Radiator reinforcement clip automatic assembly line

A technology of reinforcing clips and radiators, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of difficult automatic orthopedics, uncontrolled deformation of reinforcing clips, large insertion position errors, etc., and achieve resistance to self-fatigue strength , Improving the durability and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

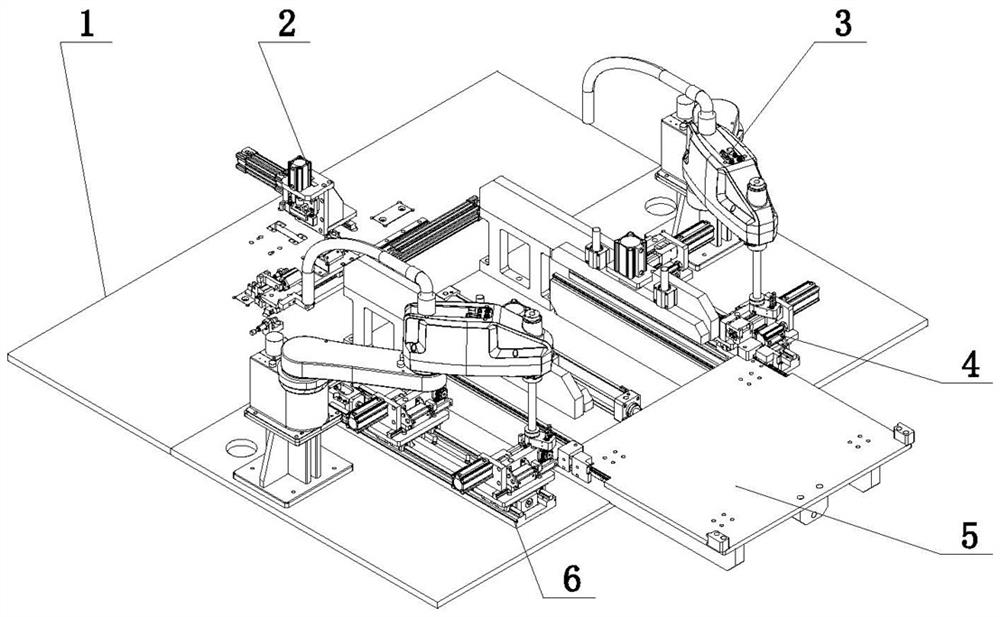

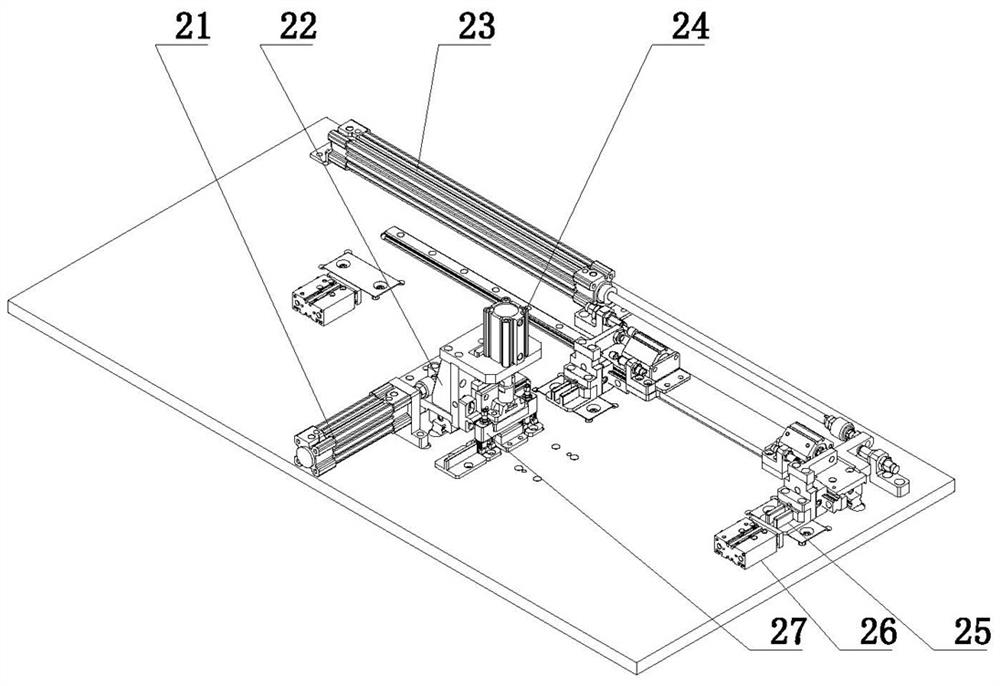

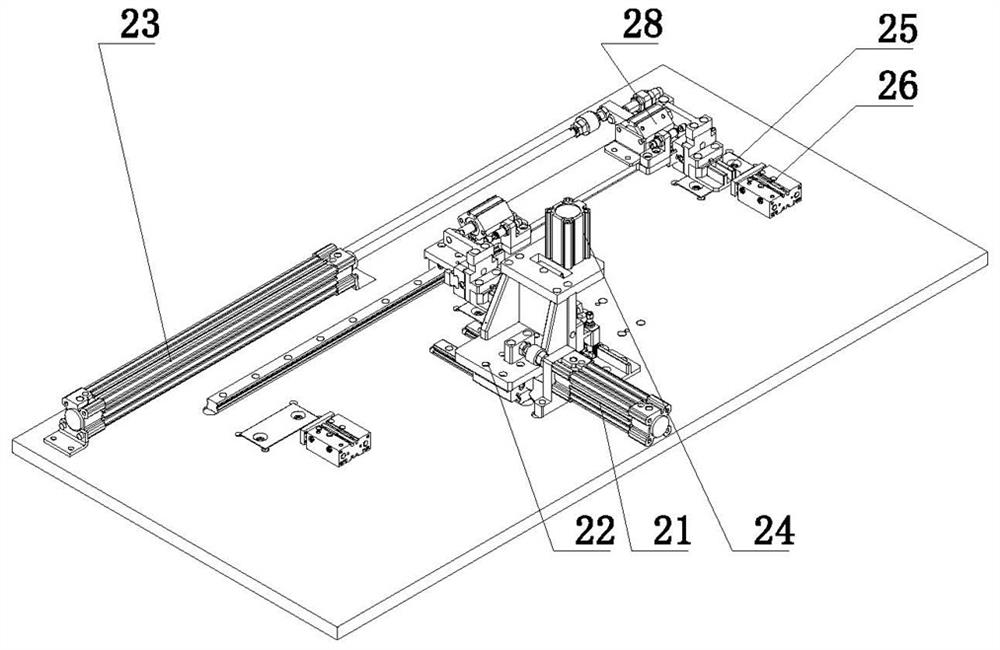

[0036] The present invention includes a workbench 1, which is characterized in that: the workbench 1 is provided with an orthopedic mechanism 2 and a clip mold device 4, and the workbench 1 is provided with a handling manipulator 3 corresponding to the orthopedic mechanism 2 and the clip mold device 4; Described orthopedic mechanism 2 comprises the telescopic cylinder 21 that is arranged on the workbench 1, and telescopic cylinder 21 links to each other with a moving frame 22, and the moving frame 22 is provided with the pressing down cylinder 24 of pressing down mold 27, and down pressing mold 27 is provided with The workpiece suction port connected to the negative pressure mechanism 29; the bottom of the workbench 1 is provided with a jacking mold 212 that cooperates with the pressing mold 27 through a jacking cylinder 211; the workbench 1 is provided with a loading frame 25 through a transmission cylinder 23, The loading station of the loading rack 25 corresponds to the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com