High-capacity embedded conical-surface synchronizer and transmission

An embedded and synchronizer technology, applied in the direction of clutches, friction clutches, mechanically driven clutches, etc., can solve difficulties, increase gear bending fatigue and contact fatigue life and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

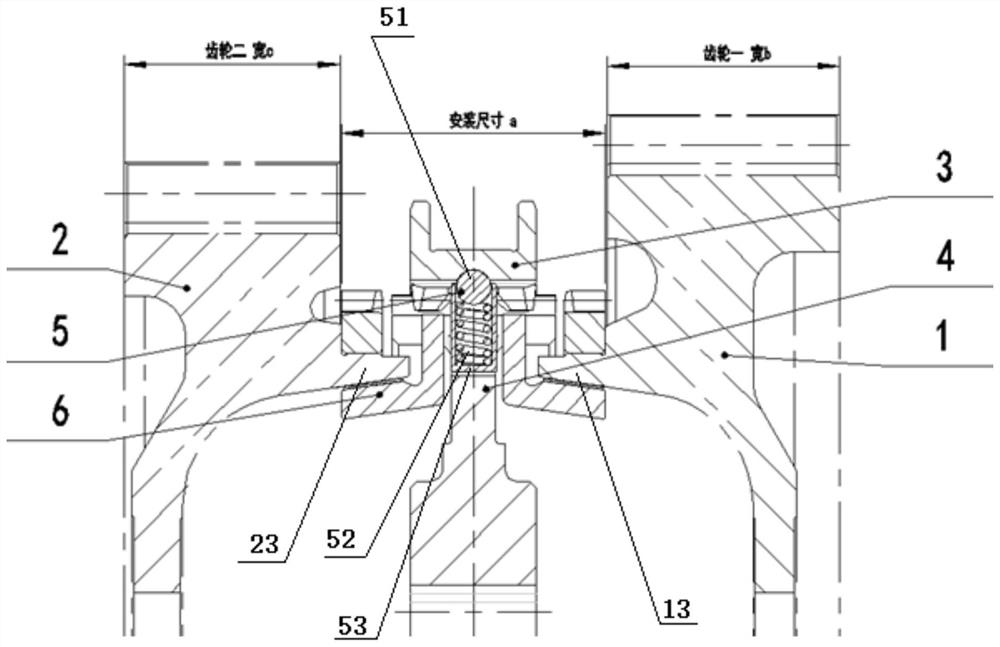

[0099] Such as figure 1 As shown, the synchronizer of this embodiment is an embedded single-cone synchronizer, which is arranged between the first gear assembly 1 and the second gear assembly 2. The first gear assembly 1 is composed of the first gear 11 and the first gear assembly. The second gear assembly 2 is composed of the second gear 21 and the second combined ring gear 22 .

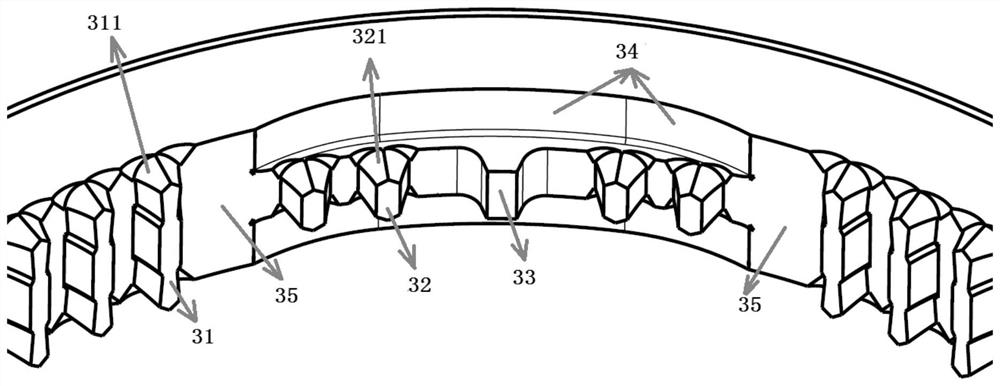

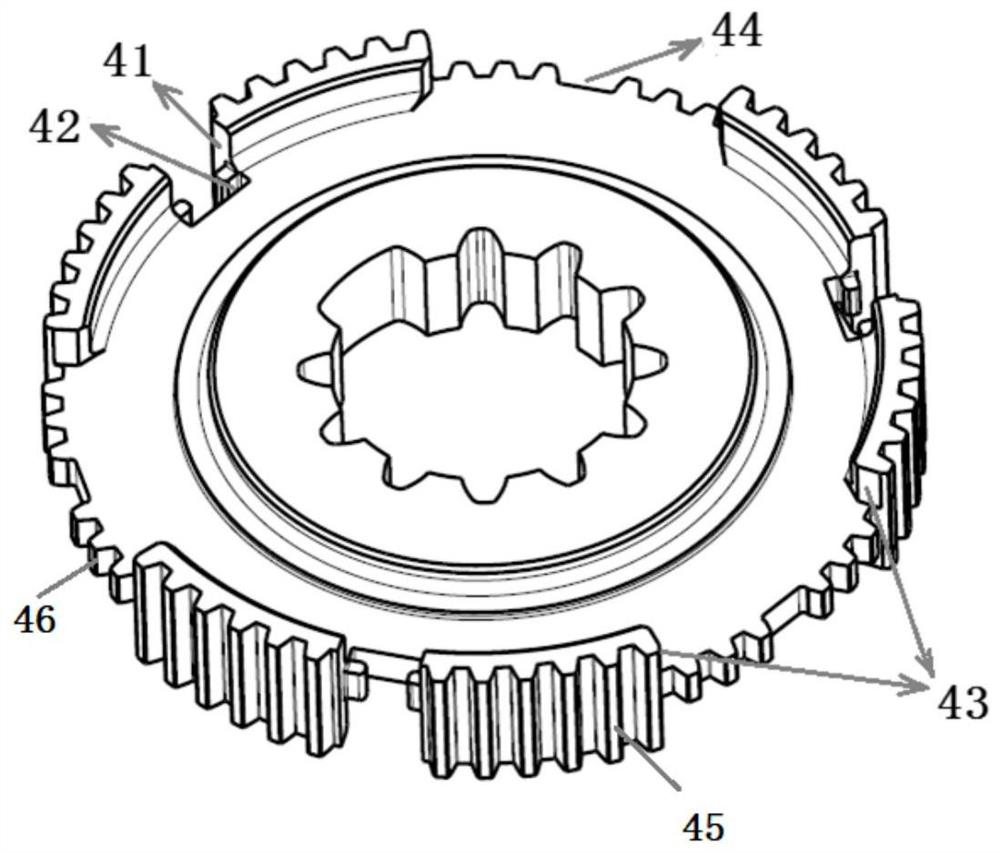

[0100]The embedded single-cone synchronizer includes a gear hub 4, a sliding gear sleeve 3, a steel ball spring packaged slider body 5 and a pair of locking rings 6; the sliding gear sleeve 3 is set on the outer circumference of the gear hub 4, And can axially slide relative to the gear hub 4; the steel ball spring packaged slider body 5 is arranged between the sliding gear sleeve 3 and the gear hub 4, and is located in the radial groove 42 of the gear hub 4 (such as Figure 4 ); a pair of locking rings 6 are respectively nested at both ends of the gear hub 4 .

[0101] In order to reduce the ins...

Embodiment 2

[0111] Such as Figure 9 As shown, the synchronizer of this embodiment is an embedded double-cone synchronizer, which is arranged between the first gear assembly 1 and the second gear assembly 2. The first gear assembly 1 is composed of the first gear 11 and the first gear assembly. The second gear assembly 2 is composed of the second gear 21 and the second combined ring gear 22 .

[0112] The embedded double-cone synchronizer includes gear hub 4, sliding gear sleeve 3, steel ball spring packaged slider body 5, a pair of locking rings 6, a pair of first friction rings 7 and a pair of second friction rings 8 ; The sliding gear sleeve 3 is set on the outer circumference of the gear hub 4, and can slide axially relative to the gear hub 4; the steel ball spring packaged slider body 5 is arranged between the sliding gear sleeve 1 and the gear hub 2, and Located in the radial groove of the gear hub 2; a pair of locking rings 6 are respectively nested at both ends of the gear hub 2;...

Embodiment 3

[0123] Such as Figure 15 As shown, the synchronizer of this embodiment is an embedded three-cone synchronizer. On the basis of the solution of Embodiment 1, a pair of first friction rings 7 and a pair of The second friction ring 8, at the same time in order to make the first friction ring 7 and the locking ring 6 can rotate synchronously, the corresponding structure of the locking ring 6 has been adjusted; Conical surface forms the first friction pair with the inner conical surface of the first annular boss 13 and the second annular boss 23 respectively, the inner conical surface of a pair of first friction rings 7 and the outer outer surface of a pair of second friction rings 8 respectively. The tapered surfaces form the second friction pair, and the inner tapered surfaces of a pair of second friction rings 8 respectively form the third friction pair with the outer tapered surfaces of a pair of locking rings 6; during the synchronization process, the first friction pair, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com