Water-soluble film, method for producing same, and pharmaceutical package

A water-soluble film and packaging technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of reduced production efficiency, position deviation, and difficult handling of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

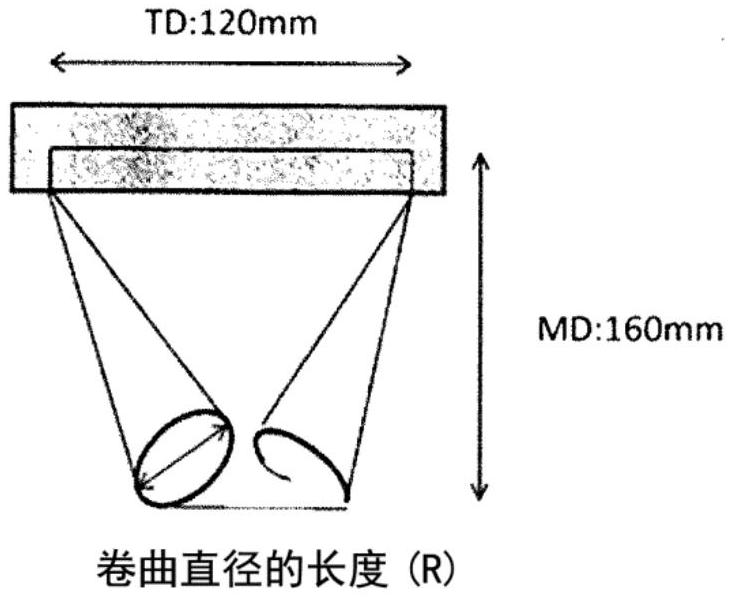

Method used

Image

Examples

Embodiment

[0195] Although an Example is given below and this invention is demonstrated more concretely, this invention is not limited to the following Example unless the summary is exceeded.

[0196] In addition, in an example, "part" and "%" mean a weight basis.

[0197]

[0198] Carboxyl-modified PVA ( A1) 90 parts, 10 parts of unmodified PVA (A2) with a 4% aqueous solution viscosity of 18 mPa·s and an average degree of saponification of 88 mol % at 20 ° C, 20 parts of sorbitol (b1) as plasticizer (B) and 20 parts of glycerin (b2), 8 parts of starch (average particle diameter 20 μm) as filler (C), 0.2 part of polyoxyalkylene alkyl ether phosphate monoethanolamine salt as surfactant (D) and water are mixed, Dissolution treatment was performed to obtain a starch-dispersed PVA-based resin aqueous solution (solid content concentration: 30%).

[0199] Next, using the above-mentioned PVA-based resin aqueous solution, a film was formed according to the cast film-forming method by a belt-...

Embodiment 2

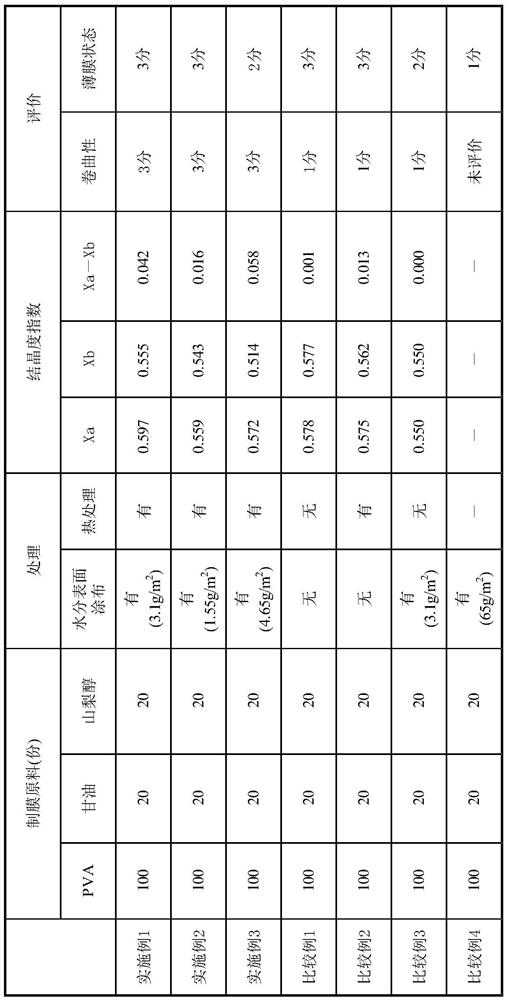

[0219] In Example 1, the coating amount of water was changed to 1.55g / m 2 , except that, a PVA-based water-soluble film having a water content of 8.5% was obtained in the same manner. For the obtained PVA-based water-soluble film, the result of measuring the crystallinity index of the film surface represented by the aforementioned formula (1) by infrared spectroscopic analysis using the attenuated total reflection method (ATR method), Xa=0.559, Xb=0.543 , Xa-Xb is 0.016.

[0220] The obtained water-soluble film was evaluated in the same manner as in Example 1 for curling and film state. The results are shown in Table 1.

Embodiment 3

[0222] In Example 1, the coating amount of water was changed to 4.65g / m 2 , except that, a PVA-based water-soluble film having a water content of 11.4% was obtained in the same manner. For the obtained PVA-based water-soluble film, the results of measuring the crystallinity index of the film surface represented by the aforementioned formula (1) by infrared spectroscopic analysis using the attenuated total reflection method (ATR method), Xa=0.572, Xb=0.514 , Xa-Xb is 0.058. The obtained water-soluble film was evaluated in the same manner as in Example 1 for curling and film state. The results are shown in Table 1.

[0223]

[0224] In Example 1, a PVA-based water-soluble film having a moisture content of 7% was obtained in the same manner except that the moisture surface coating and heat treatment were not performed. For the obtained PVA-based water-soluble film, the results of measuring the crystallinity index of the film surface represented by the aforementioned formula ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com