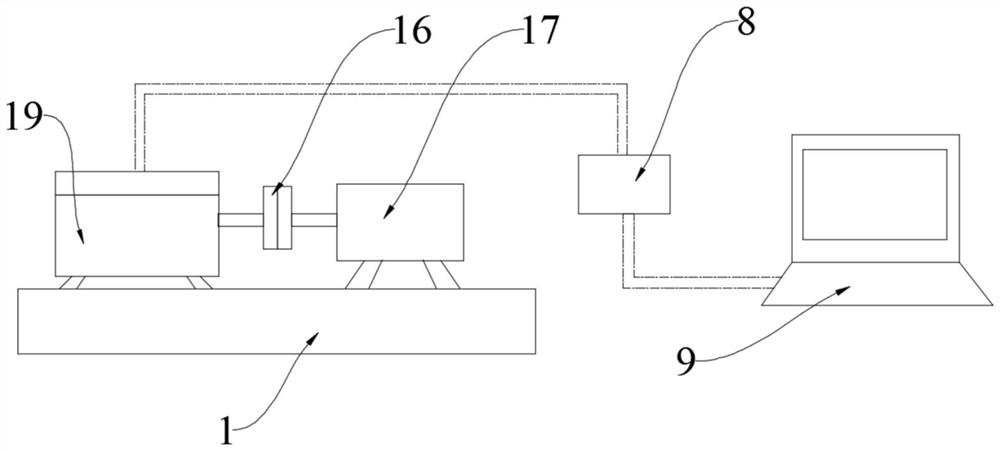

Diesel engine real machine test platform and method for cylinder sleeve-piston ring comprehensive performance analysis

A technology of comprehensive performance and test platform, applied in the direction of internal combustion engine testing, etc., can solve the problems of inability to dynamically simulate the changes of electronically controlled diesel engine operating conditions, failure to realize comprehensive performance detection of diesel engine, low reliability of test results, etc., so as to avoid the failure of test results. , easy to popularize and popularize, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

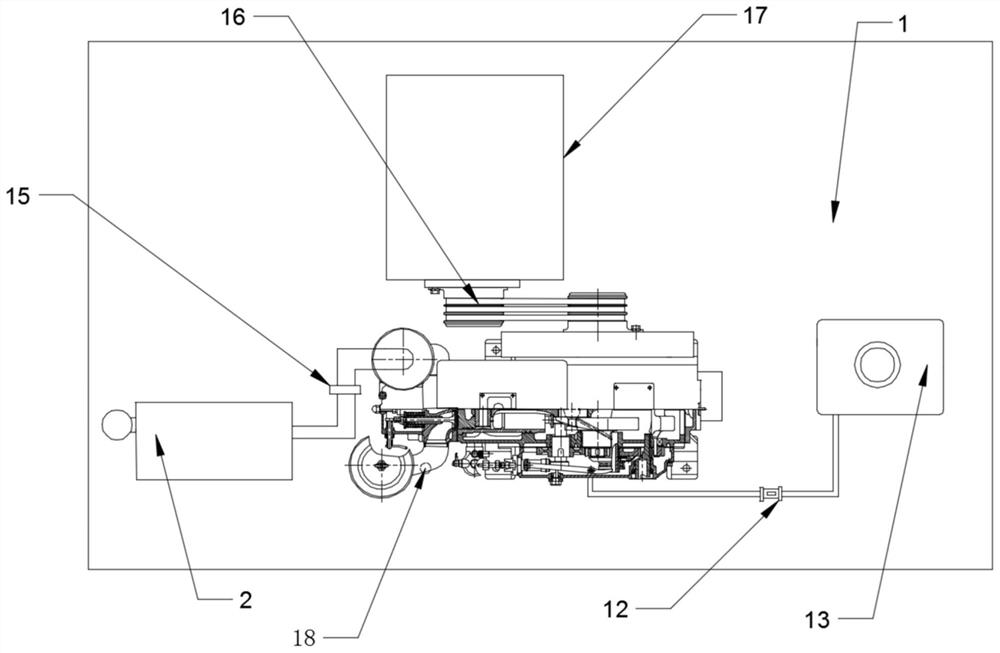

[0041] Specific examples of various types of sensors are as follows: Install various types of sensors:

[0042] Exhaust gas analyzer 2 is used to detect the emission value (gas content) of CO, oxygen, hydrocarbons, carbon dioxide, NO, etc. in the exhaust gas. It is installed near the engine exhaust pipe and connected to the engine exhaust pipe through the pipeline;

[0043] The pressure sensor 4 uses a diffused silicon pressure core as a sensitive element, and a built-in processing circuit outputs a standard voltage signal, and is installed by drilling a small hole on the top of the cylinder head;

[0044] The vibration acceleration sensor 5 uses piezoelectric ceramic crystals as sensitive components, and has a built-in charge amplifier to convert the acceleration into a voltage output to measure the vibration of the engine when it is running. It is installed on the outside of the diesel engine body by magnetic attraction;

[0045] The water temperature sensor 6, a thermistor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com