Starch pullulanase with wide pH value adaptability and application

A technology of pullulanase and crude pullulanase, applied in the field of enzyme engineering and biomodified starch, can solve the problems of acid-base consumption, affecting the utilization of glucose syrup, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

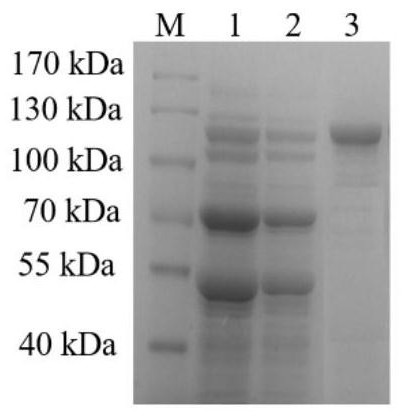

[0034] Embodiment 1: the preparation of starch pullulanase

[0035] Synthesize the gene shown in SEQ ID NO.2, insert the gene of the starch pullulanase encoded by SEQ ID NO.2 into the plasmid pET-28a (+), construct the expression vector Amypul-pET-28a (+), and insert The expression vector was introduced into the host bacteria Escherichia coli E.coli BL21(DE3) for fermentation to produce enzyme. The seed solution was inoculated into LB medium containing 50 μg / mL kanamycin at an inoculum amount of 5%, and after shaking the flask at 37°C and 160 rpm for 70 minutes, the OD value fell between 0.6-0.8. Afterwards, inducer IPTG with a final concentration of 0.4 mM was added, and cultured at 18° C. and 160 rpm for 24 hours. The fermentation broth was centrifuged at 4°C and 8000×g for 15 minutes to obtain bacterial cells. The bacteria were subjected to ultrasonic disruption (240W), and then centrifuged at 4° C. and 8000×g for 30 minutes to obtain a crude enzyme solution. The crude e...

Embodiment 2

[0036] Embodiment 2: Enzyme activity and optimum pH, pH stability test of starch pullulanase

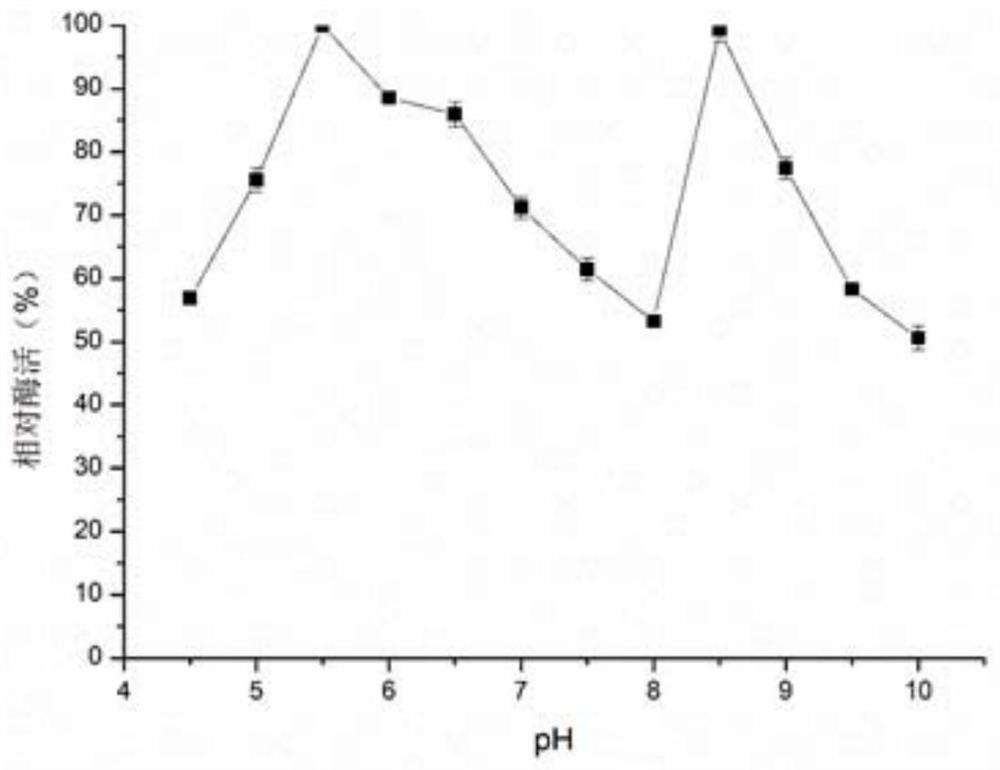

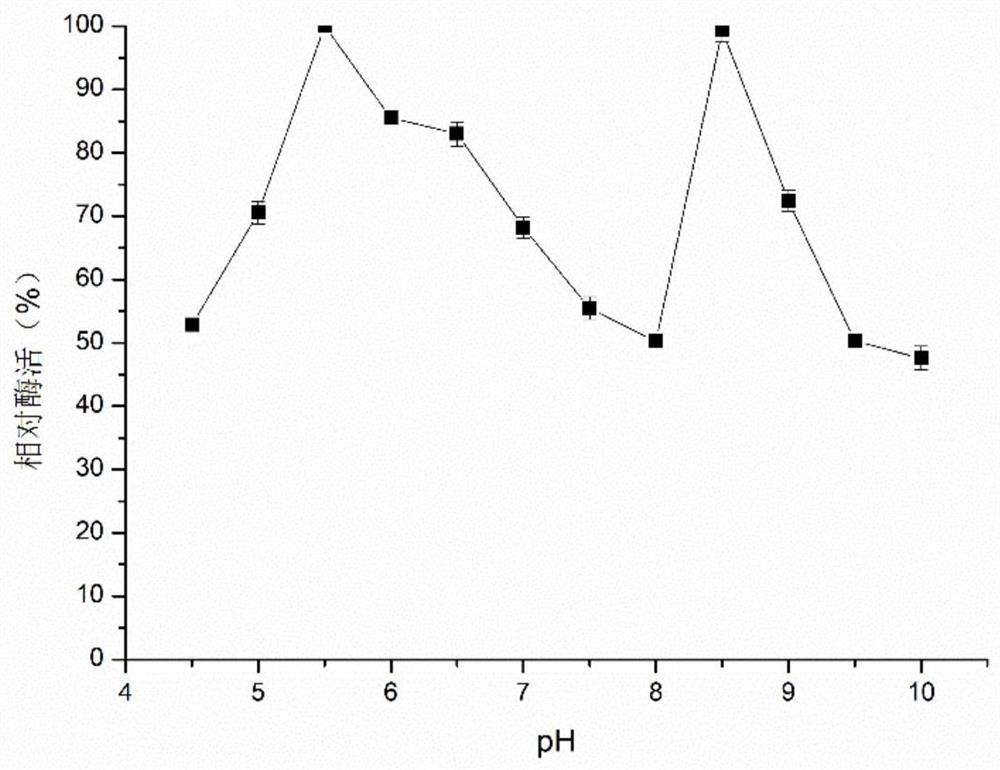

[0037] (1) Optimum pH determination of enzyme activity

[0038] Prepare buffers with pH values of 4.0, 4.5, 5.0, 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, 8.5, 9.0, 9.5, and 10.0 to replace the buffer in the enzyme activity assay of starch pullulanase at 75 The activity of starch pullulanase was measured at ℃, and the highest enzyme activity was defined as 100%, and the relative enzyme activity was calculated by comparing the rest of the enzyme activities, so as to investigate the optimal pH of the enzyme (see the test results in figure 2 ), the results showed that the starch pullulanase had the highest activity under acidic condition pH5.5 and alkaline condition pH8.5, and the activity was equal. In the range of pH 4.0-10.0, the enzyme shows stability, and the activity remains above 50%.

[0039] The optimal pH list of enzymes from other sources is shown in Table 1. It can be seen from the c...

Embodiment 3

[0045] Embodiment 3: the application of starch pullulanase in starch liquefaction

[0046] Prepare potato starch milk with a concentration of 30% (w / v), adjust the pH to 5.5, add 10U of starch pullulanase, heat up and liquefy, keep it at 75°C for 30min, measure the DE value of the reaction product, and the DE value is 14.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com