Aerogel composite membrane and preparation method and application thereof

An airgel and composite membrane technology, applied in the field of membrane distillation, can solve the problems of high thermal conductivity, potential pollution, and high cost of membrane production, and achieve the effect of green and convenient preparation process and guaranteed mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Mix methyltriethoxysilane with ethanol and water at a mass ratio of 1:2.5:1.5, and stir at room temperature for 24 hours to obtain a uniform sol; then, add ammonia water to adjust the pH of the sol to 9-10 , stirred for 1 hour; PP non-woven fabric (thickness about 0.45mm) was immersed in the sol solution after the pH adjustment, took out and placed in a glass plate mold and controlled relative pressure to be 100Pa, let it stand for 10 hours, and then transferred to Aging in an oven at 50°C for 5 hours to prepare a wet film; finally, take the wet film out of the mold and dry it in an oven at 80°C for 1 hour to obtain a superhydrophobic low thermal conductivity airgel composite film.

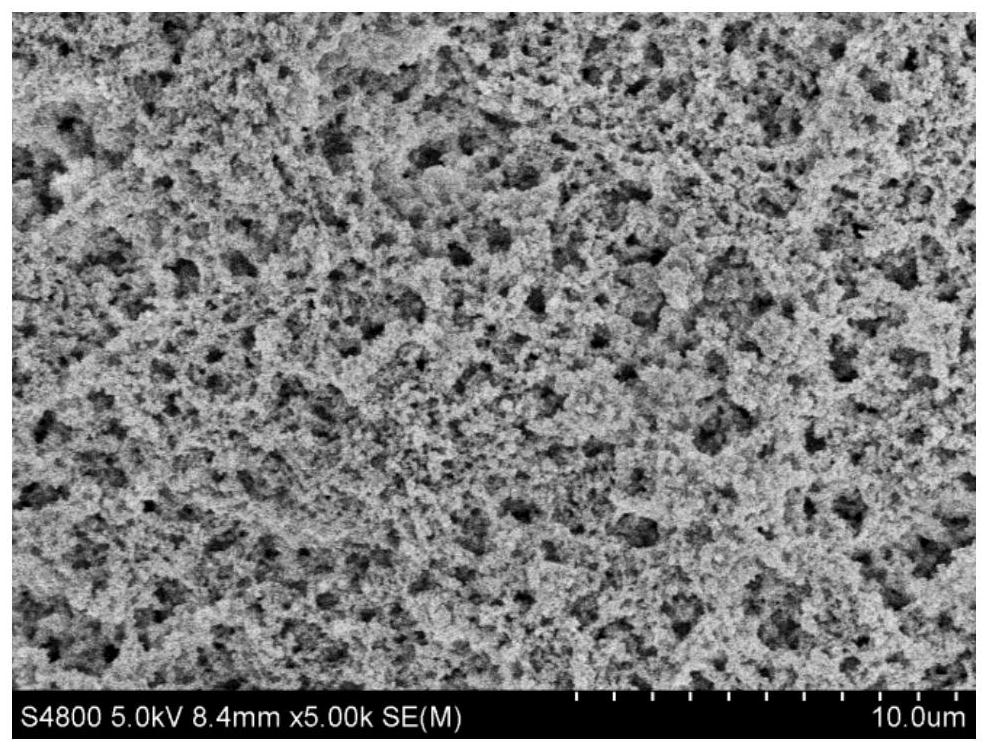

[0060] The average thickness of the airgel composite film is 0.48mm, and its microscopic surface morphology is as attached figure 1 As shown, the silica particles formed by sol-gel stacked in the pores of the nonwoven fabric to form a three-dimensional network structure with abundant pores....

Embodiment 2

[0064] Mix methyltrimethoxysilane, ethanol and water at a mass ratio of 1:2.5:1.5, and stir at room temperature for 24 hours to obtain a uniform sol; then, add ammonia water to adjust the pH of the sol to 9-10, and stir 1 hour; soak the PP non-woven fabric in the pH-adjusted sol solution, take it out and place it in a glass plate mold and control the relative pressure to 100Pa, let it stand for 10 hours, and then transfer it to an oven at 50°C for aging for 5 hours. A wet film was prepared; finally, the wet film was taken out of the mold and dried in an oven at 80°C for 1 hour to obtain a superhydrophobic low thermal conductivity airgel composite film. The airgel composite film has a hydrophobic angle of 154°, a sliding angle of 8°, and a thermal conductivity of 0.035W·K -1 m -1 .

Embodiment 3

[0066] Mix methyltriethoxysilane with ethanol and water at a mass ratio of 1:2.5:1.5, and stir at room temperature for 24 hours to obtain a sol with uniform properties; then, add ammonia water to adjust the pH of the sol to 9-10, Stir for 1 hour; soak the PTFE / PP non-woven fabric in the pH-adjusted sol solution, take it out and place it in a glass plate mold with a relative pressure of 100 Pa, let it stand for 10 hours, and then transfer it to an oven at 50°C for aging After 5 hours, a wet film was prepared; finally, the wet film was taken out from the mold and placed in an oven at 80° C. for 1 hour to dry to obtain a hydrophobic low thermal conductivity airgel composite film. The hydrophobic angle of the airgel composite film is 140°, the sliding angle is 28°, and the thermal conductivity is 0.053W·K -1 m -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com