Cloth drying device for textile products processing

A technology for fabric drying and supplies, applied in textiles and papermaking, drying, spraying/jetting textile material processing, etc., can solve problems such as high temperature damage to the surface of fabrics, and achieve improved safety, effect, stability and safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

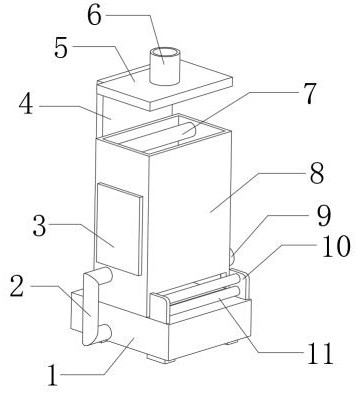

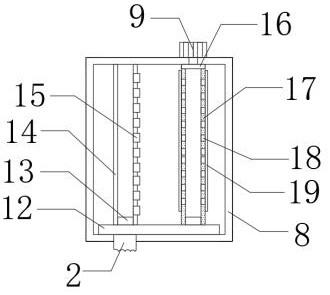

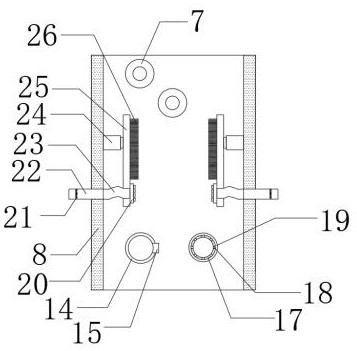

[0028] refer to Figure 1-4 , a cloth drying device for processing textile products, comprising a drying box 8, the bottom outer wall of the drying box 8 is connected with a water storage box 1 by bolts, and the bottom outer wall of one end of the water storage box 1 is connected by bolts There is a water guide pipe 2, the outer wall of one side of the water guide pipe 2 is connected with a water pump by bolts, the inner wall of the bottom of one side of the drying box 8 is connected with a water distribution pipe 12 by bolts, and the outer walls of both sides of one end of the water distribution pipe 12 are connected by bolts. Drainage pipes 13 are connected, and the peripheral outer wall of one of the drainage pipes 13 is connected with a support pipe 14 by bolts, and the outer wall of one side of the support pipe 14 is connected with atomizing nozzles 15 equidistantly arranged by bolts, and the circumference of the other drainage pipe 13 The outer wall is connected with a r...

Embodiment 2

[0037] refer to Figure 1-5 , a fabric drying device for processing textile products, further comprising a socket provided on the outer wall of the bottom of the other end of the drying box 8, and a third support plate 32 is inserted into the inner wall of the socket, and the top outer wall of the third support plate 32 is provided with a There is an installation opening, the inner wall of the installation opening is connected with a cloth pad 33 by bolts, the outer wall at one end of the third support plate 32 is connected with a limiting plate 31 through bolts, and the outer wall at one end of the limiting plate 31 is connected with a pull handle 30 through bolts.

[0038] Working principle: During the use of the device, the atomizing nozzle 15 will drop the sprinkled water mist onto the cloth pad 33, and then soak the cloth pad 33, and the thread residue brushed by the brush 26 will fall on the cloth pad 33 for a while. sticking to prevent residues from flying randomly in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com