Method for preparing three-primary-color up-conversion luminescent material with orthogonal excitation-emission response

A technology of luminescent materials and three primary colors, applied in the direction of luminescent materials, nanotechnology for materials and surface science, chemical instruments and methods, etc., can solve the problems of not preparing three primary colors up-conversion luminescent materials, harmful energy transfer, light excitation Crosstalk and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

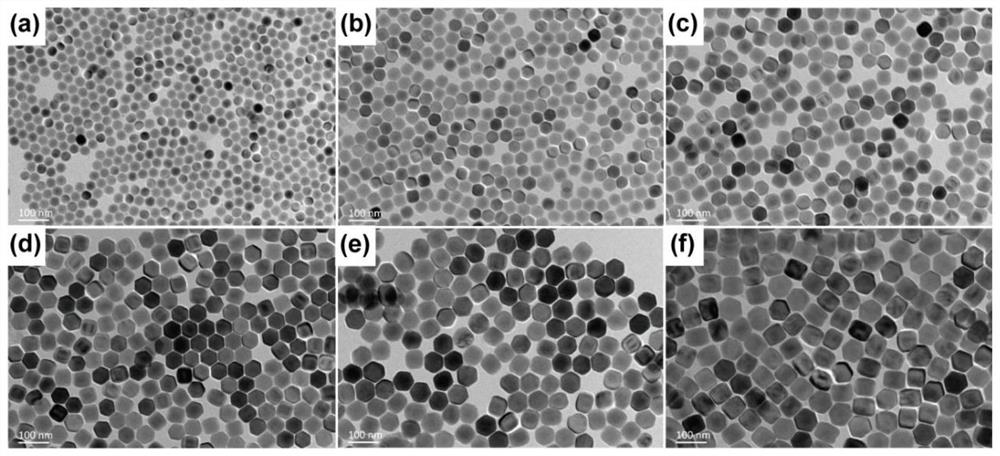

[0053] Example 1: NaYF 4 : Preparation of Yb / Tm (30 / 0.5mol%) core nanocrystals.

[0054] NaYF was first prepared by using a fully automatic nanomaterial synthesizer 4 : Yb / Tm (30 / 0.5mol%) core nanocrystals.

[0055] Specific preparation process: Y(CH 3 COO) 3 (0.278mmol), Yb(CH 3 COO) 3 (0.120mmol) and Tm(CH 3 COO) 3 (0.002mmol) aqueous solution was added to a mixed solvent of 3mL oleic acid and 7mL octadecene at room temperature, stirred and heated to 150°C and reacted for 60 minutes to form the oleic acid complex Y, Yb, Tm-OA core precursor. After the resulting mixed solution was naturally cooled to room temperature, 4 mL of NH 4 F (0.4moL / L) and 2mL NaOH (0.5moL / L) in methanol solution, heated to 50°C and stirred continuously for 30 minutes, then stirred and heated to 100°C, reacted under vacuum for 10 minutes to remove methanol, and finally in an argon atmosphere Lower the temperature to 290°C for 90 minutes. After the reaction was completed, it was cooled to roo...

Embodiment 2

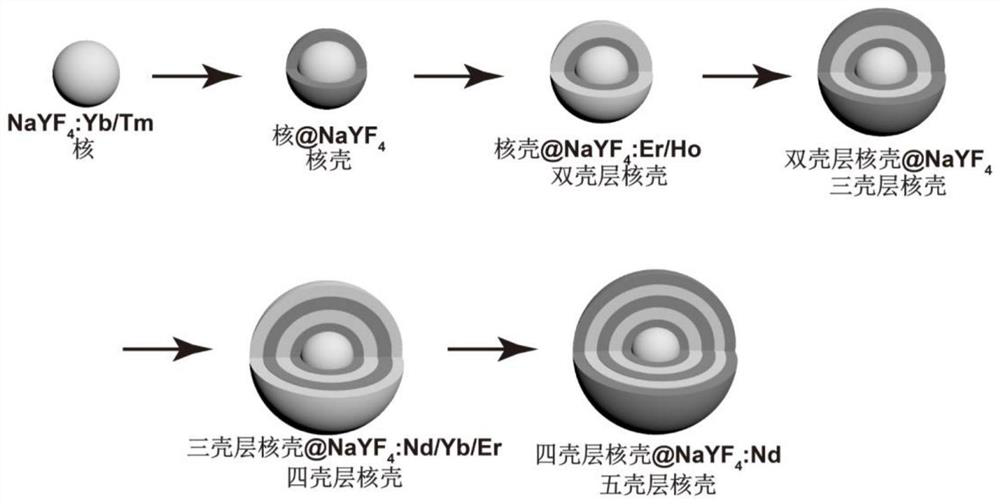

[0056] Example 2: NaYF 4 :Yb / Tm@NaYF 4 Preparation of core-shell nanocrystals.

[0057] The core prepared in Example 1 was used as a seed crystal, and added to the reaction system of the Y-OA shell precursor to induce epitaxial growth of NaYF 4 Shell.

[0058] The specific preparation process is to Y(CH 3 COO) 3 (0.4mmol) aqueous solution is added in the mixed solvent of 3mL oleic acid and 7mL octadecene, the gained mixture is stirred and heated to 150 ℃ and reacted for 60 minutes to form the oleic acid complex Y-OA shell layer precursor, treat that the mixed solution of gained is naturally cooled to After room temperature, the cyclohexane solution (~0.4 mmol) of the core nanocrystals prepared above and 4 mL of NH 4 F (0.4moL / L) and 2mL NaOH (0.5moL / L) methanol solution, continue to stir for 30 minutes under the reaction conditions of 50 ℃, then stir and heat to 100 ℃ for 20 minutes under vacuum to remove cyclohexane and Methanol, finally heated up to 290°C for 90 minute...

Embodiment 3

[0059] Example 3: NaYF 4 :Yb / Tm@NaYF 4 @NaYF 4 : Preparation of Er / Ho (5 / 5mol%) bilayer core-shell structure nanocrystals.

[0060] A fully automatic nanomaterial synthesizer was used to prepare double-layer core-shell structure nanocrystals by layer-by-layer wrapping.

[0061] The specific preparation process is that the preparation of the double-layer core-shell structure nanocrystal is similar to the above-mentioned preparation method of the core-shell structure nanocrystal. It is only necessary to replace the Y-OA shell precursor prepared above with the Y, Er, Ho-OA shell precursor, and use the core-shell structure nanocrystal prepared in Example 2 as a seed crystal to induce epitaxial growth of NaYF 4 : Er / Ho shell. The prepared product was dispersed into cyclohexane for characterization and preparation of three-layer core-shell structure nanocrystals in the next step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com