A kind of elastic non-pneumatic tire and vehicle

A non-pneumatic tire, elastic technology, applied in the direction of non-pneumatic tires, vehicle parts, tire parts, etc., can solve the problems of poor radial and lateral mechanical properties of elastic tires, achieve good mechanical properties, enhance connection, and enhance stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

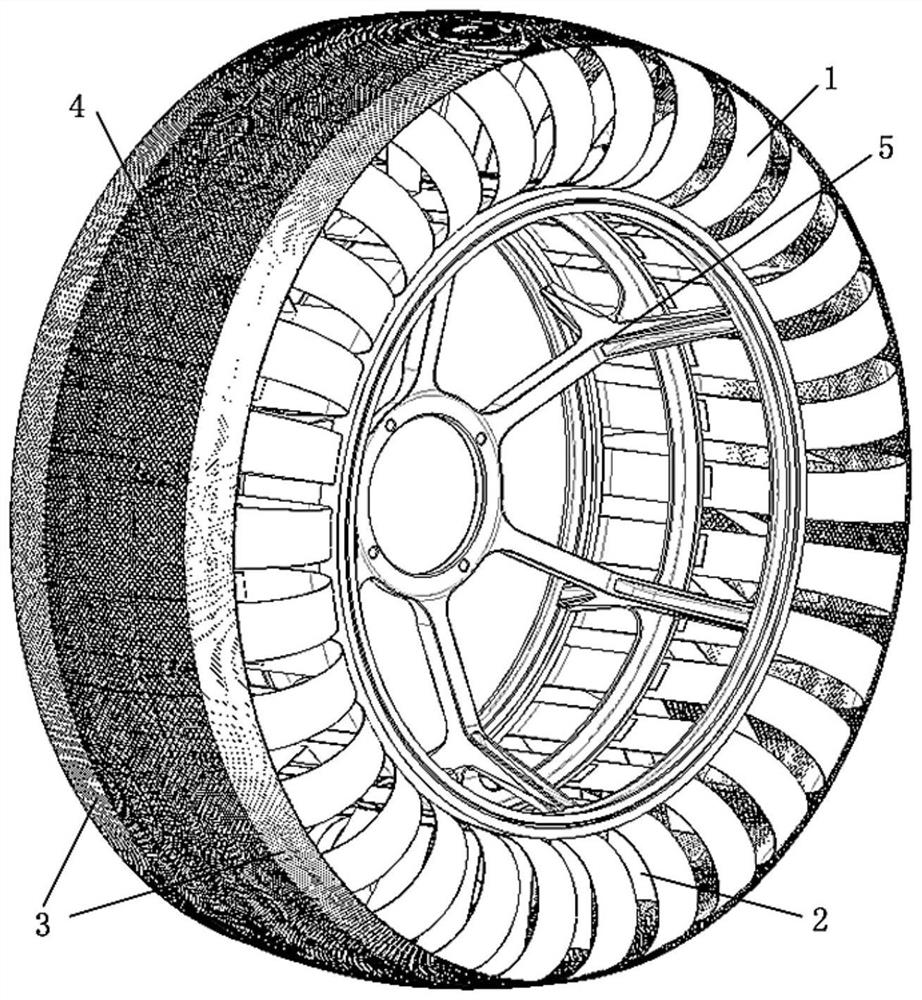

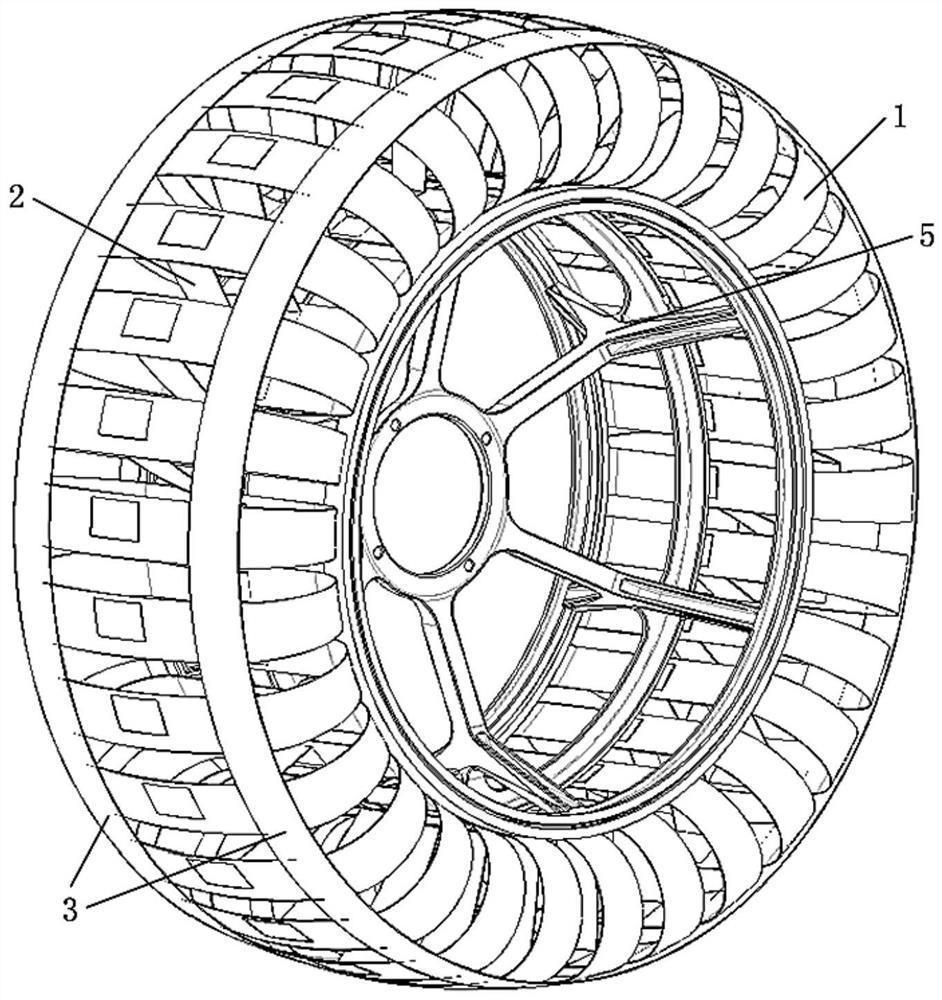

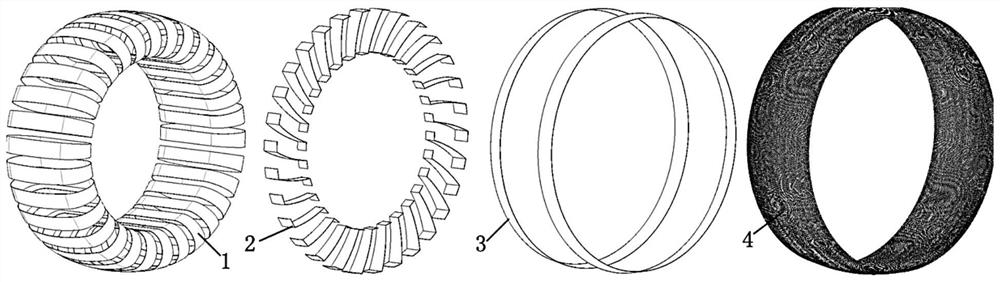

[0031] see Figure 1 to Figure 4 , In one embodiment, an elastic non-pneumatic tire includes a wheel hub 5, an outer bead 4, and a carcass.

[0032] The outer bead 4 is sleeved on the hub 5 and cooperates with the hub 5 to form an annular accommodating space.

[0033] The carcass includes a plurality of carcass components, the carcass components are respectively arranged in the annular accommodating space, and both ends of each carcass component are connected to the outer circumferential surface of the wheel hub 5 and the inner circumferential surface of the outer bead 4 respectively.

[0034] The carcass assembly includes an annular elastic member 1 and a first elastic unit 2 . The first end of the annular elastic member 1 is connected to the inner circumferential surface of the outer bead 4 , the second end is connected to the outer circumferential surface of the wheel hub 5 , and the opening of the annular elastic member 1 faces the circumferential direction of the wheel h...

Embodiment 2

[0044] A vehicle equipped with the elastic non-pneumatic tire in the first embodiment. The elastic non-pneumatic tire is provided with a wheel hub 5, an outer bead 4 and a carcass, and the carcass is arranged between the wheel hub 5 and the outer bead 4; wherein, the carcass specifically includes an annular elastic member 1 and a first elastic unit 2. The annular elastic member 1 is arranged between the hub 5 and the outer bead 4, and the first elastic unit 2 is arranged in the inner ring of the annular elastic member 1 to support the annular elastic member 1. The annular elastic member 1 forms the overall external configuration of the tire and is A certain supporting force is provided at the shoulder part, the annular configuration ensures the radial and lateral mechanical properties of the tire, the first elastic unit 2 supports the tread to improve the radial rigidity of the tire, the annular elastic member 1 and the first elastic unit 2 The elastic characteristics of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com