Construction method for superimposing and connecting wallboards in steel bar lap joint area

A technology of lap connection and wall panel, applied in the direction of walls, structural elements, building components, etc., can solve the problems of high technical requirements, difficulty, and complex construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

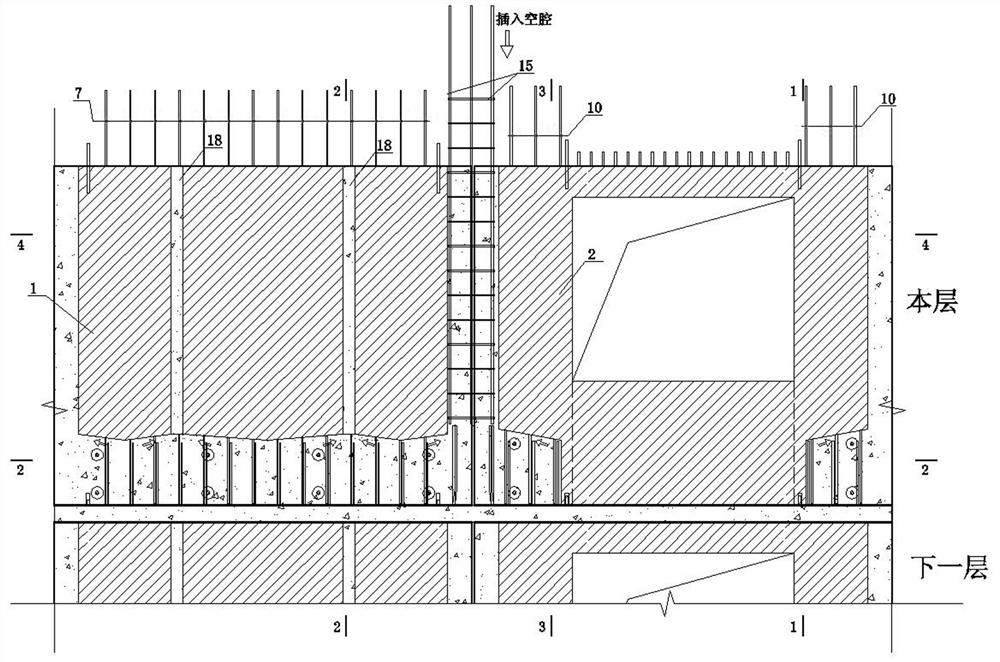

[0030] see Figure 1 to Figure 6 , a construction method for superimposing and connecting wallboards in the overlapping connection area of steel bars is carried out according to the following steps:

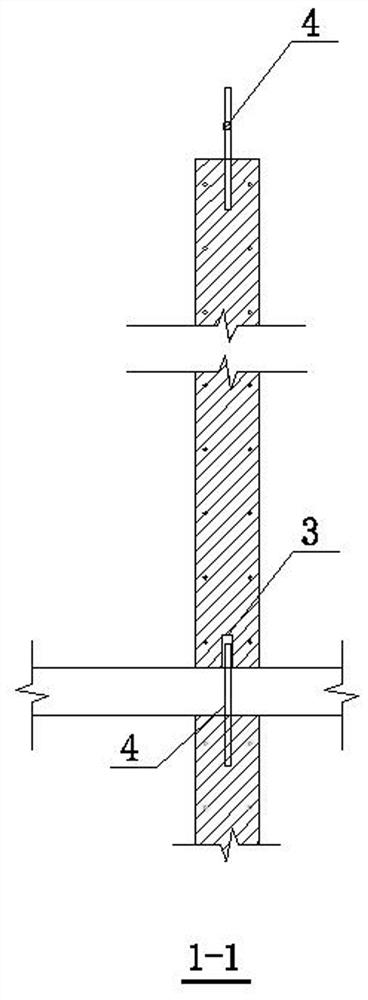

[0031] (1) When installing wall panel 1 without door and window openings and wall panel components 2 with door and window openings on this floor, match the two positioning holes 3 reserved at the bottom of the components with the two positioning steel bars 4 embedded in the lower layer one by one, and then drop and install them.

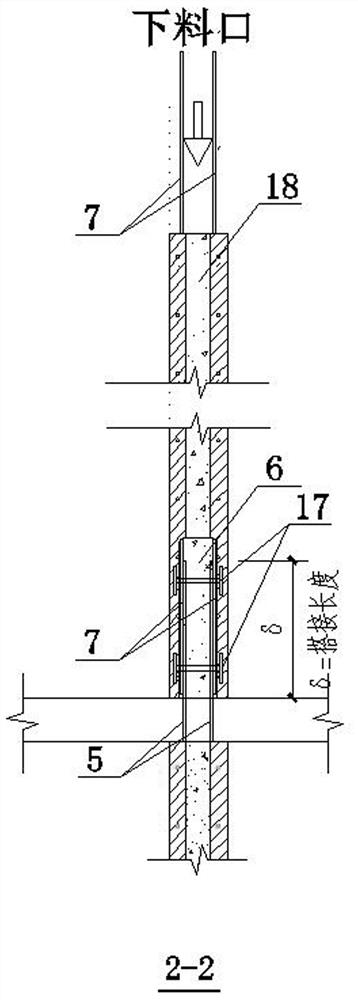

[0032] (2) In the wall panel member 1 without door and window openings, the vertically distributed steel bars 5 of the next layer of wall panels extend into the distributed overlapping cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com