Powder storage tank

A technology for storage tanks and powders, applied in the direction of loading/unloading, containers, packaging, etc., which can solve the problems of general arch breaking effect, loud noise, and poor fluidity of the pneumatic vibrator 12, and achieve ingenious and economical installation positions and installation methods High efficiency and good arch breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

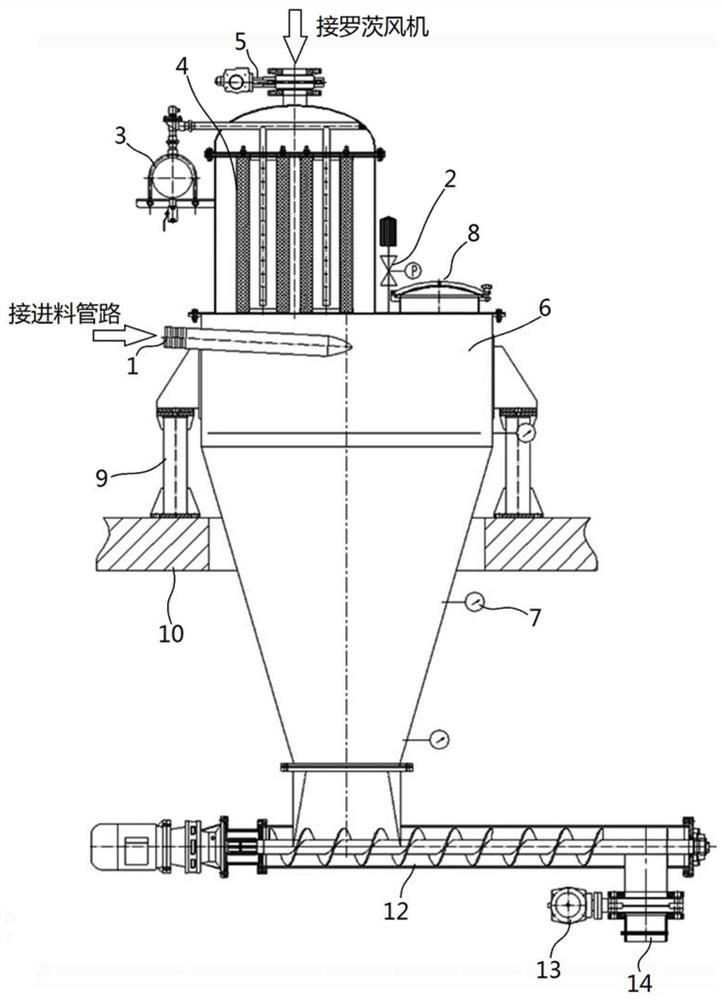

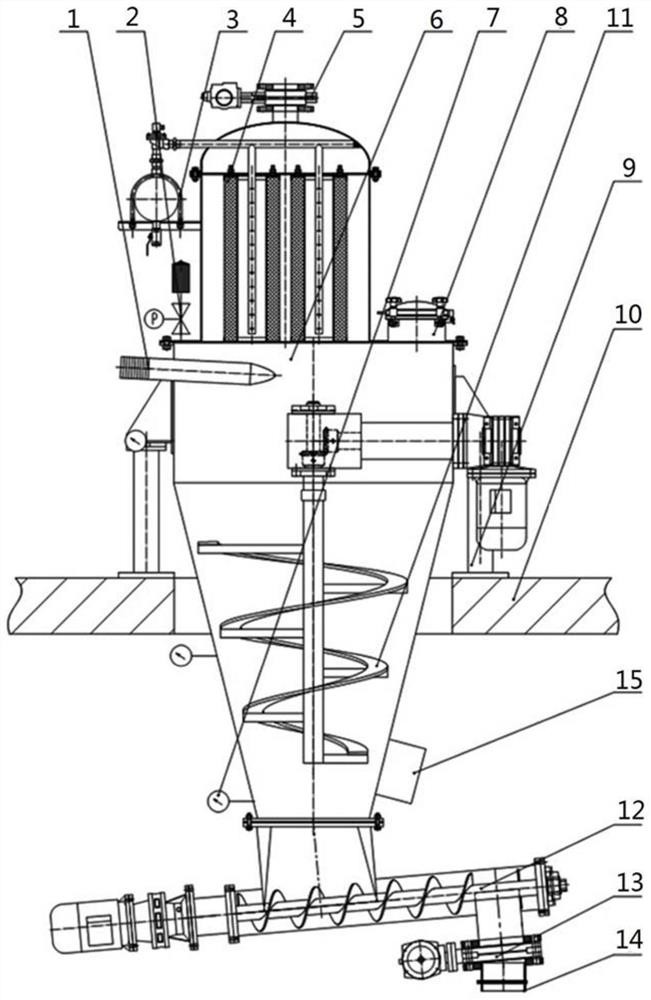

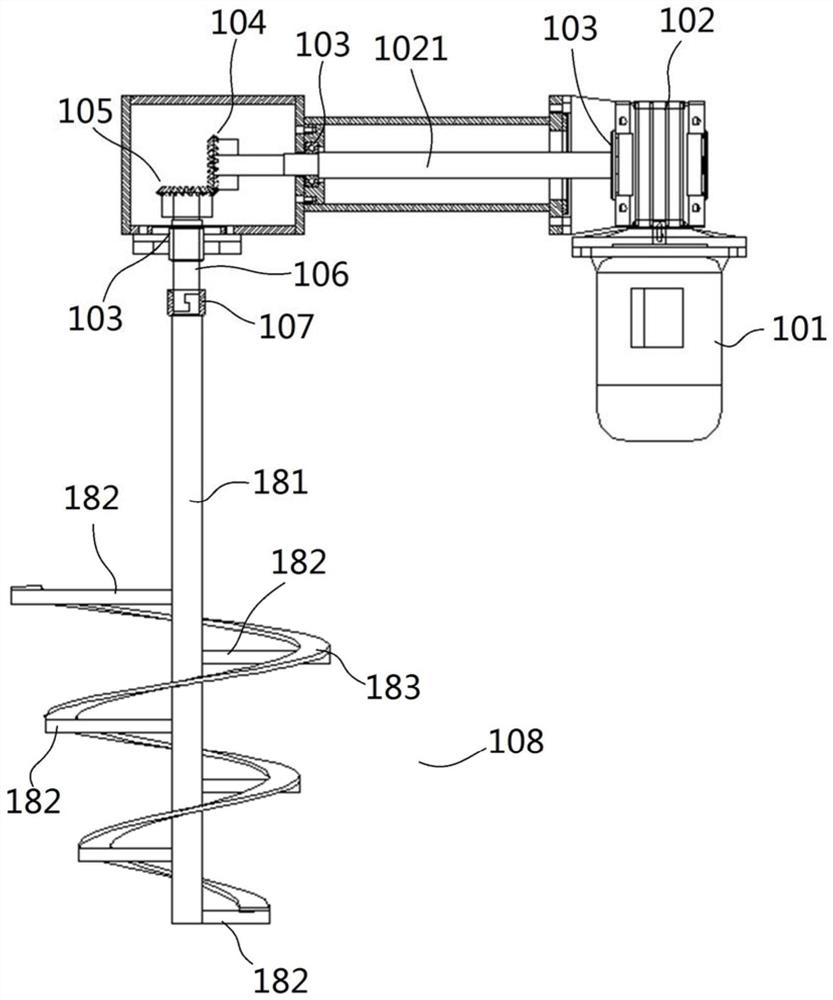

[0022] A specific embodiment of a powder storage tank of the present invention, such as Figure 2-Figure 3 As shown, the powder storage tank includes a tank body 6 with a conical bottom, and a feed pipe 1 is arranged on the top of the tank body 6, and the feed pipe 1 is welded on the top of the tank body 6. The tank body 6 has a top cover, and the top cover is provided with a There are respirator 2, reverse blowing air bag assembly 3, gas material separator 4 and suction port, the suction port is provided with a pneumatic butterfly valve, the lower end of the tank body 6 is provided with a screw conveyor 12, and the screw conveyor 12 is self-contained from the feed end It is arranged inclined upward towards the discharge end, and the tank body 6 is provided with an arch breaking mechanism 11, which includes a drive motor 101, a reduction box 102 (with a reduction mechanism inside), and a bearing box (with a bearing 103 inside) that are sequentially connected by transmission. ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com