Blade type hydraulic flow deceleration sensor and deceleration method

A blade-type, deceleration technology, applied in the field of sensors, can solve the problems of delayed brake start time, ABS start lag, and inability to start ABS in a timely and convenient manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

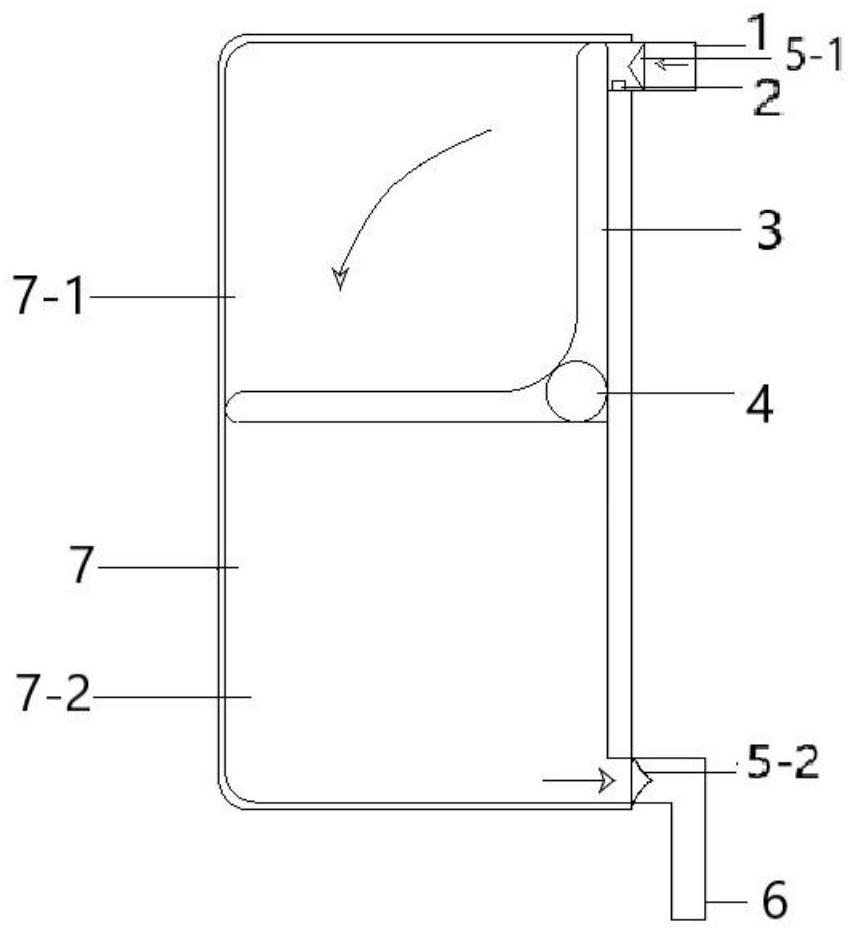

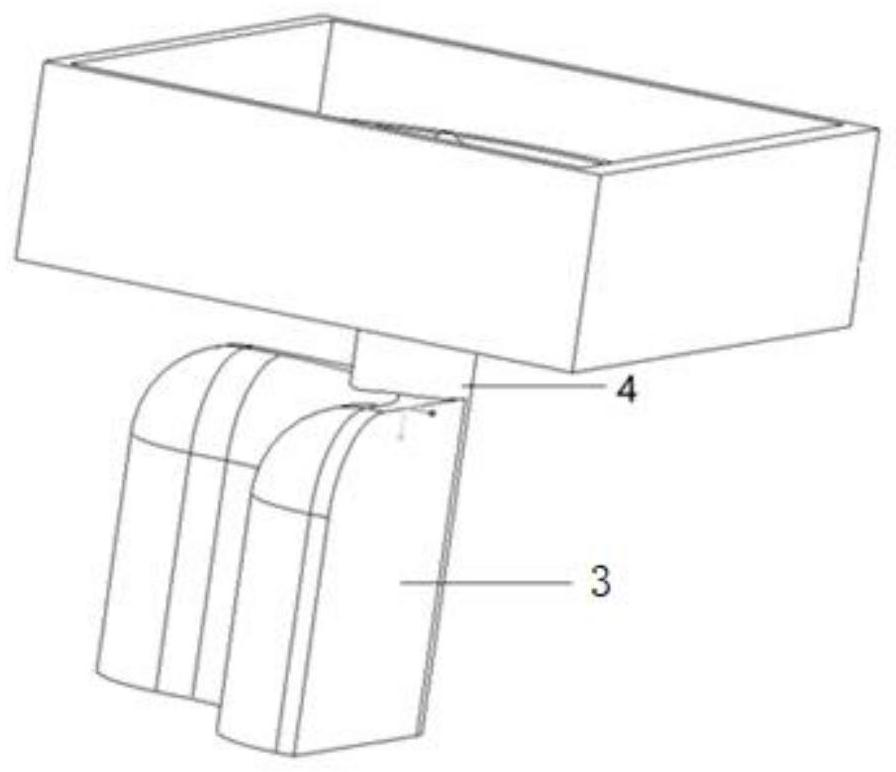

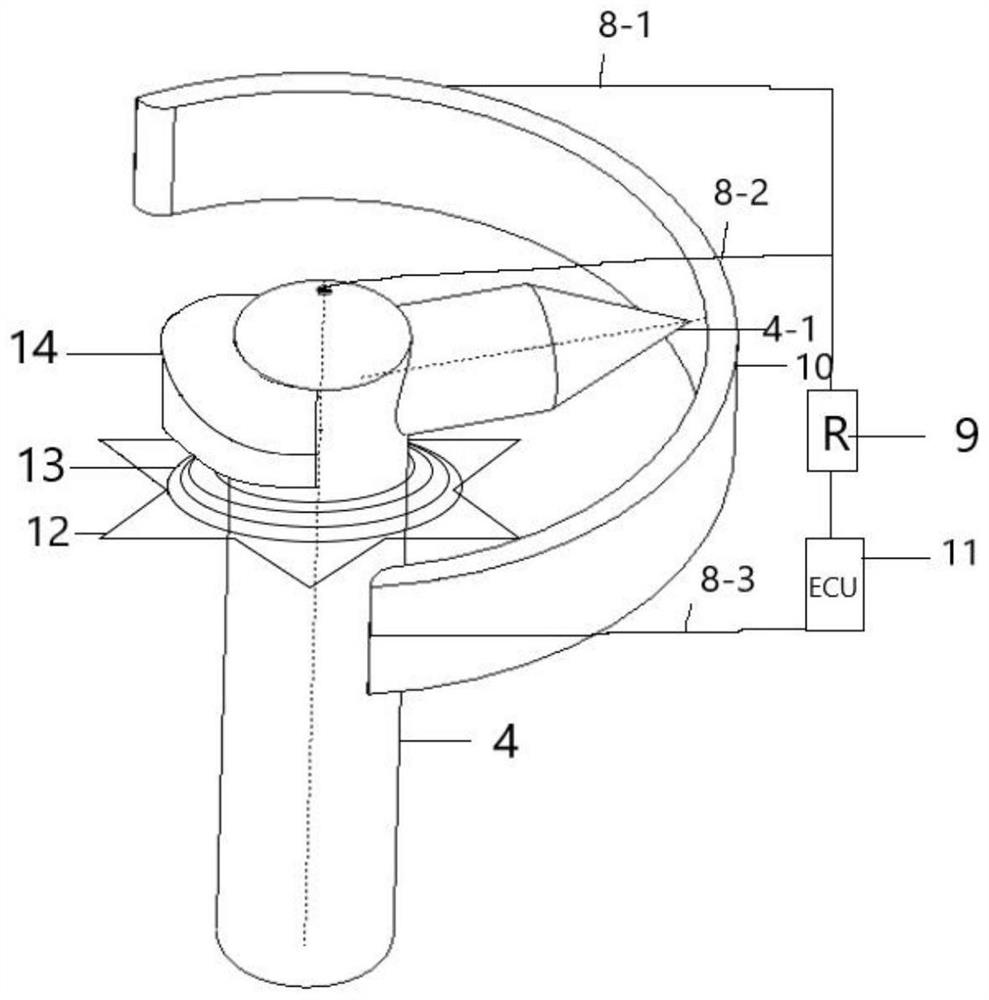

[0022] Such as figure 1 As shown, the vane-type hydraulic flow deceleration sensor of the present invention includes a housing 7, a T-shaped rotating shaft 4 is fixed inside the housing 7, and a vane-type damping plate 3 is installed on the T-shaped rotating shaft 4; the vane-type damping plate 3 is located inside the housing 7 , and rotate under the action of hydraulic oil. A pressure sensor 2 is installed at the joint position between the oil inlet 1 and the housing 7 to detect the rate of change of hydraulic oil pressure. The variable resistor 10 is located in the top of the housing 7, and the variable resistor has an arc structure. The upper end of the rotating shaft is fixed with a balance counterweight 14, and the counterweight and the side top end 4-1 rotate together with the vane type damping plate 3; one end of the return spring 13 is fixed on the T-shaped rotating shaft 4 of the damping plate, and the other end is fixed on the ring gear 12; the T-shaped rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com