A kind of sealing method of substrate surface pore after oxidation

A substrate surface, pore technology, applied in anodizing, surface reaction electrolytic coating, coating and other directions, can solve the problems of high current density, accelerated corrosion of substrate metal, etc., to achieve good non-stick performance, excellent wear resistance and The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

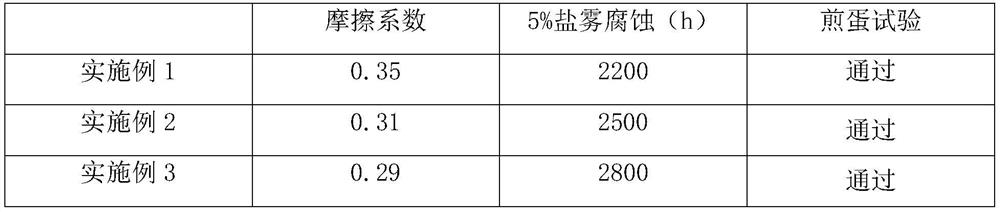

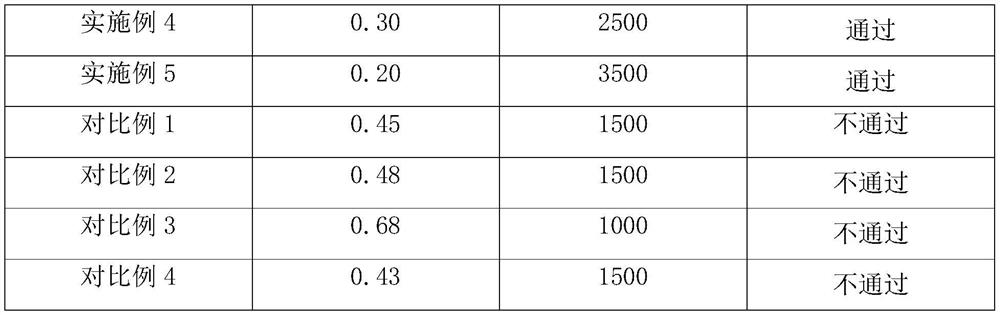

Embodiment 1

[0052] A method for sealing pores on the surface of a substrate after oxidation, the specific steps are as follows:

[0053] (1) Use boiling water to seal the hole for the first time;

[0054] (2) Seal the holes for the second time after diluting with a sealing agent;

[0055](3) Passivation treatment is then performed, and the hole is sealed for the third time after being diluted with a sealing agent;

[0056] (4) Finally, use water vapor to seal the hole for the fourth time;

[0057] Among them, the sealing agent is diluted with a diluent to a mass concentration of 5%, and the sealing system formed by the sealing agent and the diluent is:

[0058] a. Water-based dispersant of polytetrafluoroethylene.

[0059] The specific method for the second sealing in step (2) or the third sealing in step (3) is: spray the sealing system onto the oxide film on the surface of the oxidized substrate, and then perform high-temperature sintering to make the sealing The material in the age...

Embodiment 2

[0069] A method for sealing pores on the surface of a substrate after oxidation, the specific steps are as follows:

[0070] (1) Use boiling water to seal the hole for the first time;

[0071] (2) Seal the holes for the second time after diluting with a sealing agent;

[0072] (3) Passivation treatment is then performed, and the hole is sealed for the third time after being diluted with a sealing agent;

[0073] (4) Finally, use water vapor to seal the hole for the fourth time;

[0074] Among them, the sealing agent is diluted with a diluent to a mass concentration of 80%, and the sealing system formed by the sealing agent and the diluent is:

[0075] b. Oily system of dimethylsiloxane.

[0076] The specific method for the second sealing in step (2) or the third sealing in step (3) is: spray the sealing system onto the oxide film on the surface of the oxidized substrate, and then perform high-temperature sintering to make the sealing The material in the agent is completely...

Embodiment 3

[0087] A method for sealing pores on the surface of a substrate after oxidation, the specific steps are as follows:

[0088] (1) Use boiling water to seal the hole for the first time;

[0089] (2) Seal the holes for the second time after diluting with a sealing agent;

[0090] (3) Passivation treatment is then performed, and the hole is sealed for the third time after being diluted with a sealing agent;

[0091] (4) Finally, use water vapor to seal the hole for the fourth time;

[0092] Among them, the sealing agent is diluted with a diluent to a mass concentration of 5%, and the sealing system formed by the sealing agent and the diluent is:

[0093] c. Silica film, with water as dispersion.

[0094] The specific method for the second sealing in step (2) or the third sealing in step (3) is: spray the sealing system onto the oxide film on the surface of the oxidized substrate, and then perform high-temperature sintering to make the sealing The material in the agent is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com