Method for optimizing glass production link based on glass tin bath mathematical model

A mathematical model and production link technology, applied in the control/adjustment system, comprehensive factory control, instruments, etc., can solve problems such as large deformation, increased lateral temperature difference of glass plates, flatness, uniformity of thickness difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Example 1: Establishment of the mathematical model of the glass tin bath and the working simulation of the glass tin bath

[0089] Step 1, establishment of geometric model:

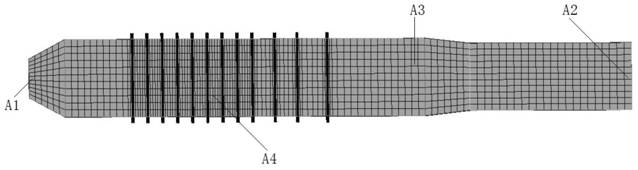

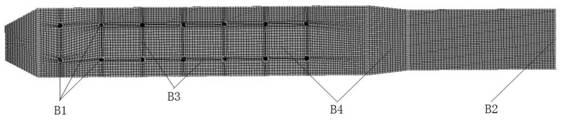

[0090] Taking a 150t / d glass tin bath for the production of medium-alumina glass as a prototype, use GstarCAD software to establish a geometric model including the glass ribbon space and the protective gas space.

[0091] The prototype parameters of the glass tin bath mainly include: the length of the glass tin bath is 37.8 meters, the width of the wide section is 5.2 meters, and the narrow section is 4.5 meters. At 18000mm (the twelfth pair of edge pulling machines), there are 14 air inlets on the top of the glass tin bath, which are symmetrical and arranged in an array with the tin bath axis as the center. Specifically, the wide section is 24m×5.2m (length×width), the length of the shrinking section is 3m, and the width changes linearly, and the narrow section is 10.8m×4.5m (length×width).

[0...

Embodiment 2

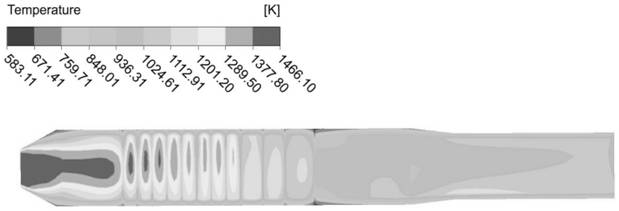

[0159] Example 2: Optimization of the Mathematical Model of the Glass Tin Bath

[0160] Since the actual working state of the glass tin bath is affected by many factors, for example, the speed and temperature of the glass ribbons in the glass tin bath are inconsistent, the number and arrangement of the air inlets. In order to simulate the actual working state of the glass tin bath as realistically as possible, the mathematical model of the glass tin bath can be optimized.

[0161] A. In view of the fact that the actual values of the velocity and temperature on both sides of the glass ribbon in the glass tin bath may be inconsistent: since the boundary conditions set in the simulation of Embodiment 1 are generally set in a manner symmetrical to the center line of the tin bath, the simulation results The data and image display are symmetrical, but the actual situation is: the speed of the glass ribbon on the side with high temperature is relatively fast, and the speed of the g...

Embodiment 3

[0167] Example Three: Application of the Mathematical Model of the Glass Tin Bath

[0168] This embodiment utilizes the mathematical model of the glass tin bath that has been established and verified. When there is a quality problem in the glass plate produced by the existing glass tin bath or a problem occurs in the glass process, the calculation of the mathematical model can be used to quickly find the problem. Reduce the maintenance cost and difficulty of the glass tin bath.

[0169] Existing glass tin bath and production overview:

[0170] Glass type: medium aluminum glass (the mass content of alumina in glass is generally between 4% and 8%);

[0171] Production capacity: 150t / d;

[0172] Tin bath parameters: the wide section is 24m x 5.2m (length x width), the length of the shrinkage section is 3m, and the width changes linearly, and the narrow section is 10.8m x 4.5m;

[0173] Protective gas composition: Nitrogen: 92%, Hydrogen: 8%;

[0174] Taking the above-mentione...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com