A heat treatment method for eliminating the laves phase in the β phase in superalloy inconel783 bolts

A heat treatment method and high-temperature alloy technology, which is applied in the field of alloy heat treatment, can solve problems such as the decrease of plasticity and toughness, destroy the original structure of β phase, and affect the safety of bolts, and achieve the effect of restoring strength, plasticity and toughness, and refining size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

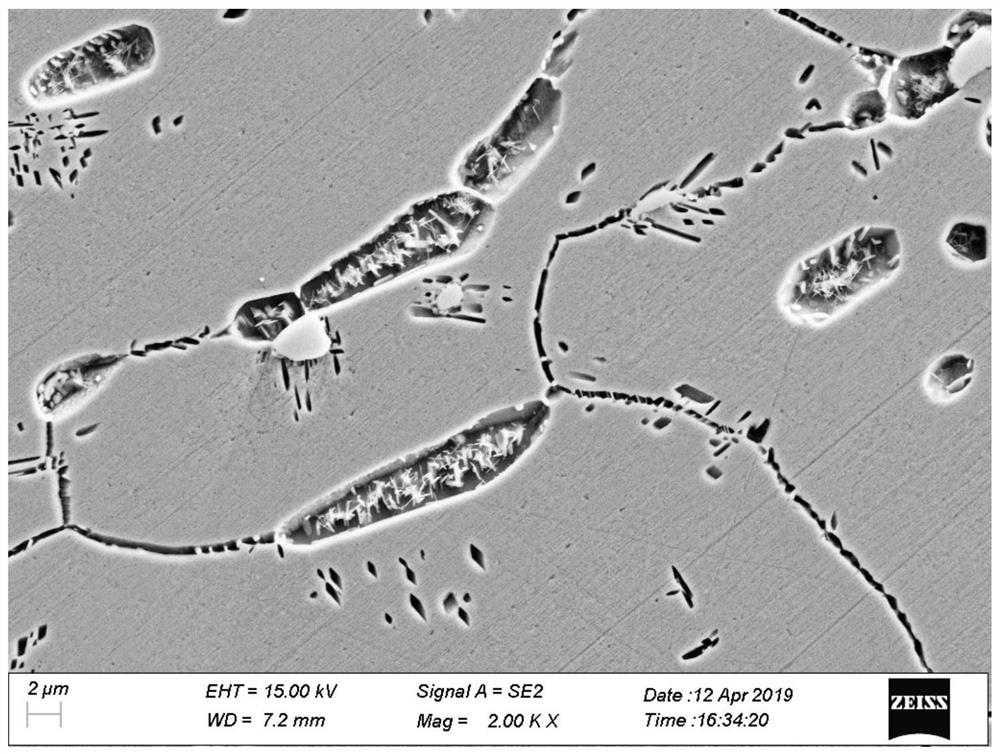

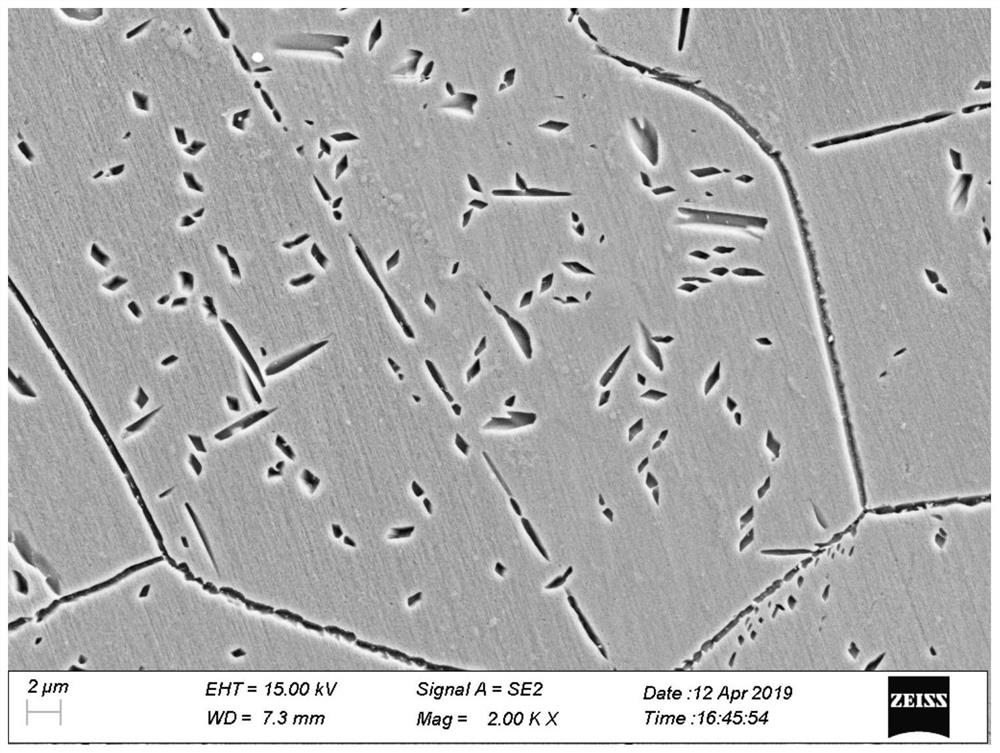

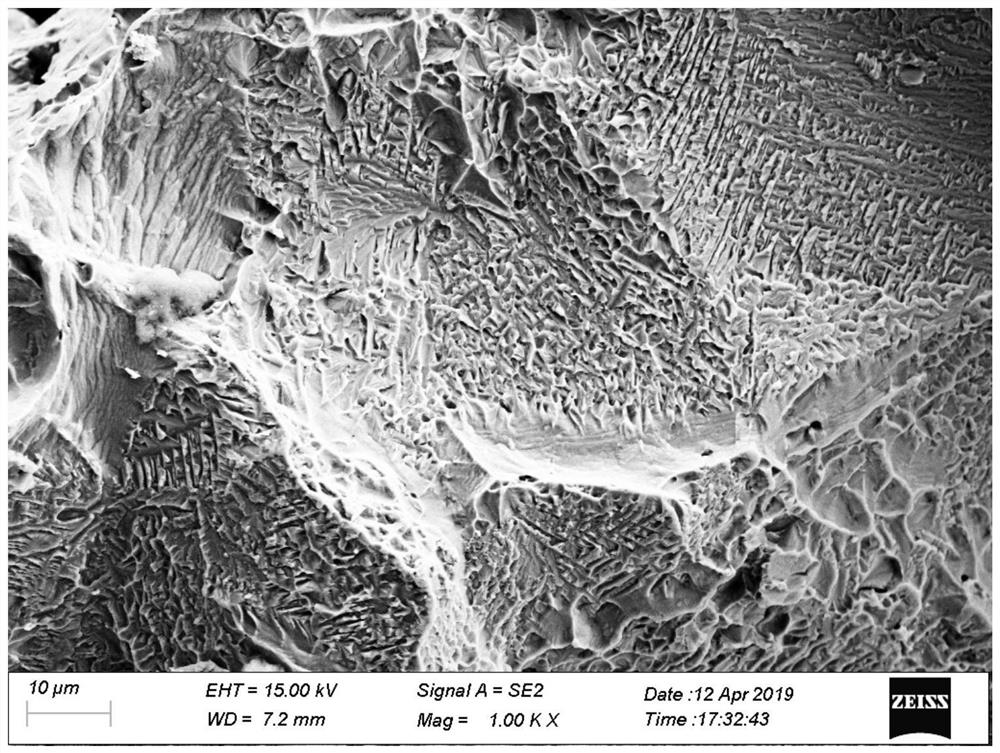

[0023] In this embodiment, the heat treatment method for eliminating the laves phase in the β phase in the superalloy inconel783 bolt is as follows:

[0024] 1. Solution treatment: Select the inconel783 superalloy bolt with Laves phase after the main valve of the 660MW supercritical unit is in service, cut the sample from the inconel783 superalloy bolt axially, and put the sample into the KSL-1400X box-type resistance furnace Heat up to 1100°C at a heating rate of 5°C / min, hold for 1 hour, and air cool to room temperature;

[0025] 2. β aging treatment: put the sample after solid solution treatment into KSL-1400X box-type resistance furnace, heat up to 840°C at a heating rate of 5°C / min, keep it warm for 6 hours, and air cool to room temperature;

[0026] 3. γ' aging treatment: put the sample after β aging treatment into the KSL-1400X box-type resistance furnace, the heating rate is 5 ℃ / min, the temperature is raised to 720 ℃, kept for 8 hours, and cooled to 630 ℃ with the fur...

Embodiment 2

[0028] In this embodiment, the heat treatment method for eliminating the laves phase in the β phase in the superalloy inconel783 bolt is as follows:

[0029] 1. Solution treatment: Select the inconel783 superalloy bolt with Laves phase after the main valve of the 660MW supercritical unit is in service, cut the sample from the inconel783 superalloy bolt axially, and put the sample into the KSL-1400X box-type resistance furnace Heat up to 1110°C at a heating rate of 5°C / min, hold for 1 hour, and air cool to room temperature;

[0030] 2. β aging treatment: put the sample after solid solution treatment into KSL-1400X box-type resistance furnace, heat up to 840°C at a heating rate of 5°C / min, keep it warm for 6 hours, and air cool to room temperature;

[0031] 3. γ' aging treatment: put the sample after β aging treatment into the KSL-1400X box-type resistance furnace, the heating rate is 5 ℃ / min, the temperature is raised to 720 ℃, kept for 8 hours, and cooled to 630 ℃ with the fur...

Embodiment 3

[0033] In this embodiment, the heat treatment method for eliminating the laves phase in the β phase in the superalloy inconel783 bolt is as follows:

[0034] 1. Solution treatment: Select the inconel783 superalloy bolt with Laves phase after the main valve of the 660MW supercritical unit is in service, cut the sample from the inconel783 superalloy bolt axially, and put the sample into the KSL-1400X box-type resistance furnace Heat up to 1120°C at a heating rate of 5°C / min, hold for 1 hour, and air cool to room temperature;

[0035] 2. β aging treatment: put the sample after solid solution treatment into KSL-1400X box-type resistance furnace, heat up to 840°C at a heating rate of 5°C / min, keep it warm for 6 hours, and air cool to room temperature;

[0036] 3. γ' aging treatment: put the sample after β aging treatment into the KSL-1400X box-type resistance furnace, the heating rate is 5 ℃ / min, the temperature is raised to 720 ℃, kept for 8 hours, and cooled to 630 ℃ with the fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com