Battery module temperature sensor and battery module

A technology of temperature sensor and battery module, applied in the field of temperature sensor, can solve the problem that the direct monitoring of the highest temperature of the module cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

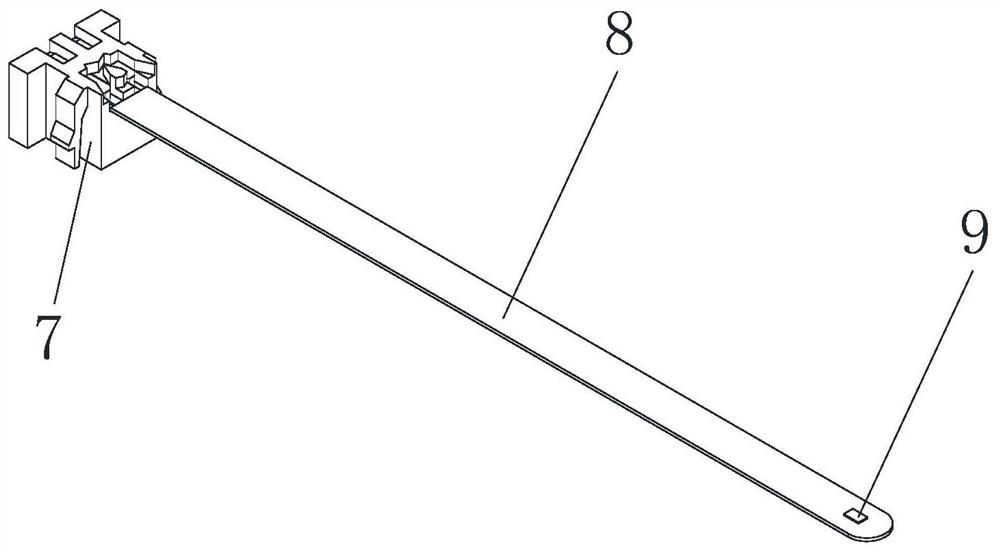

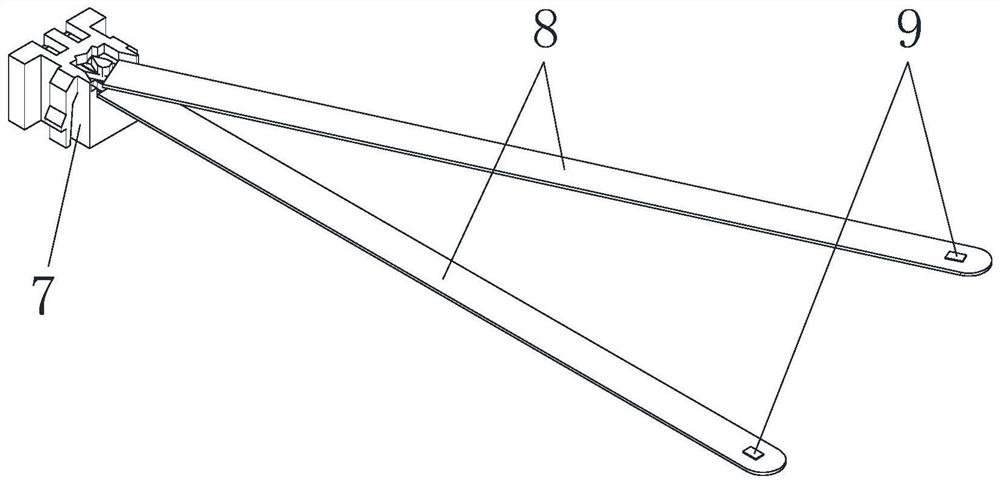

[0038] Such as figure 2 , image 3 , Figure 4 , Figure 5 Shown is Embodiment 1 of the present invention, in which a battery module temperature sensor is provided, including a temperature probe 9, a flexible thin film circuit 8 and a sensor plug connector 7, the temperature probe 9 is arranged at the lower end of the flexible thin film circuit 8, The upper end of the flexible film circuit 8 is connected to the sensor plug connector 7, and the sensor plug connector 7 is also connected to the battery management system sampling harness to realize signal transmission. The temperature probe 9 is arranged between the cells of the battery module to collect temperature signals. Installed and fixed on the module bracket of the battery module, specifically, the sensor plug connector 7 is installed and fixed at the end of the battery module.

[0039] The battery management system sampling harness is also called the BMS sampling line, which is a type of flexible circuit board and can...

Embodiment 2

[0051] Embodiment 2 of the present invention is an improvement made on the basis of Embodiment 1. The difference between Embodiment 2 of the present invention and Embodiment 1 is that: Figure 12 As shown, the sensor plug connector 7 is equipped with a plug-in terminal, the bottom end of the plug-in terminal is electrically connected to the flexible film circuit 8, the plug-in terminal can be a pin 10, and the battery management system sampling harness is provided with a connector 12 The connector 12 is correspondingly provided with a socket 11 , the socket 11 is a metal hole with elasticity, and the connector 12 is combined with the plug-in terminal to realize the electrical connection with the flexible film circuit 8 .

[0052] The bottom end of the contact pin 10 is soldered to the flexible film circuit 8, and the top end protrudes. A slot can be arranged in the sensor plug 7, the top of the pin 10 is located in the slot, and the connector 12 can be inserted into the slot. ...

Embodiment 3

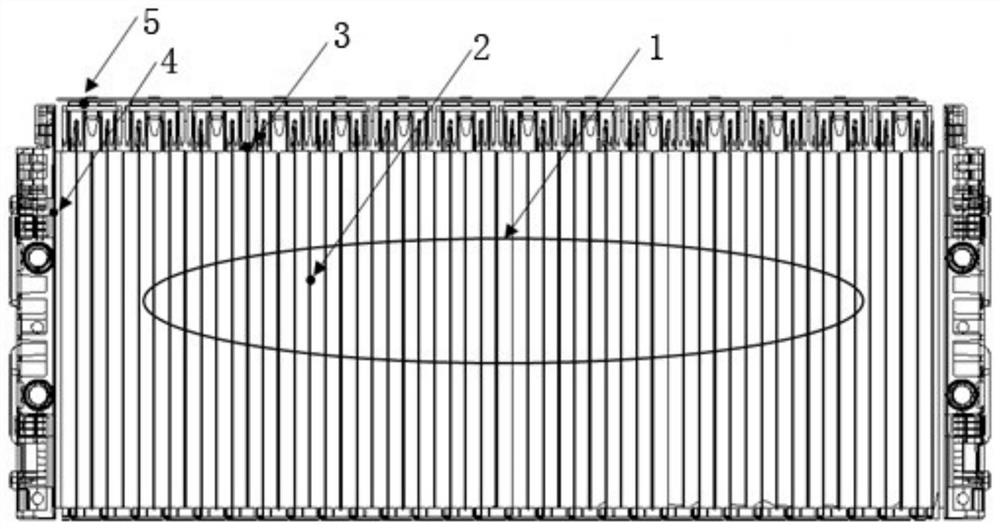

[0055] Such as Figure 8 , Figure 9 , Figure 10 As shown, this embodiment provides a battery module, including a plurality of battery cells 14, and also includes the battery module temperature sensor described in Embodiment 1 or Embodiment 2, the temperature probe 9 and the flexible film of the battery module temperature sensor The circuit 8 is arranged between the cells 14 to collect temperature signals.

[0056] The sensor plug connector 7 of the battery module temperature sensor is connected to the sampling wire harness 13 of the battery management system to realize the electrical connection with the flexible thin film circuit 8 . The battery module is provided with a main interface 15, and the battery management system sampling harness 13 is connected to the main interface 15, and finally transmits signals externally through the main interface 15.

[0057] A flexible foam pad can be provided between the battery cells 14 corresponding to the temperature probes 9 to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com