Method for enzymatic degradation of hyaluronic acid or salt thereof

A technology of hyaluronidase and hyaluronic acid, which is applied in the field of hyaluronic acid or its salt enzyme degradation, can solve the problems of hyaluronidase activity reduction, bovine serum albumin is expensive, and cannot be applied on a large scale, so as to improve The effect of enzymatic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

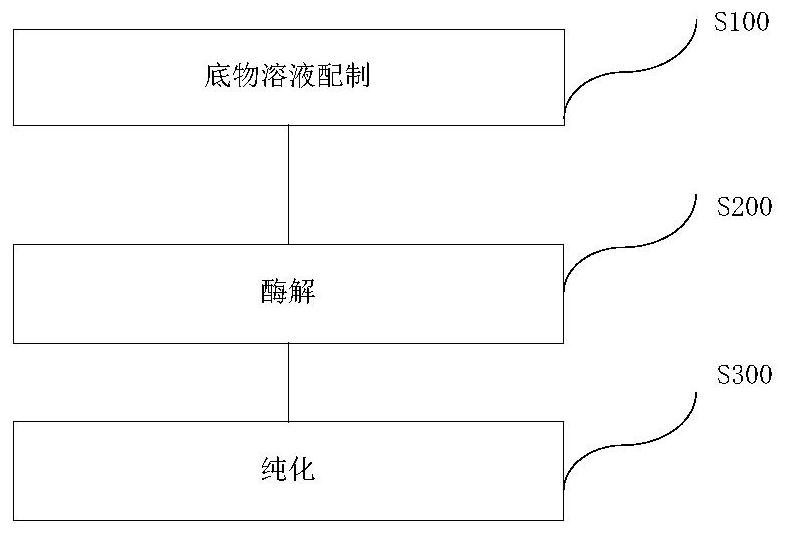

Method used

Image

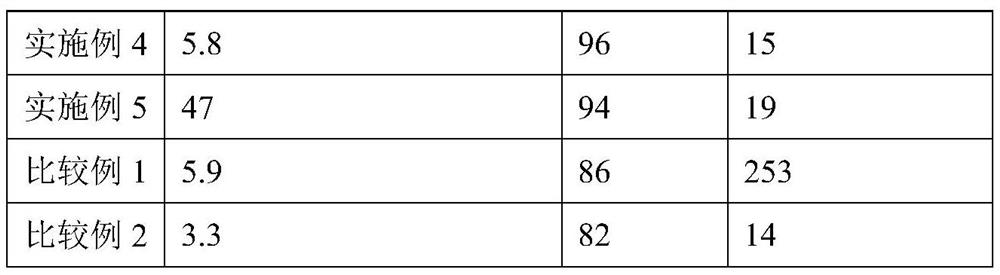

Examples

Embodiment 1

[0048] 1. To 1.5m 3 Add 1m to the stainless steel dissolution tank 3 Purify water, heat up to 40°C, adjust the pH to 6.0, set the stirring speed to 20rpm, and add 400g of glucose and 50g of glucose oxidase to the dissolution tank sequentially while stirring.

[0049] 2. After stirring for 3 minutes, slowly add 300 kg of sodium hyaluronate with a molecular weight of 1000 kDa, and stir for 0.5 to 1 hour after the hyaluronic acid is completely added.

[0050] 3. Add 8.0×10 to the sodium hyaluronate solution 10 IU of hyaluronidase until the enzymatic hydrolysis reaches the desired molecular weight, and the enzymatic hydrolysis ends.

[0051] 4. Add ethanol to the enzymolysis solution until the alcohol content of the enzymolysis solution reaches 25%, stir for 0.5-1 hour, filter, and collect the filtrate.

[0052] 5. Add 20 times the volume of ethanol to the filtrate. At this time, the alcohol content of the filtrate is about 92%, and sodium hyaluronate is precipitated. The prec...

Embodiment 2

[0055] 1. To 1.5m 3 Add 1m to the stainless steel dissolution tank 3 Purify water, heat up to 40°C, adjust the pH to 6.0, set the stirring speed to 20rpm, and add 200g of glucose and 30g of glucose oxidase to the dissolution tank sequentially while stirring.

[0056] 2. After stirring for 3 minutes, slowly add 100 kg of calcium hyaluronate with a molecular weight of 2500 kDa, and stir for 0.5 to 1 hour after the hyaluronic acid is completely added.

[0057] 3. Add 5.0×10 to the sodium hyaluronate solution 11 IU of hyaluronidase until the enzymatic hydrolysis reaches the desired molecular weight, and the enzymatic hydrolysis ends.

[0058] 4. Add ethanol to the enzymolysis solution until the alcohol content reaches 20%, stir for 0.5-1 hour, filter, and collect the filtrate.

[0059] 5. Add 3 times the volume of ethanol to the filtrate, the alcohol content of the filtrate is about 76% at this time, and sodium hyaluronate is precipitated. The precipitate is dehydrated with et...

Embodiment 3

[0062] 1. To 1.5m 3 Add 1m to the stainless steel dissolution tank 3 Purify water, heat up to 40°C, adjust the pH to 6.0, set the stirring speed to 20rpm, and add 100g of glucose and 10g of glucose oxidase to the dissolution tank sequentially while stirring.

[0063] 2. After stirring for 3 minutes, slowly add 50 kg of potassium hyaluronate with a molecular weight of 3000 kDa, and stir for 0.5 to 1 hour after the hyaluronic acid is completely added.

[0064] 3. Add 5.0×10 to the sodium hyaluronate solution 8 IU of hyaluronidase until the enzymatic hydrolysis reaches the desired molecular weight, and the enzymatic hydrolysis ends.

[0065] 4. Add ethanol to the enzymolysis solution until the alcohol content reaches 35%, stir for 0.5-1 hour, filter, and collect the filtrate.

[0066] 5. Add 5 times the volume of ethanol to the filtrate, and the alcohol content of the filtrate is about 80% at this time, to obtain sodium hyaluronate precipitation. The precipitate is dehydrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com