Common-optical-path phase shift digital holographic microscopic measurement device

A technology of digital holographic microscopy and measuring device, applied in the field of digital holography, can solve the problems of complex phase reconstruction of digital holograms, disadvantageous phase reconstruction accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

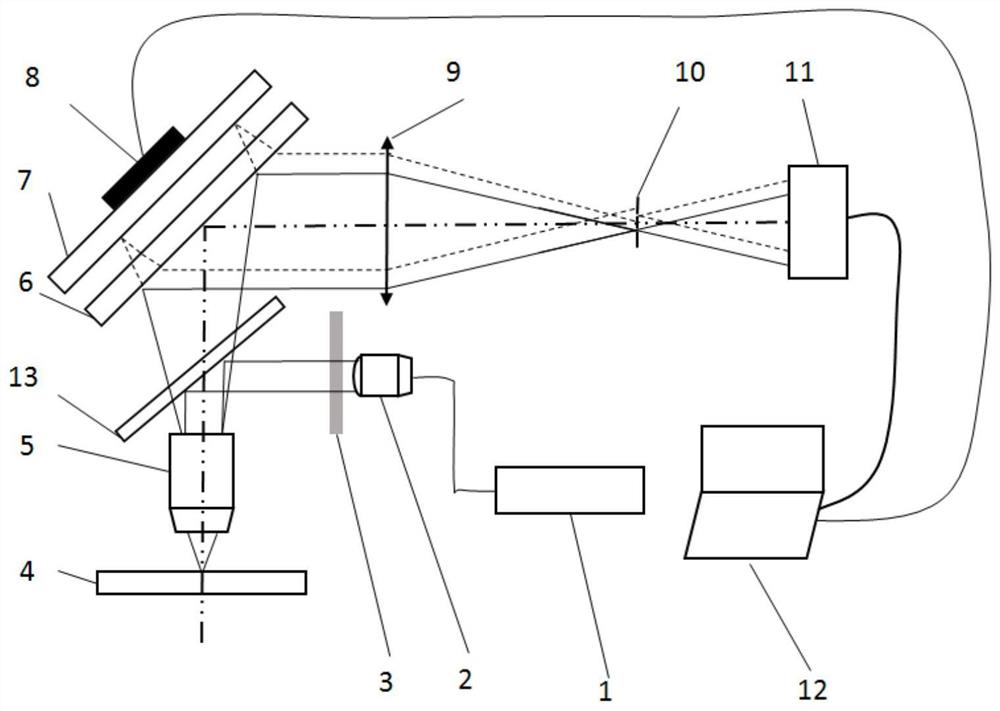

[0022] Such as figure 1 and image 3 As shown, this embodiment provides a common optical path phase-shift digital holographic microscopic measurement device, including a fiber laser 1, a fiber collimator 2, an adjustable attenuator 3, a sample to be tested 4, a microscopic objective lens 5, and a flat flat crystal I 6, plane flat crystal II7, piezoelectric ceramic driver 8, converging lens 9, filter 10, imaging detection device 11 and computer 12. This structure forms a transmission type common light path phase shift digital holographic microscopic measurement device.

[0023] The fiber laser 1 and the fiber collimator 2 are connected with a single-mode fiber to form a parallel beam;

[0024] The parallel beam passes through the adjustable attenuator 3 and directly irradiates the sample 4 to be tested, wherein the adjustable attenuator 3 can adjust the energy of the parallel beam so that the laser energy meets the requirements of the imaging detection device 11;

[0025] Th...

Embodiment 2

[0037] Such as figure 2 and image 3 As shown, on the basis of Embodiment 1, a beam splitter 13 is also arranged between the adjustable attenuator 3 and the microscope objective lens 5 to form a reflective common optical path phase-shift digital holographic microscopic measurement device, wherein the optical fiber The laser 1 and the fiber collimator 2 are connected with a single-mode fiber to form a parallel beam;

[0038] After the parallel beam passes through the adjustable attenuator 3, the beam is reflected by the beam splitter 13 and irradiates the microscopic objective lens 5, wherein the adjustable attenuator 3 can adjust the energy of the parallel beam so that the laser energy meets the imaging detection device 11 requirements;

[0039] The tested sample 4 is located on the focal plane of the microscope objective lens 5, so that the tested sample 4 can be clearly imaged on the imaging detection device 11;

[0040] Planar flat crystal I 6 and flat flat crystal II 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com