Mining wet dust collector

A wet dust collector, mining technology, applied in the direction of using liquid separation agent, chemical instruments and methods, separation devices, etc., can solve the problems of simple structure, low dust capture and purification rate, low dust removal efficiency, etc., to improve dust reduction efficiency, Good dust suppression effect and the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

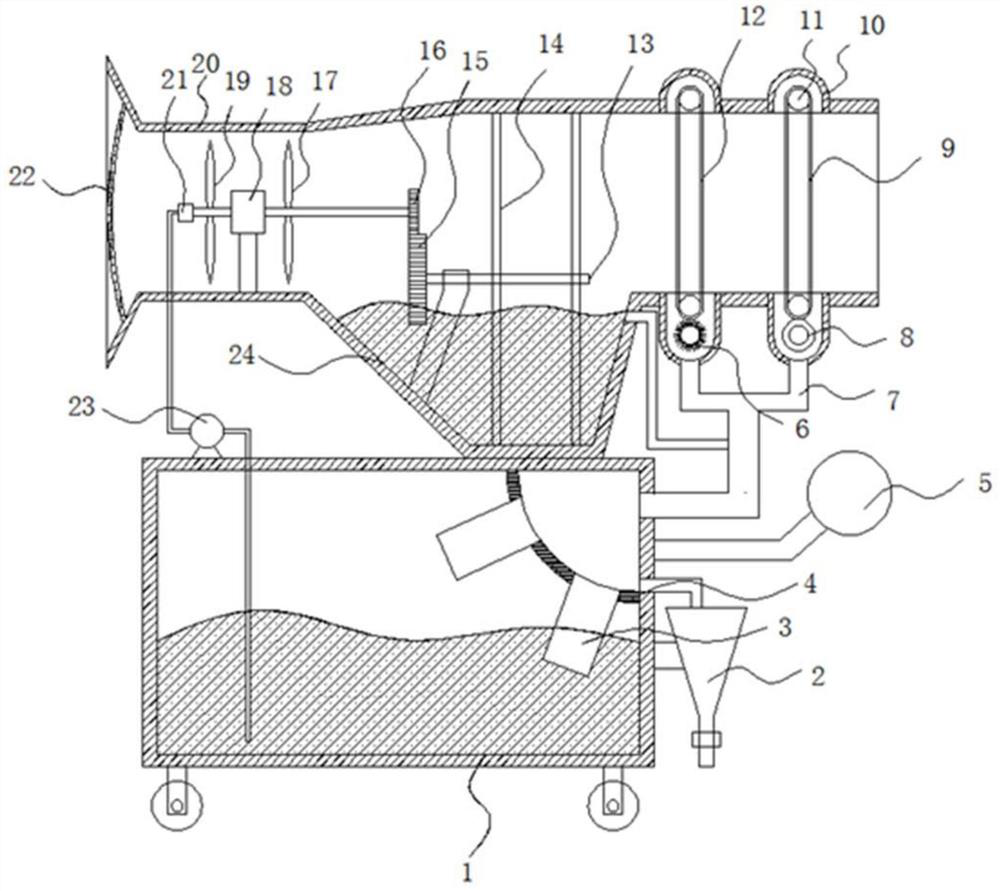

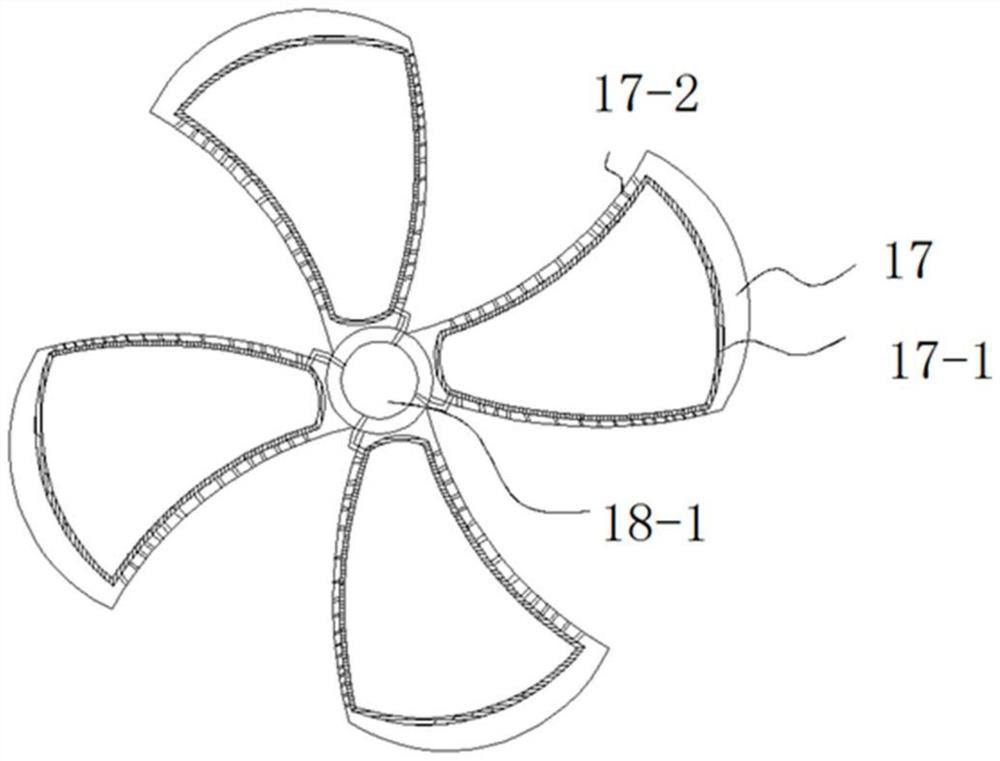

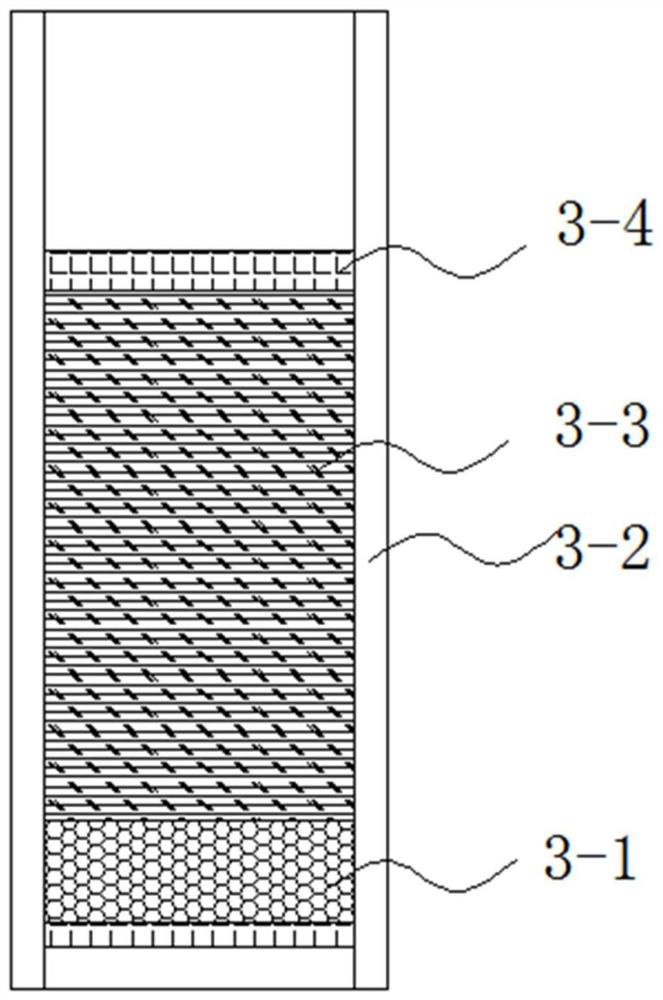

[0030] refer to Figure 1-4 , a mining wet dust collector, including a water storage tank 1 and an air cylinder 20 installed on its top, the water storage tank 1 is provided with a filter mechanism, and the filter mechanism includes an arc-shaped partition plate 4 installed on the top of the water storage tank 1 One side of the partition plate 4 is connected with the ash collecting hopper 2 fixed on the outer wall of the water storage tank 1 through a conduit, and a plurality of filter cartridges 3 are installed on the partition plate 4, and the two ends of the filter cartridge 3 are connected with the partition plate 4 respectively. The two sides of the two sides ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com