PCB defect data generation method based on deep learning

A data generation and deep learning technology, applied in image data processing, biological neural network model, image enhancement and other directions, can solve the problem of skewed sample quantity and model overfitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

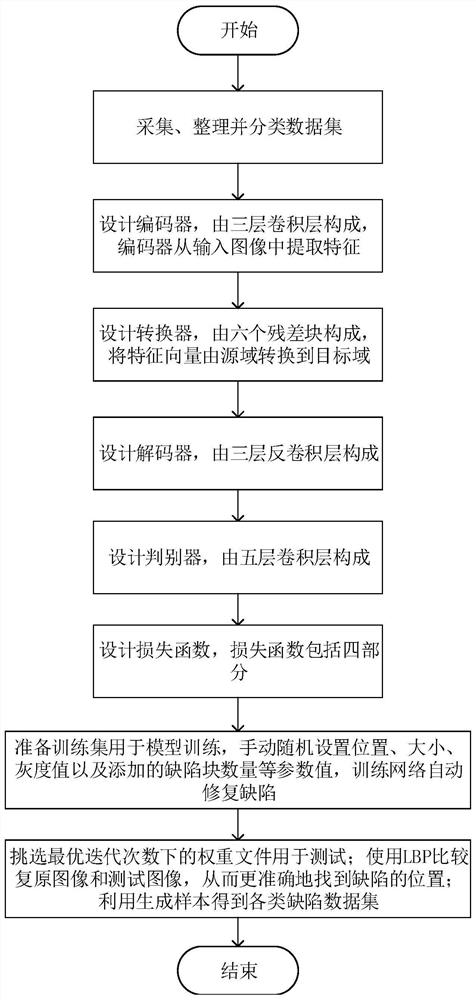

[0057] Such as Figure 1 to Figure 9 As shown, this embodiment discloses a method for generating PCB defect data based on deep learning in factory PCB defect detection, including the following specific implementation steps:

[0058] 1) Collect image data sets of non-defective PCB boards in the factory, and organize the data sets.

[0059] 2) Construct a generative adversarial network model to solve the problem of category-sample imbalance. The envisaged method is unsupervised image-to-image translation, inspired by GAN-based repair and detection models, and aims to design a network structure based on two sets of unidirectional GANs that can achieve bidirectional image generation. Since there are many types of defects, and each model can only be used to generate a specific type, it is necessary to perform category migration and use the model to generate defect data sets of all types.

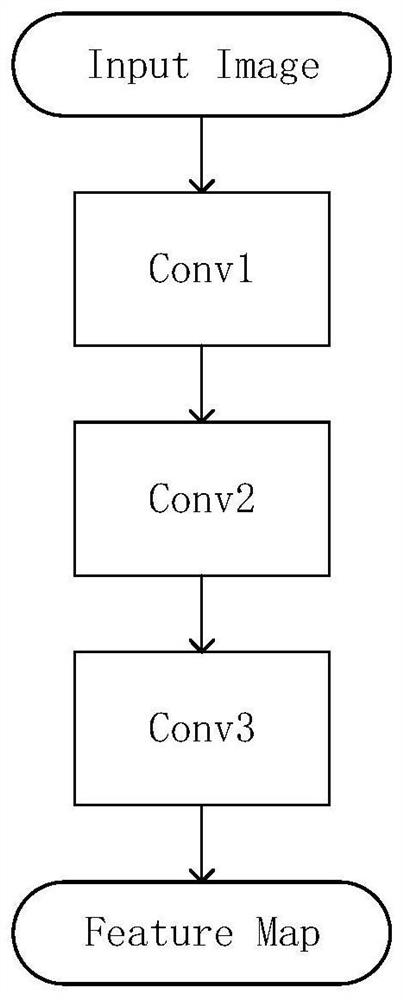

[0060] 3) The model is divided into generator and discriminator. Firstly, the generator mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com