Dry-mixed thermal insulation mortar and preparation method and use method thereof

A technology of thermal insulation mortar and dry mixing, applied in the field of materials, can solve the problems of reducing aerogel content, easy dissipation, poor comprehensive thermal insulation performance of aerogel mortar, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

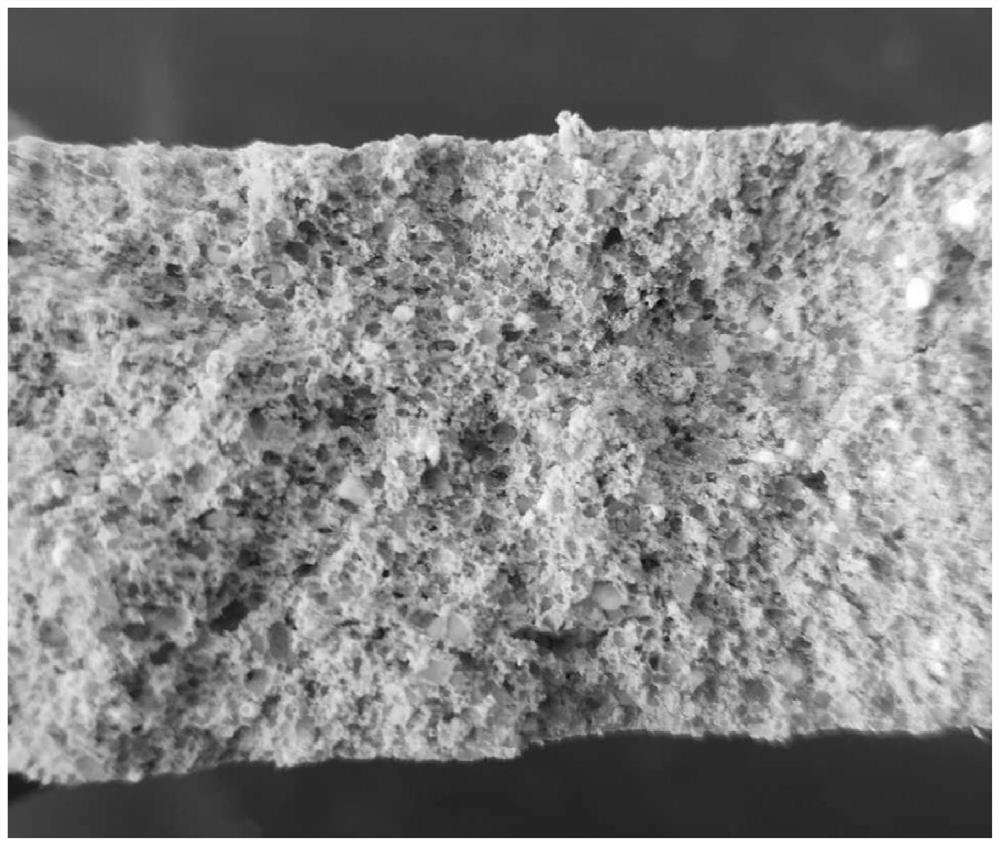

Image

Examples

Embodiment 1

[0056] Preparation of continuously graded airgel particles:

[0057] (1) Ethyl orthosilicate, methyl triethoxysilane, ethanol, and water are mixed according to the molar ratio of 1:0.3:14:5, acid is added to adjust pH=4.5, after hydrolysis for 30 minutes, alkali is added to adjust pH=8.9 , let the gel stand for 2h.

[0058] (2) After the gel obtained in (1) is broken into fragments smaller than 10 cm, it is transferred to a supercritical drying kettle for drying.

[0059] (3) Ethanol supercritical drying process: after ethanol submerges the fragments, pressurize nitrogen to 0.3MPa, heat to 270°C, control the pressure to 16MPa, keep constant temperature and pressure for 2 hours, and then release the pressure to normal pressure at constant temperature, after cooling and discharging That is, airgel fragments are obtained.

[0060] (4) After the airgel fragments obtained in (3) are crushed by a crusher until the particle diameter is not greater than 2mm, sieve, and 30% of the co...

Embodiment 2

[0064] Preparation of continuously graded airgel particles:

[0065] (1) Ethyl orthosilicate, methyl triethoxysilane, ethanol, and water are mixed according to the molar ratio of 1:0.2:16:5, acid is added to adjust pH=4.7, after hydrolysis for 30 minutes, alkali is added to adjust pH=8.5 , let the gel stand for 3h.

[0066] (2) After the gel obtained in (1) is broken into fragments smaller than 10 cm, it is transferred to a supercritical drying kettle for drying.

[0067] (3) Ethanol supercritical drying process: after ethanol submerges the fragments, pressurize nitrogen to 0.3MPa, heat to 270°C, control the pressure to 16MPa, keep constant temperature and pressure for 2 hours, and then release the pressure to normal pressure at constant temperature, after cooling and discharging That is, airgel fragments are obtained.

[0068] (4) After the airgel fragments obtained in (3) are crushed by a crusher until the particle diameter is not greater than 2mm, sieve, and 25% of the co...

Embodiment 3

[0072] A dry-mix thermal insulation mortar, which is similar to Example 1, except that the content of continuously graded airgel composite particles is 7 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com