Visual shaft sleeve lubrication test device for engineering machinery

A technology for lubrication test equipment and engineering machinery, which is applied in the direction of measuring equipment, material inspection products, instruments, etc., and can solve problems such as poor lubrication, loss, and mechanical grinding sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

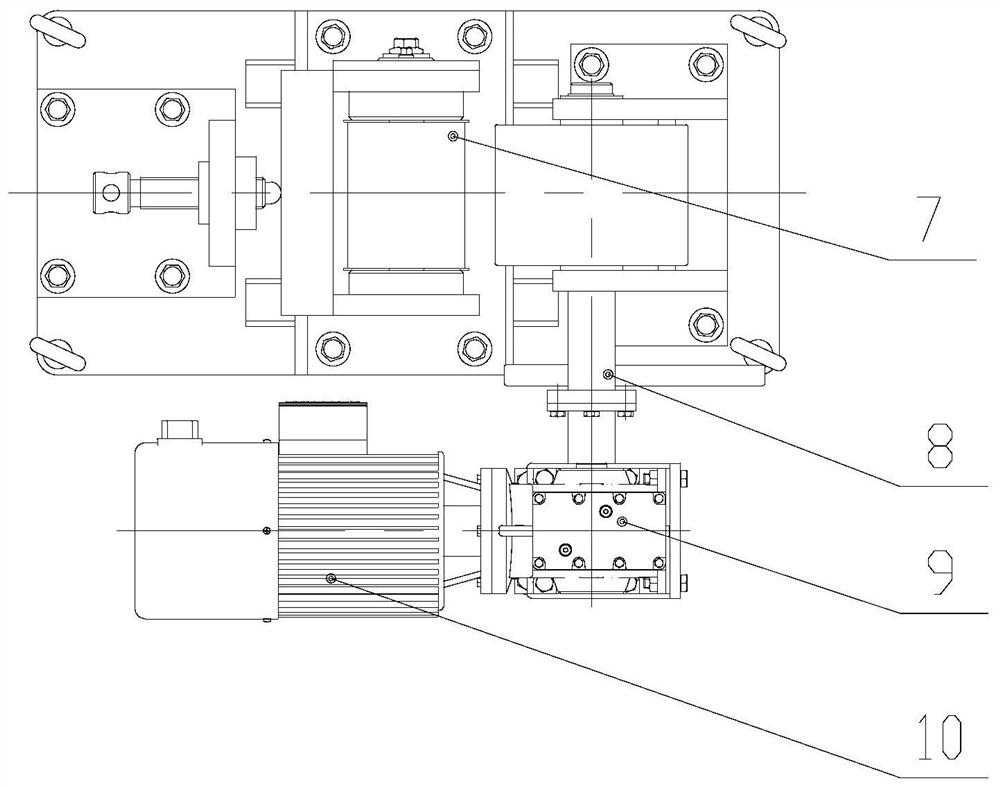

[0024] Such as figure 1 , 2 As shown in , 3, it is a related diagram of a visual bushing lubrication test device for engineering machinery provided by the present invention, which includes a machine base assembly 1, which is provided with a pressure applicator 2, and the machine base assembly 1 and The slide seat 3 is assembled by a linear slide rail, and the slide seat 3 can slide on the slide rail. The shaft seat 4 is assembled on the sliding seat 3 and moves synchronously with the sliding seat 3 as a whole. Sealing elements 11 are installed at both ends of the transparent shaft sleeve 7 . Such as figure 1 , the transparent shaft sleeve 7 is assembled with the hinge pin 5 and the shaft seat 4, and the end side plate of the hinge pin 7 is fixed on the shaft seat 4, and the transparent shaft sleeve 7 can rotate on the hinge pin 5. The machine base assembly 1 is provided with a steel wheel frame, the pressure steel wheel 6 is assembled on the steel wheel frame, the frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com