Nicotine liquid culture medium, application and activation fermentation device

A technology of culture medium and nicotinic liquid, which is applied in biochemical cleaning devices, bioreactor/fermenter combinations, bioreactors/fermenters for specific purposes, etc., can solve the problem of inaccurate spraying amount and poor protection of activated bacteria. , activated bacteria pollution and other problems, to improve the quality of fermentation bacteria, the production method is scientific and reliable, and the effect of increasing the amount of organic fertilizer inoculum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

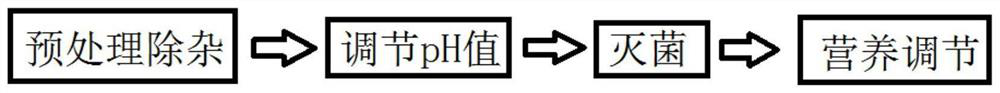

[0022] A kind of nicotine liquid culture medium, its processing method comprises the following steps:

[0023] 1) Pretreatment to remove impurities: put the nicotine liquid in a pool, and remove impurities through natural sedimentation;

[0024] 2) adjust the pH value: extract the supernatant and adjust the pH value between 6-7 with ammonia water;

[0025] 3) Sterilization: Sterilize at a temperature of 121 degrees for 15-30 minutes;

[0026] 4) Nutrition adjustment: adjust the content of amino acid, protein and sugar according to the type of bacteria to be cultivated, and then store it under sterile conditions for later use.

[0027] As a preference, the steps of its processing method of the present invention: 2) adjust the pH value: extract the supernatant and adjust its pH value to 6-6.5 with ammonia water; 30 minutes.

[0028] The strains cultivated by using the nicotine liquid medium in the present invention are: thermophilic Bacillus Geobacillus kaustophilus, Candida ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com