Amphiphilic bottle brush type polymer as well as preparation method and application thereof

A bottle-brush type, amphiphilic technology, applied in the field of petroleum drilling fluid, to achieve the effect of simple process, mild reaction conditions, and expanded industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

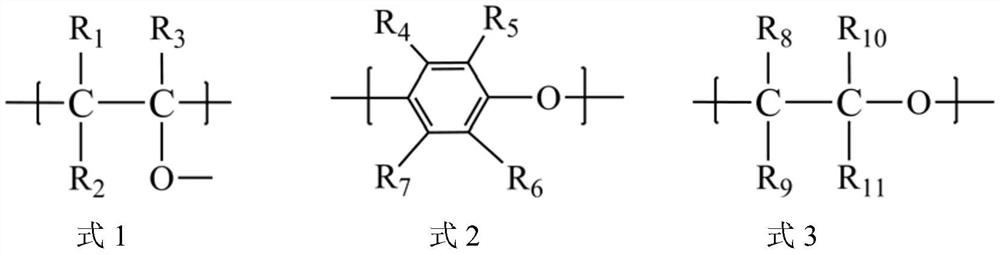

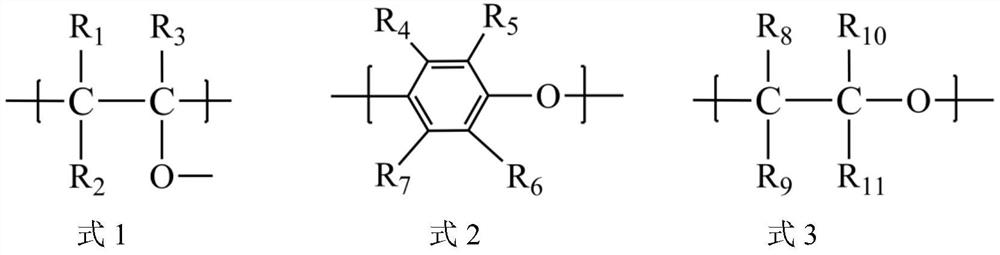

Method used

Image

Examples

Embodiment 1

[0075] Add 2 g of polyvinyl alcohol (PVA, weight average molecular weight 50,000) and 30 mL of N,N-dimethylacetamide (DMA) into the flask, and slowly raise the temperature to 60° C. to dissolve the PVA. After the PVA solution was cooled to room temperature, 11.25 g of isocyanate-terminated polyphenylene ether (PPO-NCO, weight average molecular weight 5000) was added thereto and mixed uniformly. The reaction was incubated at 60° C. for 3 h to obtain a PVA-g-PPO solution. Then, 68 g of isocyanate-terminated polyethylene glycol (PEG-NCO, weight average molecular weight 5000) was added to the PVA-g-PPO solution, and the reaction was incubated for 2 hours to obtain a solution of the product PVA-g-(PPO-co-PEG). The product solution was vacuum-dried at 80°C and pulverized to obtain a powdered bottle-brush polymer PVA 50000 -g-(PPO 5000 -co-PEG 5000 ). According to the feed ratio of reactants, the grafting degree of PPO is 5%, and the grafting degree of PEG is 30%.

[0076] Add 10...

Embodiment 2

[0078] The only difference with Example 1 is that 2g polyvinyl alcohol (PVA, weight-average molecular weight 100,000) is added to the flask to obtain powdered bottle brush type polymer PVA 100000 -g-(PPO 5000 -co-PEG 5000), the resulting lubricant product is A2.

Embodiment 3

[0080] The only difference from Example 1 is that after the PVA solution is cooled to room temperature, 6.82 g of isocyanate-terminated polyphenylene ether (PPO-NCO, weight average molecular weight 3000) is added thereto and mixed uniformly to obtain a powdered bottle brush type polymer PVA 50000 -g-(PPO 3000 -co-PEG 5000 ), the resulting lubricant product is A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com