A method for 3D printing high temperature resistant graphene-based conductive structures

A 3D printing, graphene-based technology, applied in the direction of equipment for manufacturing conductive/semiconductive layers, chemical instruments and methods, circuits, etc., can solve the problem of low solid content, shrinkage deformation, and difficulty in maintaining the design shape and precision of the structure and other problems, to achieve good rheological properties, high printing accuracy, and good shear thinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

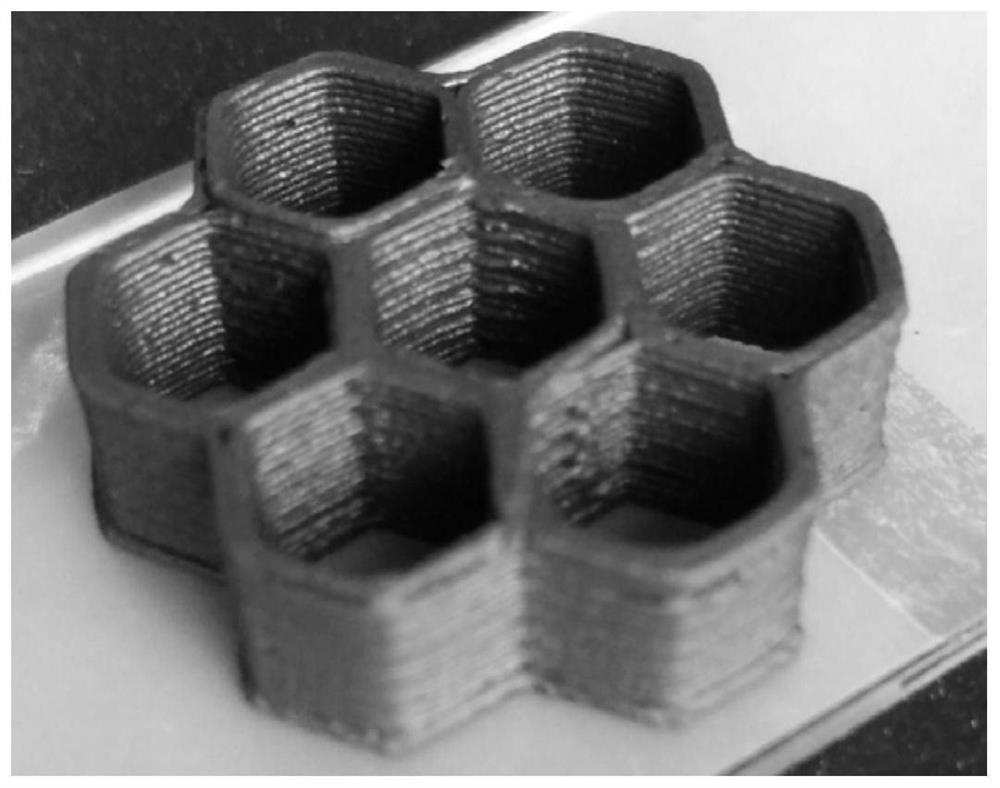

Image

Examples

specific Embodiment approach 1

[0034] Embodiment 1: A method of 3D printing a high-temperature resistant graphene-based conductive structure in this embodiment is carried out according to the following steps:

[0035] 1. Preparation of graphene oxide:

[0036] 1. Mix the concentrated sulfuric acid, potassium persulfate and phosphorus pentoxide with a mass percentage of 30% to 70% and stir evenly, then add graphite, and keep the temperature at 50 ℃ to 90 ℃ for 2h to 4.5h. Then add deionized water and let stand for 5h~24h to obtain a standing liquid;

[0037] The quality of described potassium persulfate and mass percent are that the volume ratio of the vitriol oil of 30%~70% is 1g:(3~5)mL; The mass ratio of described potassium persulfate and phosphorus pentoxide is 1: (0.8~1.2); The mass ratio of described potassium persulfate and graphite is 1:(1~1.2); The mass ratio of described potassium persulfate and deionized water is 1g:(10~100)mL ;

[0038] 2. Pour off the supernatant of the standing solution, fil...

specific Embodiment approach 2

[0055] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the graphite described in step 1 ① is high-purity flake graphite, and the particle size is 50 meshes to 1000 meshes. Others are the same as the first embodiment.

specific Embodiment approach 3

[0056] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the molecular weight cut-off of the dialysis bag described in step 1 (4) is 14,000. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com