Electrochemical matching rapid evaluation method

An evaluation method and electrochemical technology, which is applied in the field of lithium-ion batteries, can solve the problems of high research costs, inability to reflect the real characteristics of materials, and long evaluation and testing cycles of pouch batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

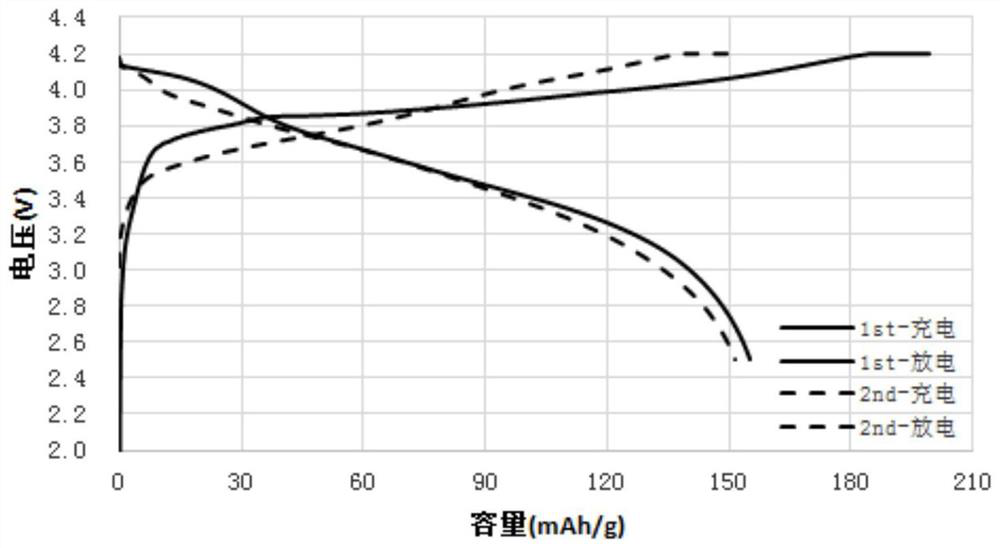

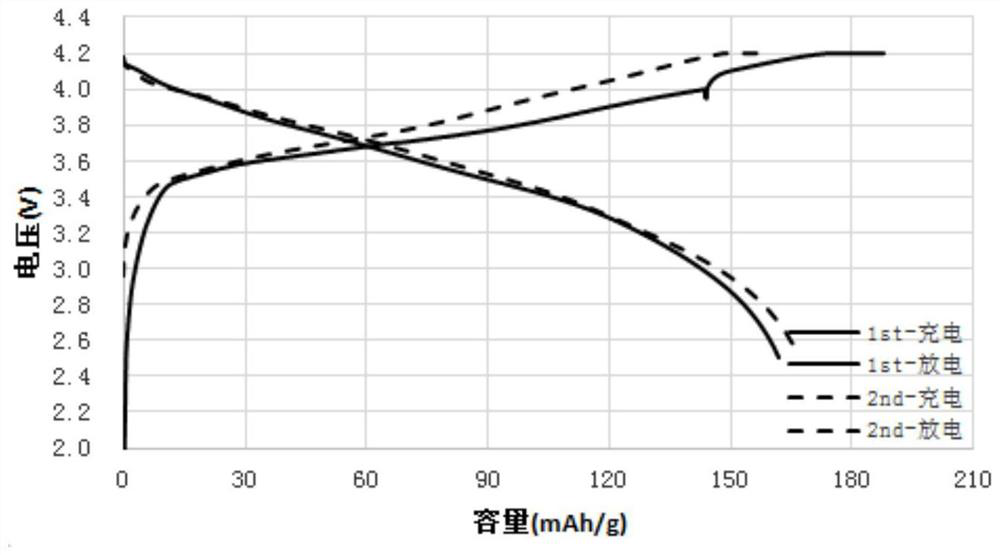

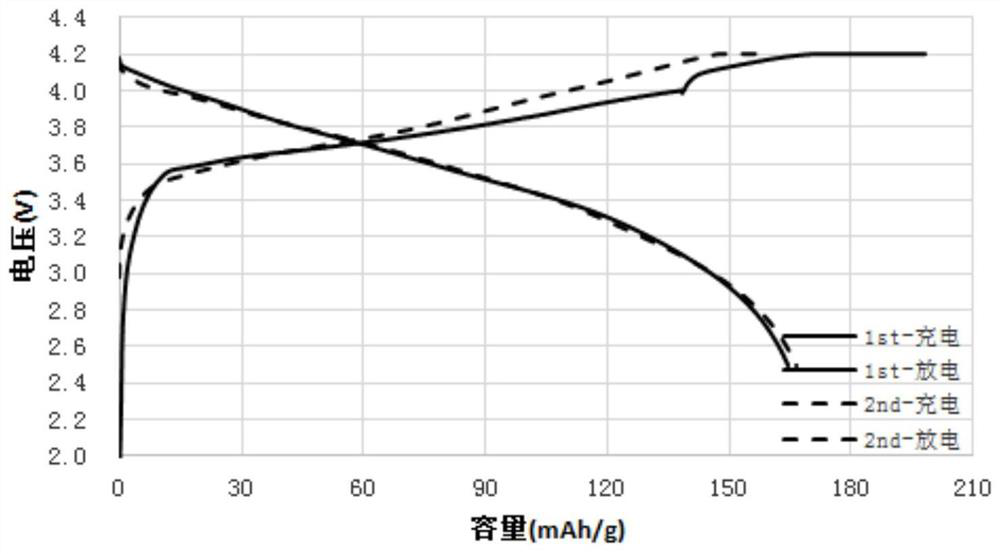

[0043] Example 1: Test using a single-chip full battery

[0044] A method for rapid evaluation of electrochemical matching, comprising the steps of:

[0045] (1) Coating: Coating the prepared positive electrode slurry on 13 μm aluminum foil to make a positive electrode sheet, the thickness of the positive electrode sheet is 115 μm; coating the prepared negative electrode slurry on a 6 μm copper foil to make a negative electrode sheet, The thickness of the negative electrode sheet is 107 μm; the positive electrode sheet and the negative electrode sheet are dried for later use;

[0046] (2) Sheet production: Punch the positive electrode sheet and the negative electrode sheet into fixed sizes respectively. The size of the punched positive electrode sheet is 42mm×49.5mm, and the size of the punched negative electrode sheet is 43.5mm×51mm. The ears are respectively welded on the positive and negative plates;

[0047] (3) Lamination and packaging: Laminate the positive electrode she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com