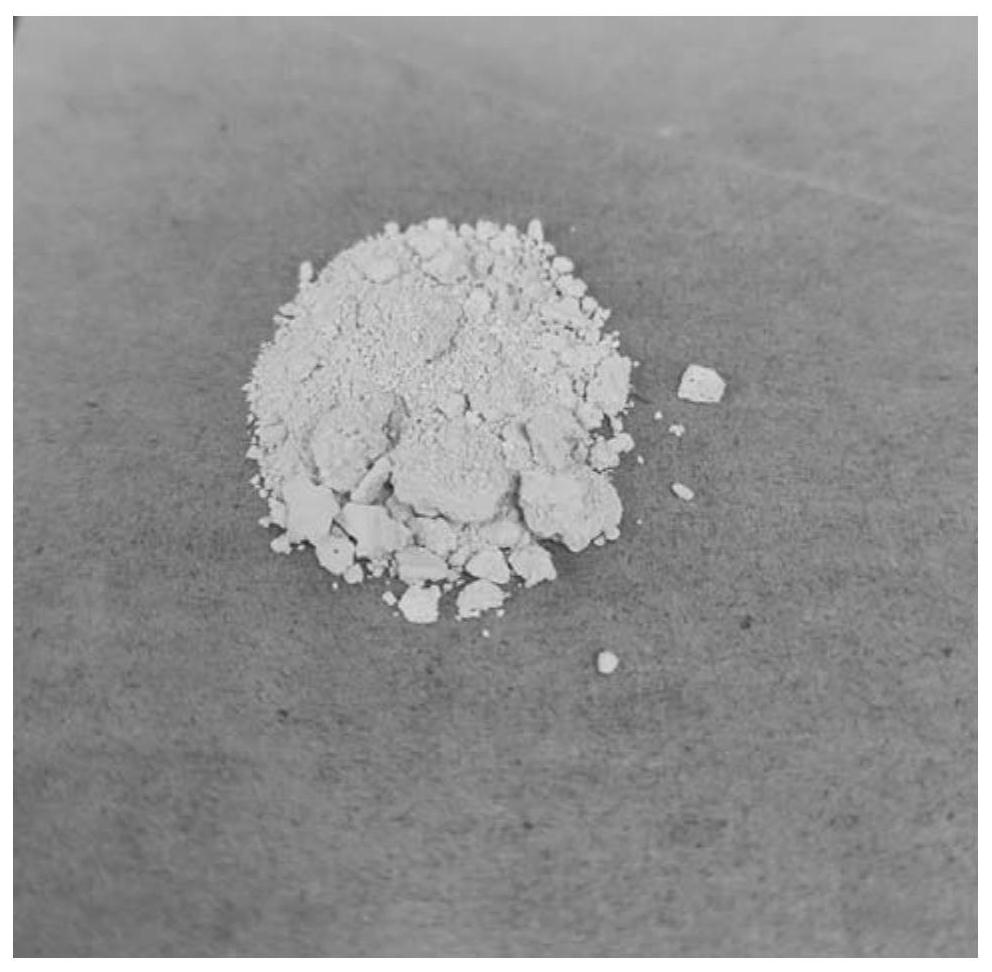

[0028] (1) After grinding 20g of urea into off-white flour, transfer it to a reactor made of quartz glass with a volume of 50mL;

[0029] (2) The liner is then loaded into a high-temperature and high-pressure reactor according to the regular process;

[0030] (3) Set the reaction temperature to 300°C, the pressure to 8Mpa, the time to 3h, and the stirrer speed to 500rpm;

[0031] (4) After the reaction is over, wait for the reactor program to return to normal temperature and pressure, take out the liner and scrape the yellow-brown crude product;

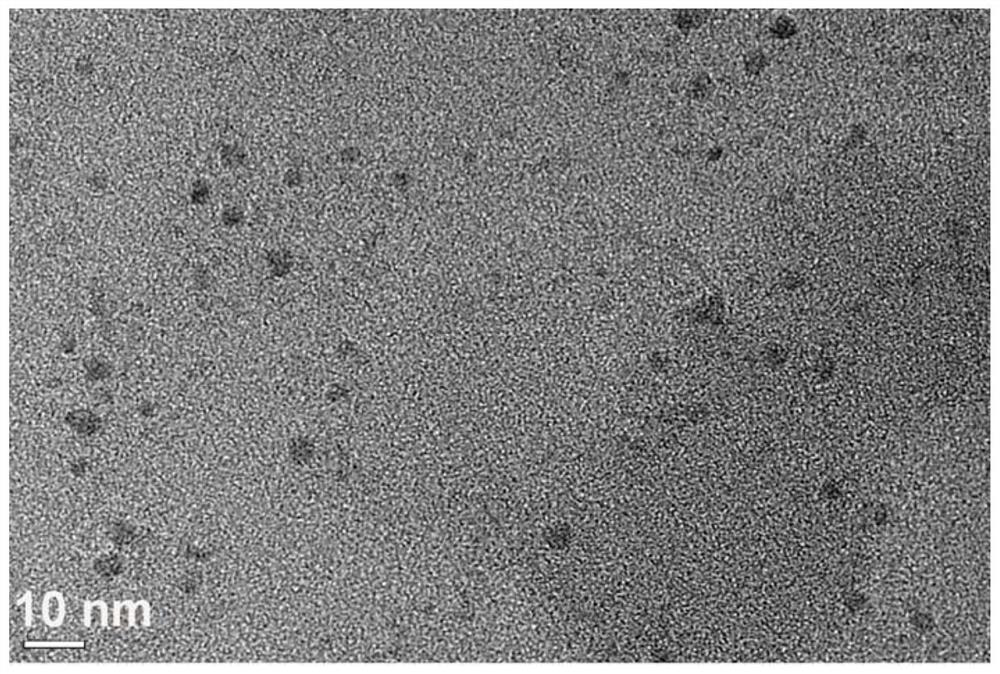

[0032] (5) Ultrasonic dispersion of the crude product in an aqueous solution, followed by suction filtration with a filter membrane with a pore size of 220 nm;

[0033] (6) wash with dilute hydrochloric acid and ethanol successively, neutralize the product and remove other organic by-pr...

Embodiment 2

[0036] With hydroxyurea as reactant C 3 N 4 The synthesis of quantum dot room temperature phosphorescent materials, the specific steps are as follows:

[0037] (1) Grinding 10g of hydroxyurea into an off-white flour and transferring it to a reactor made of quartz glass with a volume of 50mL;

[0038] (2) The liner is then loaded into a high-temperature and high-pressure reactor according to the regular process;

[0039] (3) Set the reaction temperature as 250°C, the pressure as 4Mpa, the time as 2h, and the stirring bar rotating speed as 800rpm;

[0040] (4) After the reaction is over, wait for the reactor program to return to normal temperature and pressure, take out the liner and scrape the brown crude product;

[0041] (5) Ultrasonic dispersion of the crude product in an aqueous solution, followed by suction filtration with a filter membrane with a pore size of 220 nm;

[0042] (6) wash with dilute hydrochloric acid and ethanol successively, neutralize the product and r...

Embodiment 3

[0045] The synthesis of C3N4 quantum dot room temperature phosphorescent material with biuret as reactant, the specific steps are as follows:

[0046] (1) After grinding 15g of biuret into off-white flour, transfer to a reactor made of quartz glass with a volume of 50mL;

[0047] (2) The liner is then loaded into a high-temperature and high-pressure reactor according to the regular process;

[0048] (3) Set the reaction temperature to 270°C, the pressure to 5Mpa, the time to 3h, and the stirring bar speed to 500rpm;

[0049] (4) After the reaction is over, wait for the reactor program to return to normal temperature and pressure, take out the liner and scrape the brown crude product;

[0050] (5) Ultrasonic dispersion of the crude product in an aqueous solution, followed by suction filtration with a filter membrane with a pore size of 220 nm;

[0051] (6) wash with dilute hydrochloric acid and ethanol successively, neutralize the product and remove other organic by-products;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com