A grinding tool for a ball cage cage with adjustable position and angle

A technology of cage and ball cage, which is applied in the direction of grinding machines, manufacturing tools, grinding drive devices, etc., can solve the problems of inability to grind and polish rectangular windows, insufficient polishing, limited diameter and length, etc., and achieve simple and efficient removal and removal operations. Easy to use, efficient and economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

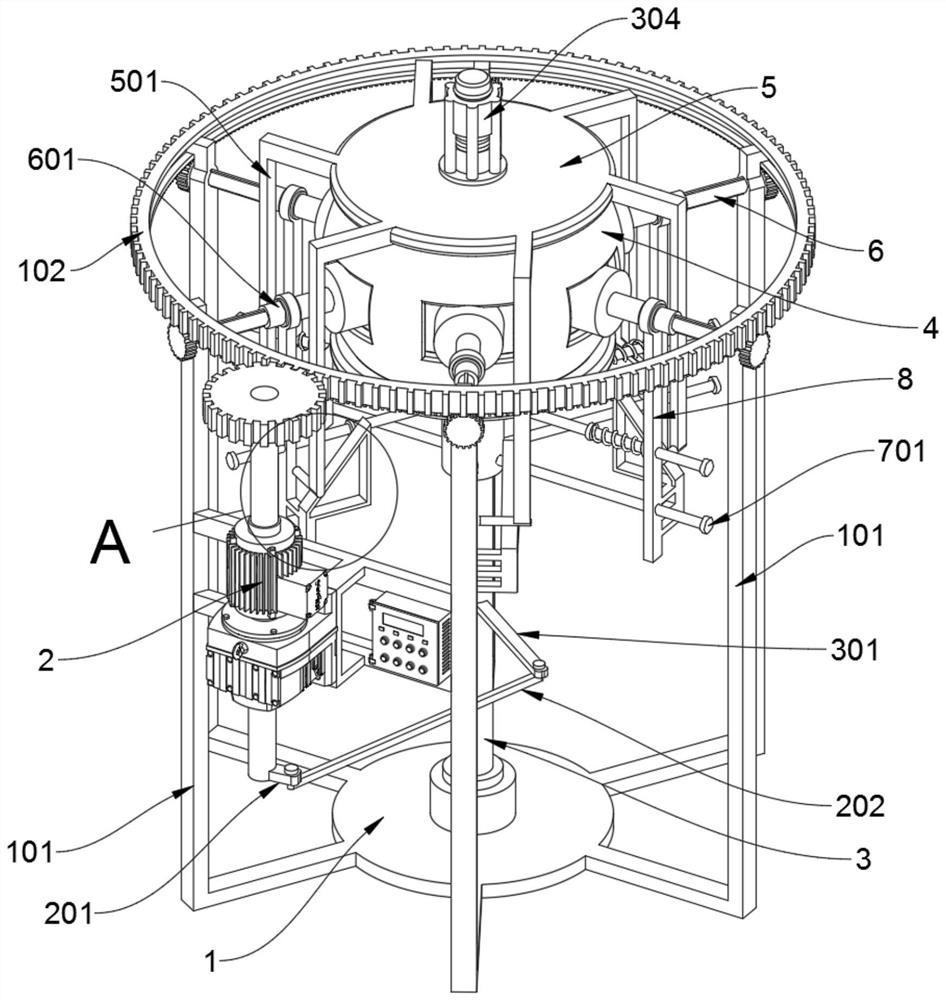

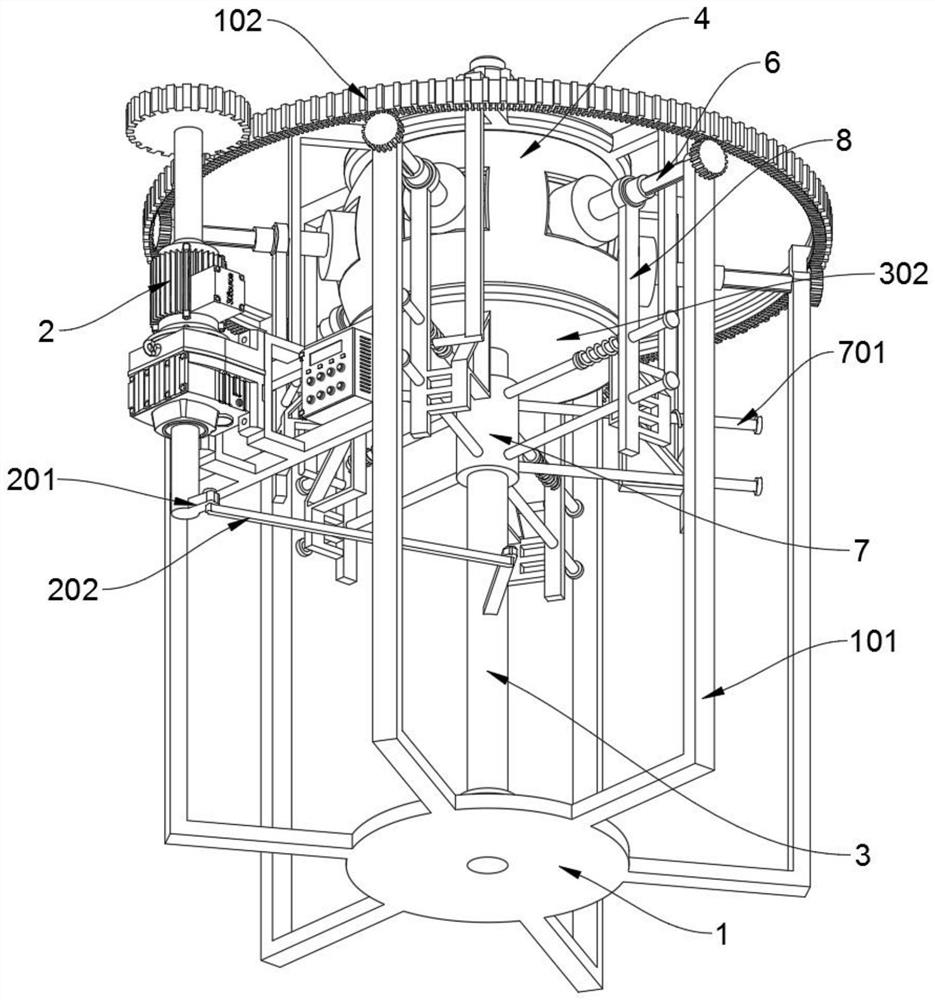

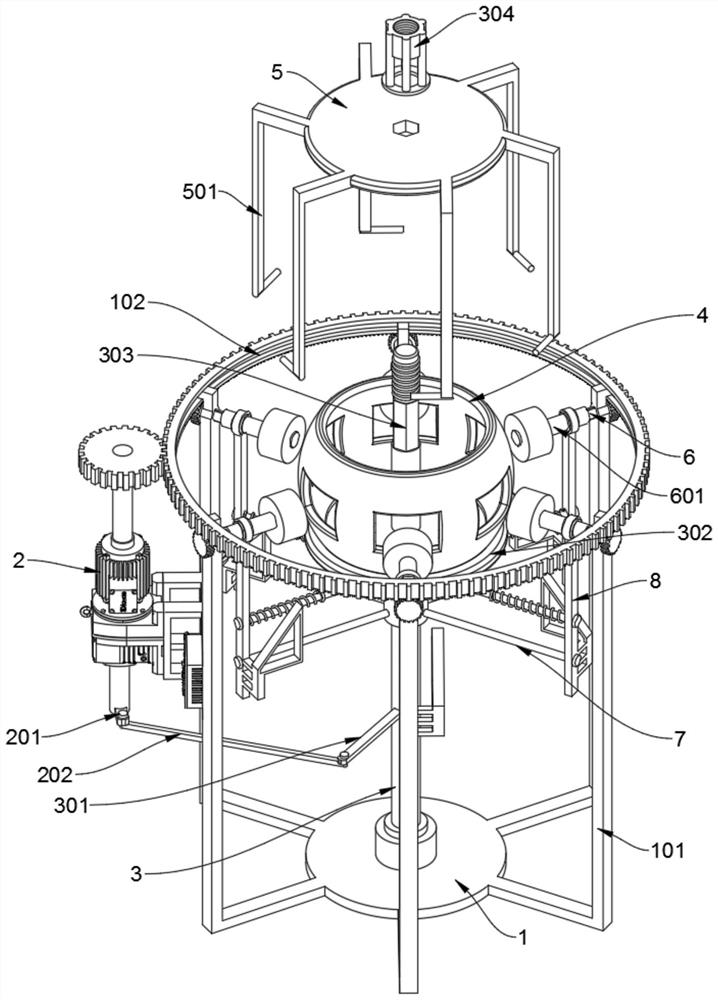

[0030] see Figure 1 to Figure 8 , an embodiment provided by the present invention: a grinding tool for a ball cage with adjustable position and angle, including a base 1, the base 1 includes a vertical support leg 101 and a gear ring 102, the base 1. The whole is formed by the joint welding combination of the central circular chassis and the six vertical legs 101 supported in a circular array. The tops of the six vertical legs 101 are all welded and supported with an L positioning claw, and the ring gear 102 is rotated Installed on the six L positioning claws; a motor assembly 2 is vertically locked on the middle section of the two vertical support legs 101 on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com