Polishing disc swing polishing machine used for leather padding

A polishing machine and swing mechanism technology, applied in the field of machinery, can solve the problems of lower product production efficiency, low work efficiency, and inability to throw and swing, and achieve the effects of preventing iron filings from splashing, reducing resource waste and production costs, and facilitating reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

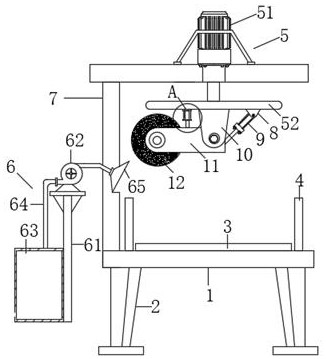

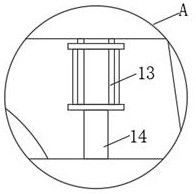

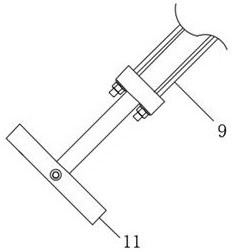

[0021] Example: such as Figure 1-4 As shown, a disc throwing and swinging polishing machine for leather soft bags includes a base 1, a workbench 3 is fixedly installed on the upper surface of the base 1, a material retaining plate 4 is fixedly installed on one side of the upper surface of the base 1 through fixing screws, and the upper surface of the base 1 The other side is fixedly installed with a support rod 7, the outer wall of the base 1 close to the support rod 7 is fixed with a dust suction mechanism 6, the top of the support rod 7 is fixedly installed with a top plate, the upper surface of the top plate is provided with a swing mechanism 5, and the lower surface of the swing mechanism 5 The center is fixedly equipped with a fixed seat 10, and the inside of the fixed seat 10 is connected with a connecting rod 11 through the rotation of the rotating shaft. One side of the connecting rod 11 is provided with a first chute 15, and the top of the connecting rod 11 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com