Reflective microscopic imaging device based on dual-wavelength digital holographic technology

A digital holography and microscopic imaging technology, which is applied in the fields of imaging and optical measurement, can solve the problems of complex algorithms and large amount of calculation, and achieve the effects of reducing complexity, improving phase reconstruction accuracy, and avoiding the phase unwrapping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

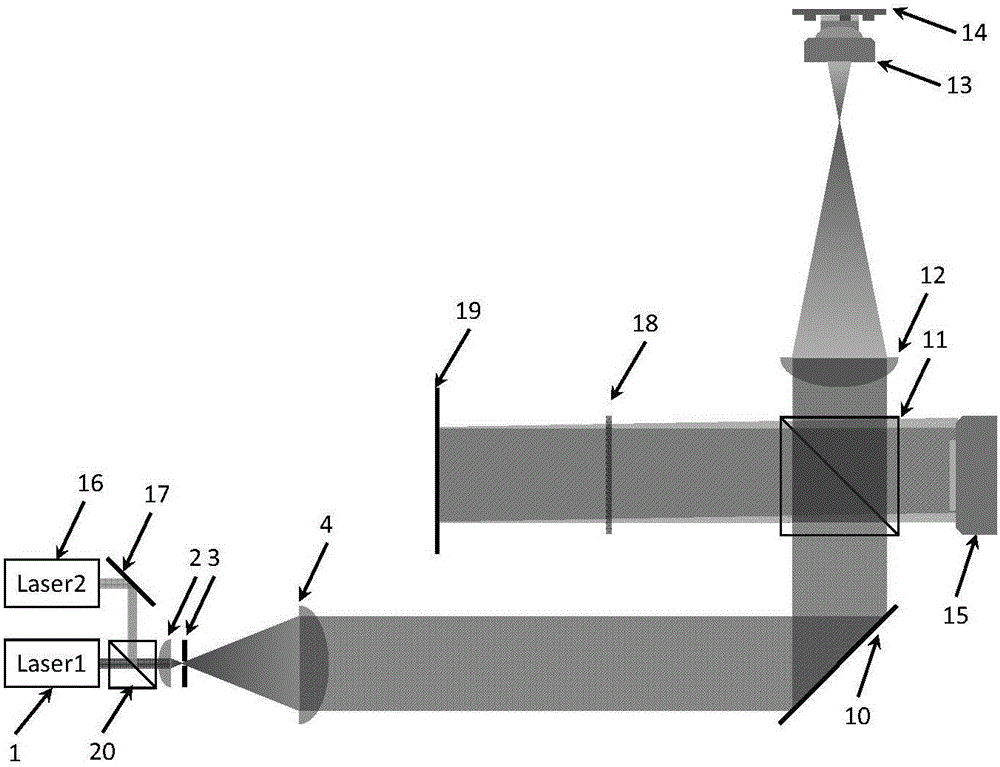

[0010] As shown in Figure 1(a), the reflective microscopic imaging device based on the dual-wavelength digital holography technology of the present invention includes a first laser 1, a second laser 16, a concentrating mirror 2, a concentrating mirror pinhole diaphragm 3, and a concentrating mirror 4 , the first plane mirror 10, the second beam splitter 11, the lens tube lens 12, the microscope objective lens 13, the camera 15, the sixth plane mirror 17, the first attenuation sheet 18 and the second plane mirror 19, the third beam splitter 20, so The condenser pinhole diaphragm 3 described above is placed on the rear focal plane position of the condenser mirror 2, which is also the front focal plane position of the condenser mirror 4; wherein the laser light emitted by the first laser 1 passes through the third beam splitter 20, the condenser mirror 2 converges to the pinhole diaphragm 3 of the condenser mirror, the light diverges through the pinhole diaphragm 3 of the condense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com