Horizontal type two-roller rolling mill with rapid roller changing function

A rolling mill, horizontal technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve problems such as bearing deformation and damage, and achieve the effect of improving service life, improving accuracy and quality, and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in further detail below in conjunction with the accompanying drawings.

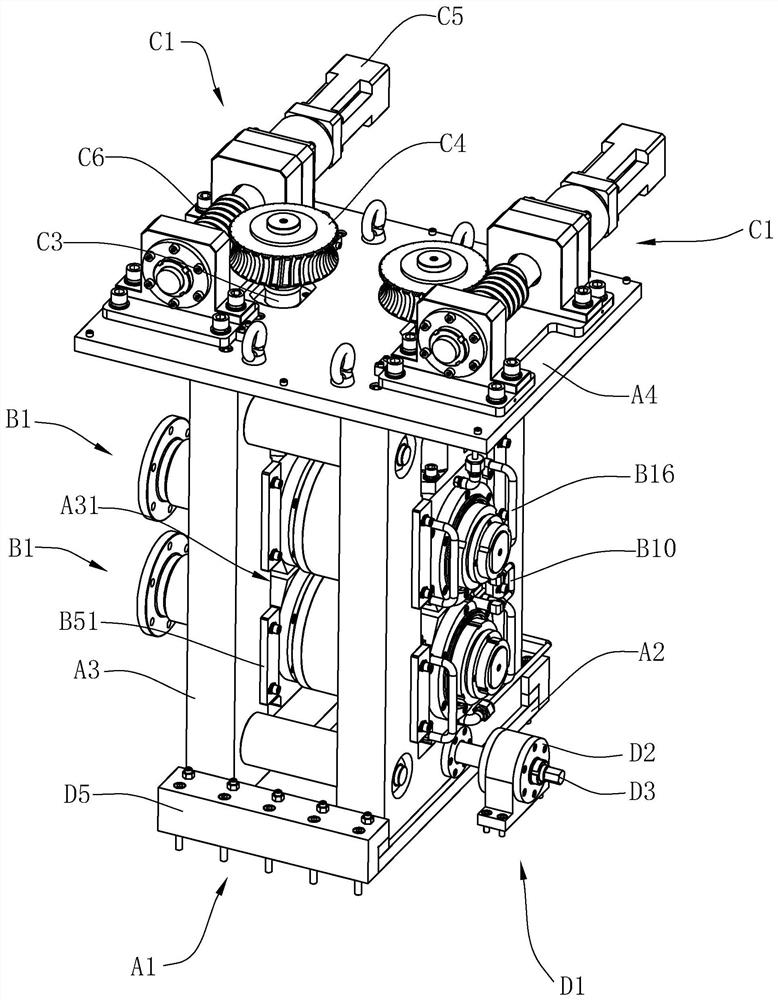

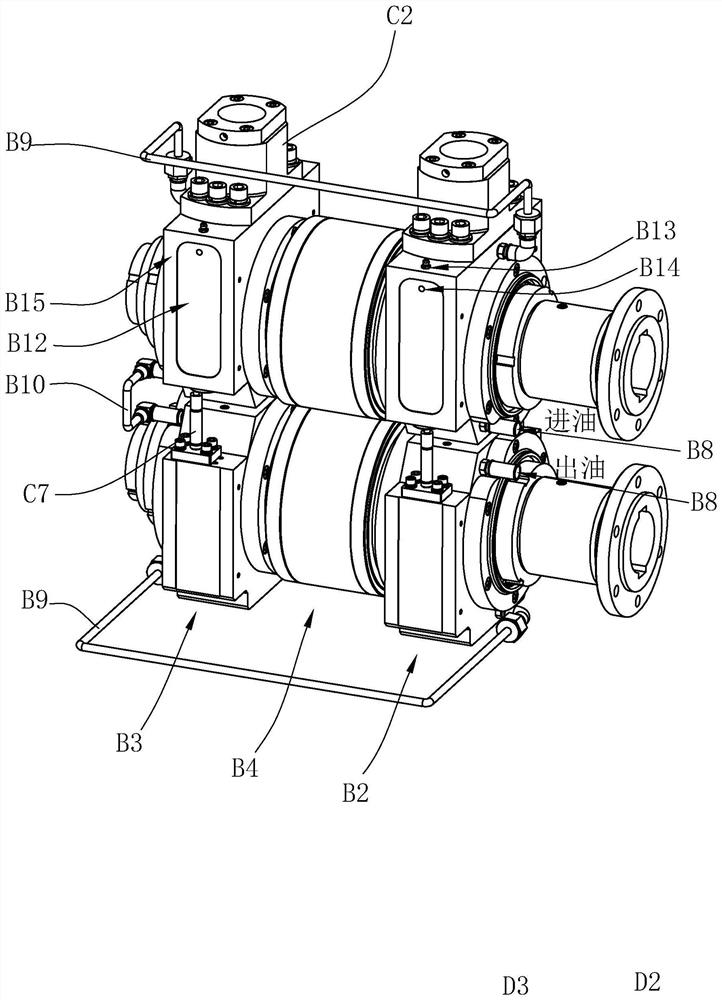

[0060] Such as figure 1 As shown, a fast roll-changing horizontal two-roll rolling mill includes a frame A1, and the frame A1 includes a base A2 arranged in sequence from bottom to top, a pair of symmetrical mounting plates A3 and a top cover A4, and between the mounting plates A3 The four corners are connected with fixed columns, and there is an installation groove A31 running through the installation plate A3 along its thickness direction, and the installation groove A31 is extended along the vertical direction. The rolling unit B1 is distributed at intervals in the vertical direction, and the rolling unit B1 includes a left roll support assembly B2, a roll assembly B4, and a right roll support assembly B3 arranged in sequence along the horizontal direction, wherein the left roll support assembly B2 and the right roll support assembly B3 They are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com