Method for manufacturing pre-filling type syringe comprising local anesthetic and hyaluronic acid hydrogel

A technology of local anesthetic and hyaluronic acid, applied in syringes, ampoule syringes, medical preparations containing active ingredients, etc., can solve problems such as slow release of lidocaine, and achieve the effect of excellent initial dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

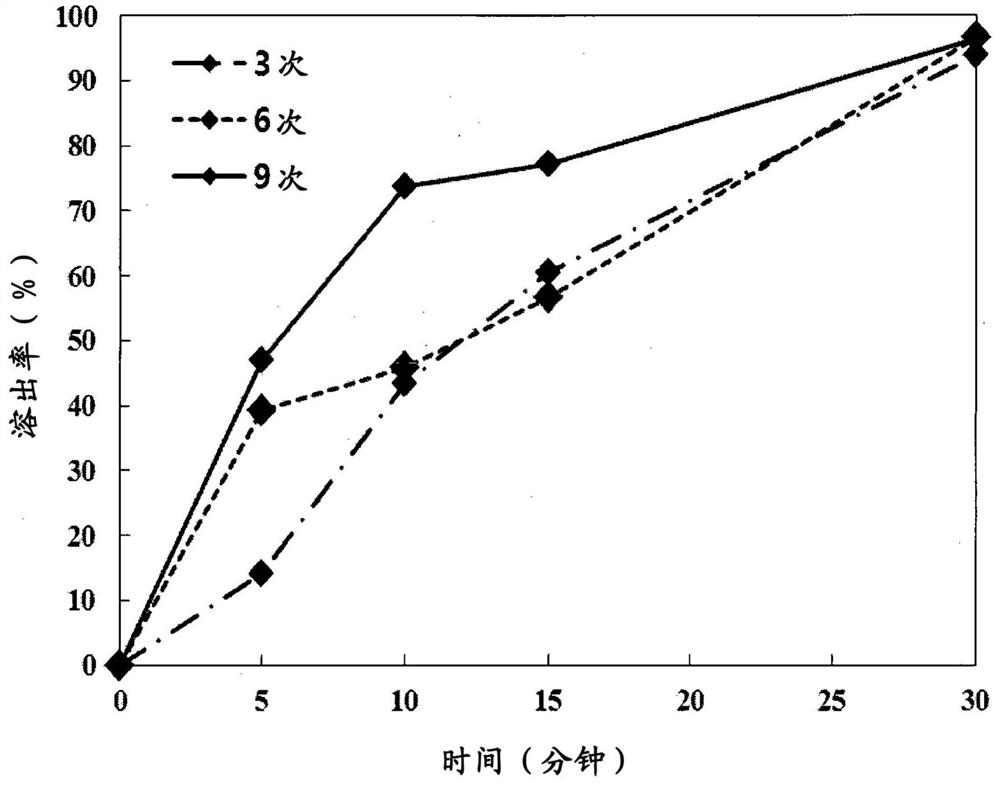

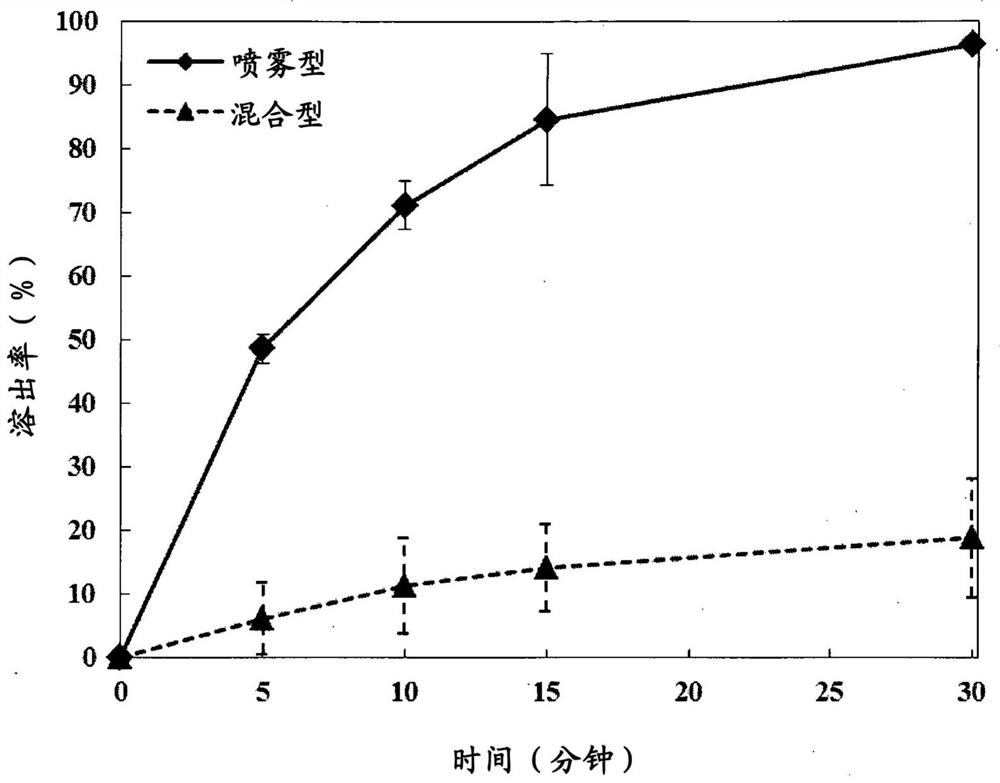

[0051] Embodiment 1: Comparative test of the release rate of lidocaine carried out according to the method of adding lidocaine

[0052] 1. Purpose of the experiment

[0053] The release rate according to the method of adding lidocaine to the hyaluronic acid (hereinafter referred to as "HA") cross-linked composition was compared to confirm the stability.

[0054] 2. Test Substances and Preparation

[0055] 2.1 Test substances

[0056] Table 1

[0057] category HA concentration (mg / mL) Lidocaine concentration (%) for mixing 24 0.03 for spray 24 10.0

[0058] 2.2 Preparation of test substances

[0059] According to the method of adding lidocaine hydrochloride, test substances were prepared as follows.

[0060] (1) Gel mixed type

[0061] After 0.03 g of lidocaine hydrochloride was dissolved in 100 mL of PBS, 2.4 g of cross-linked hyaluronic acid was added thereto for swelling to prepare a hydrogel.

[0062] (2) In-syringe spray type

[0063...

Embodiment 2

[0096] Example 2: Comparison of loading and dissolution rates of lidocaine according to syringe material / syringe volume

[0097] In order to compare the loading rate and dissolution rate of lidocaine according to the syringe material / syringe volume, experiments were performed to determine the loading rate and dissolution rate of lidocaine according to the following conditions.

[0098] 1) Syringe material: cycloolefin copolymer (COC)

[0099] 2) Syringe volume: 1mL, 3mL, 10mL

[0100]

[0101] -PBS solution, 37°C

[0102] - Lidocaine solution concentration: 10%

[0103] -Method: After spraying in a syringe 3 times, dry in a drying oven at 70°C

[0104] -Number of spray repetitions: based on 9

[0105] The loading and dissolution rates of lidocaine by syringe volume are shown in Tables 4 and 5 below.

[0106] Table 4 compares the loading rates of lidocaine solutions by syringe volume

[0107] category Lidocaine concentration (mg / mL) COC 1mL 3.23 C...

Embodiment 3

[0113] Example 3: Confirmation of the effect of the composition of the lidocaine spray solution

[0114] In order to confirm whether injections can be produced according to the hyaluronic acid concentration of the lidocaine spray solution, the lidocaine spray solution was prepared in PBS and sprayed according to the following concentrations, and the results are shown in Table 7 below.

[0115] Table 7

[0116]

[0117] As can be seen from Table 7, when the concentration of hyaluronic acid was 0.1 (w / v)% or more and less than 1.0, it was confirmed that injections could be prepared by proper spraying even if the concentration of lidocaine was the same.

[0118] Subsequently, according to the number of sprays of the lidocaine spray solution containing 0.1 and 0.5 (w / w)% hyaluronic acid, the loading rate and the dissolution rate showing the desired spray effect of lidocaine were determined. The experimental conditions are as follows. The results are shown in Tables 8 and 9 be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

| Absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com