Water-in-oil type high-internal-phase Pickering emulsion as well as preparation method and application thereof

A high internal phase emulsion and water-in-oil type technology, which is applied in the field of water-in-oil type high internal phase Pickering emulsion and its preparation, can solve the problems of application limitation, low stability, and no application of functional oil diglycerides. Achieve the effects of strong physiological activity, increased system stability, and excellent Pickering interface crystallization characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

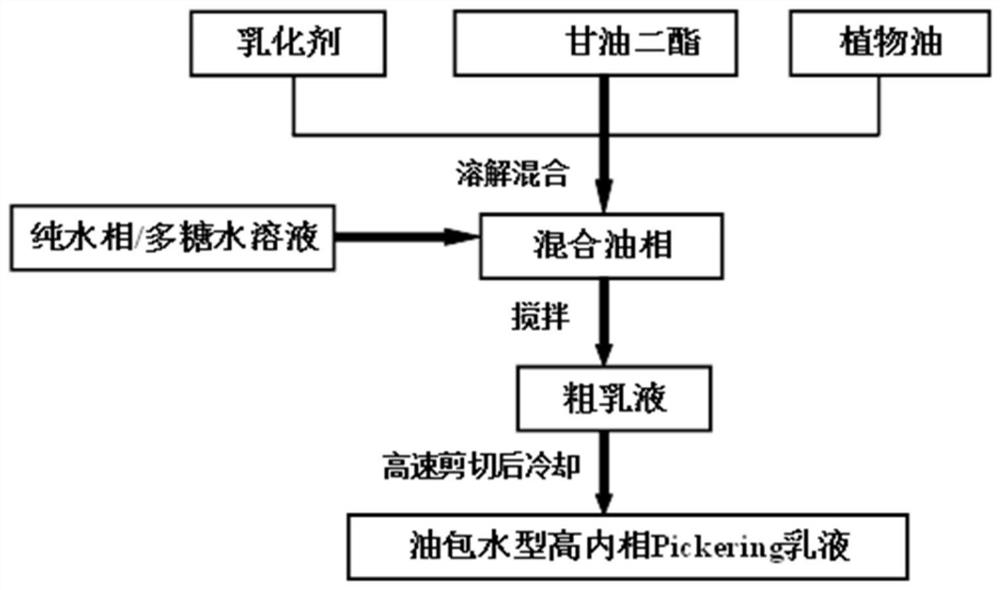

Method used

Image

Examples

Embodiment 1

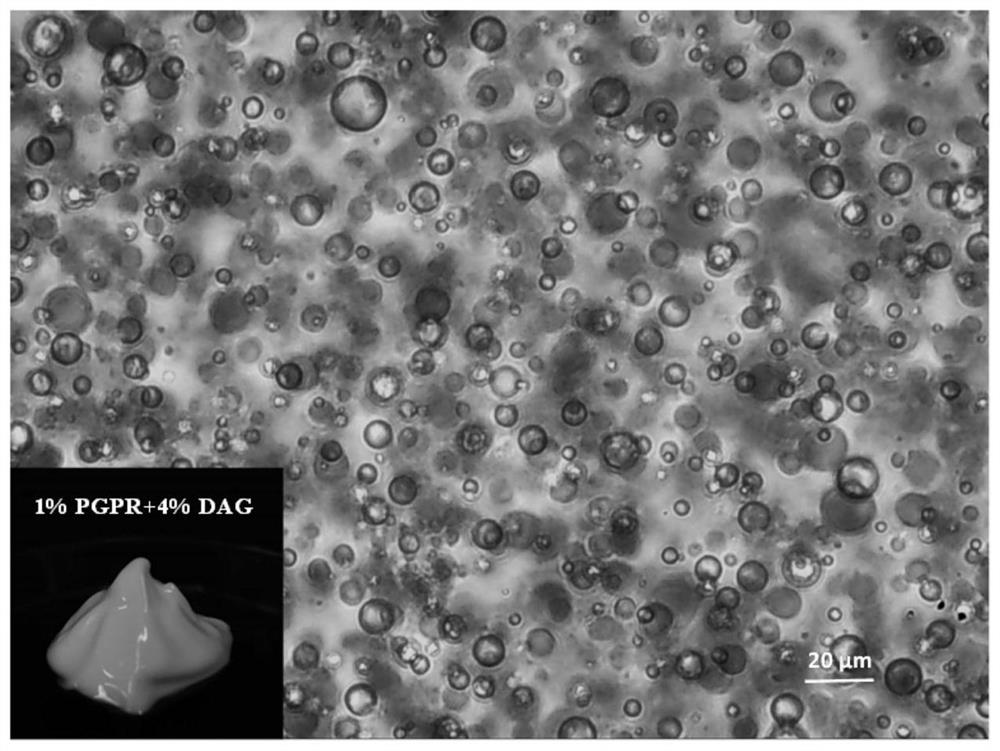

[0044] (1) get the long-chain diglyceride containing stearic acid and palmitic acid, the purity is about 60%, and place in the same beaker with a certain amount of emulsifier polyglycerol ricinoleate (PGPR) and rapeseed oil, Among them, long-chain diglycerides accounted for 4% of the total oil phase, PGPR accounted for 1% of the water phase, and the volume ratio of the oil phase and the water phase was 25:75. Magnetic stirring made the oil phase temperature reach 85 °C, and then Water preheated to 85° C. was slowly added dropwise to the well-mixed oil phase, and the water phase and the oil phase were fully mixed at 700 rpm for 5 min to obtain a coarse emulsion with a volume percentage of 75% of the water phase.

[0045] (2) The coarse emulsion obtained in step (1) was sheared and homogenized at 15000rpm for 5min with a high-speed disperser, and the temperature of the water bath was maintained at about 85°C during the emulsification process. Finally, the sheared emulsion was co...

Embodiment 2

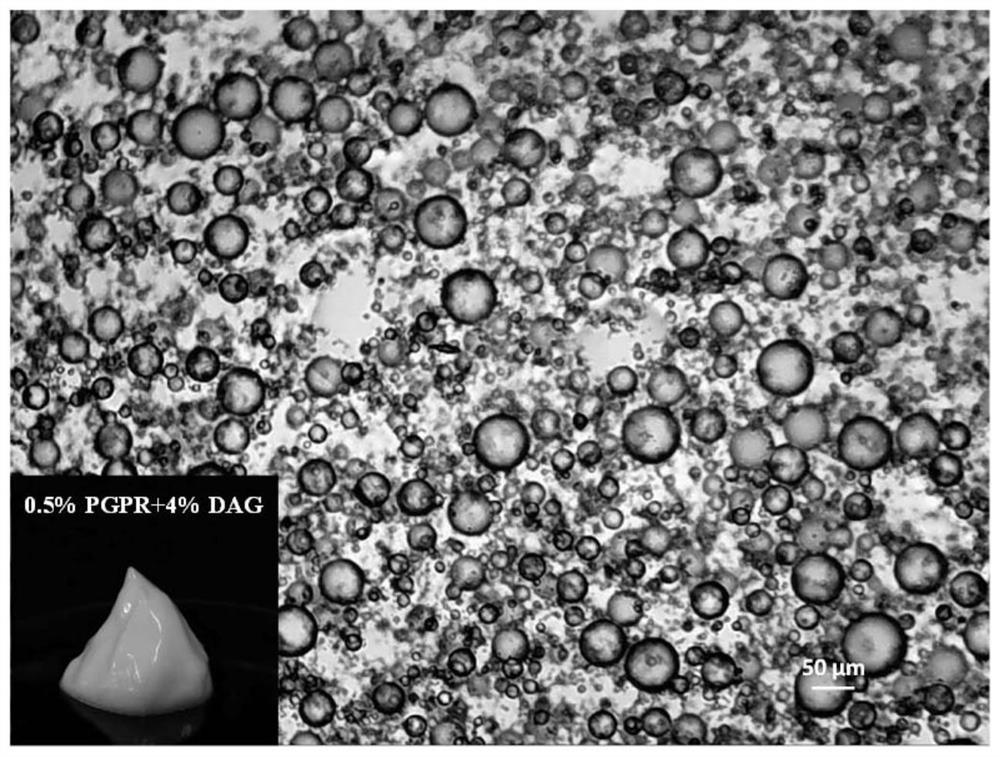

[0050] (1) steps and conditions of reference example 1, the difference is that in step (1), diglyceride is medium and long chain diglyceride, contains medium chain lauric acid and long chain stearic acid, and the diglyceride purity is about 70%; in step (2), the emulsifier polyglycerol ricinoleate (PGPR) accounts for 0.5% of the mass of the water phase, magnetic stirring makes the oil phase temperature reach 70°C, and then the water preheated to 70°C is slowly dripped It was added to the well-mixed oil phase, and the water phase and the oil phase were fully mixed for 5 min at 700 rpm to obtain a coarse emulsion with a volume percentage of the water phase of 75%.

[0051] During the emulsification process, the temperature of the water bath was maintained at about 70°C. A high internal phase water-in-oil emulsion with a water phase volume percentage of 75% was prepared.

[0052] The plastic appearance and microstructure of the water-in-oil Pickering emulsion prepared in Example...

Embodiment 3

[0054] (1) steps and conditions of reference example 1, the difference is that in step (2), diglyceride accounts for 8% of the total oil phase mass ratio, and the water phase is the agar aqueous solution of heating and dissolving, and vegetable oil is soybean oil, prepared The internal phase is a coarse emulsion of an aqueous polysaccharide solution.

[0055] (2) The coarse emulsion obtained in step (1) was rapidly sheared and homogenized at 12000rpm for 6min with a high-speed disperser, and the temperature of the water bath was maintained at about 80°C during the emulsification process. Finally, the sheared emulsion was cooled and crystallized with a magnetic stirrer at a stirring rate of 1000 rpm to obtain a stable emulsion, which was stored at 5°C.

[0056] Different from Example 1, in Example 3, the mass ratio of agar in the aqueous agar solution to the water phase was 1%. Through this example, a high internal phase emulsion with an internal phase of 75% water phase can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com