Rapid cooling system for heat-resistant high-strength cable processing

A high-strength, cable technology, applied in the field of power cables, can solve the problems of poor cooling effect, reduced cable production efficiency, and inconvenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

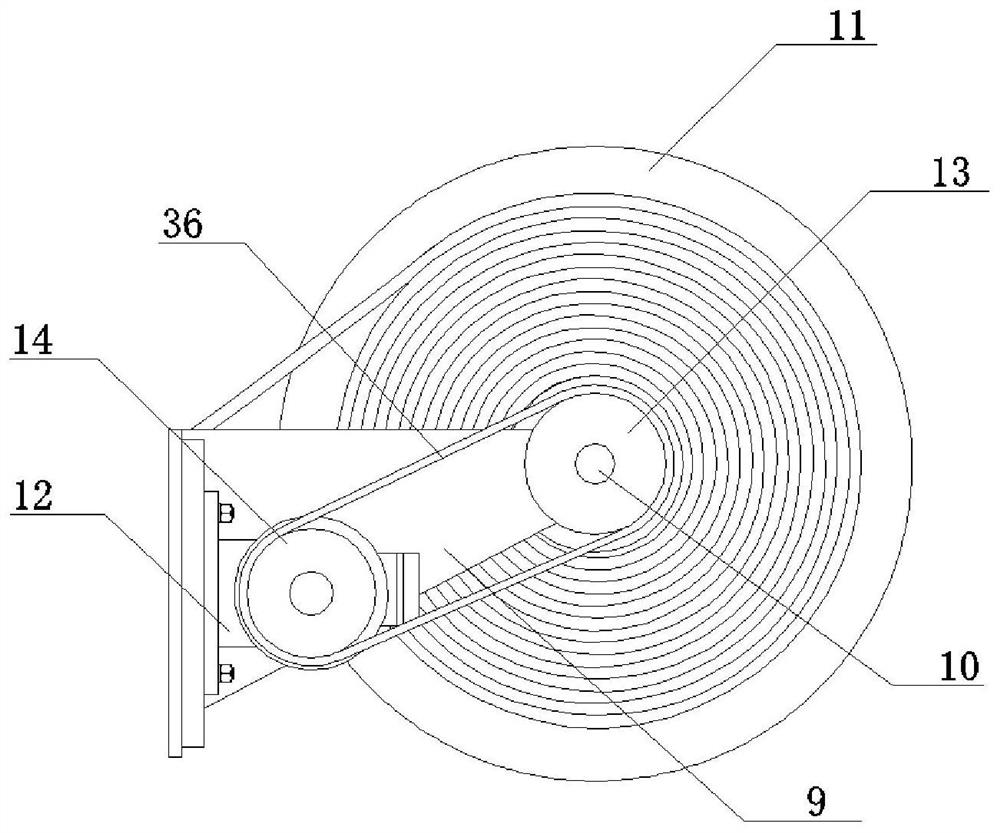

[0032] see figure 1 , a heat-resistant high-strength cable processing rapid cooling system, including a cooling water tank 1, the inside of the cooling water tank 1 is rotatably connected with two guide rollers 2, and the upper end of one side of the cooling water tank 1 is connected with 3 turns through the guide roller fixing frame. The guide roller 4, the upper end of the other side of the cooling water tank 1 is fixedly connected with a wiping assembly and a winding assembly, the cooling water tank 1 is provided with a circulating water tank 5, and the circulating water tank 5 is connected with the cooling water tank 1 through a circulating pipeline, and the circulating water tank 5 is connected with As for the cooling assembly, the upper end of the cooling water tank 5 is detachably and fixedly connected with a cooling box cover 35 , and the surface of the cooling box cover 35 is provided with a cable inlet 33 and a cable outlet 34 .

[0033] Wherein, the wiping assembly ...

Embodiment 2

[0039] A rapid cooling system for heat-resistant high-strength cable processing, specifically including the following steps:

[0040] Step 1, the cooling assembly cools the coolant in the water cooling box 31 through the evaporating tube 5;

[0041] Step 2, the circulating water pump 20 draws the cooling liquid inside the circulating water tank 5 into the water outlet pipe 18 through the water pump 21, and guides the cooling liquid into the cooling water tank 1 through the water outlet pipe 18;

[0042] Step 3, cable is passed guide roller 4, the cable inlet 33 of cooling box cover 35, two guide rollers 2, the cable outlet 34 of cooling box cover 35 and two wiping rollers 7, cover cooling box cover 35, and make The cable is wound and connected through the winding roller 10;

[0043] Step 4, start the winding motor 12, the winding motor 12 drives the winding roller 10 to rotate, the winding roller 10 drives the cable for winding, the cable enters the cooling water tank 1 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com