Phosphorus-free composite water treatment agent and application thereof

A water treatment and medicament technology, applied in the field of water treatment, can solve the problems of general corrosion inhibitor treatment effect, achieve excellent corrosion inhibition function, improve water quality, and reduce corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

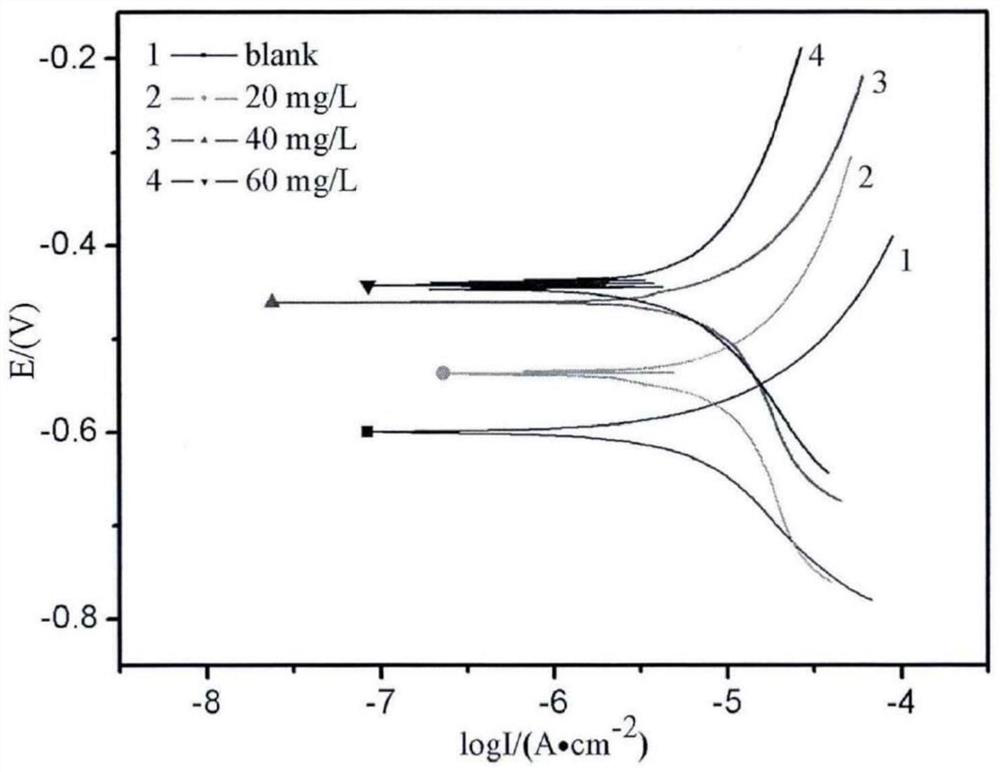

Problems solved by technology

Method used

Image

Examples

preparation example Construction

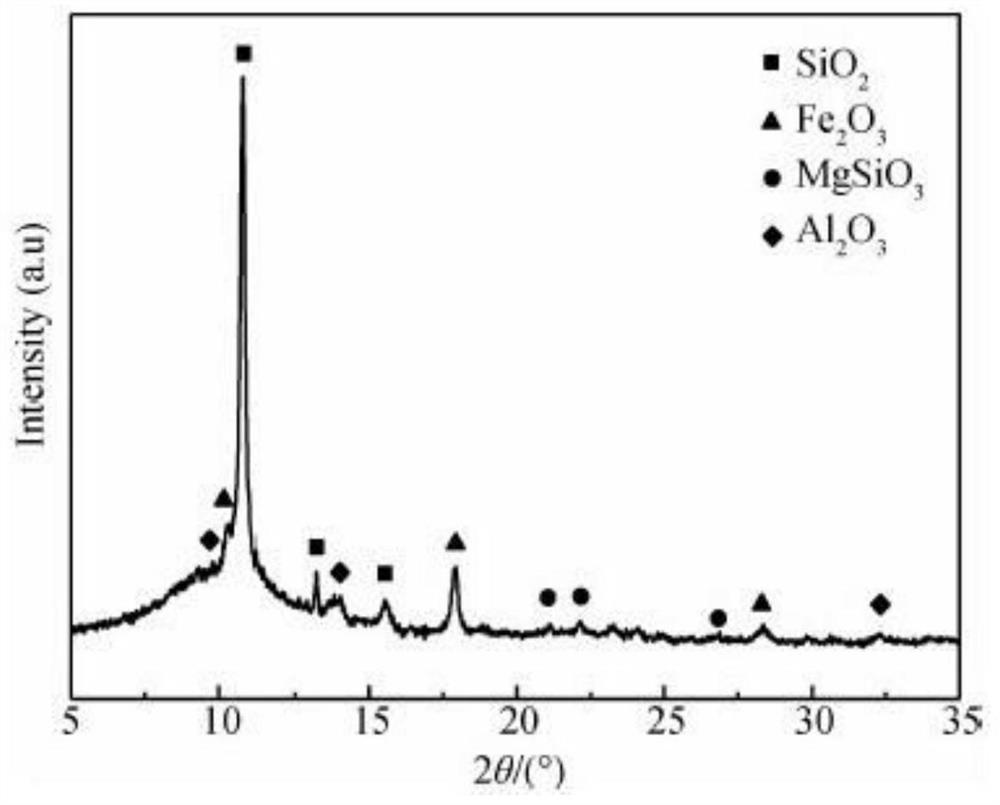

[0047] The preparation method of the rare earth modified diatomite comprises the following steps:

[0048] (1) Heat the diatomaceous earth to 400°C under vacuum, then heat-preserve it for 1-1.5 hours, then take it out, and cool it down naturally;

[0049] The vacuum degree is 0.02MPa;

[0050] The particle size of the diatomite is 30 μm;

[0051] (2) Evenly disperse the heat-treated diatomite into the acidic solution, stir at a speed of 500r / min for 30min, then adjust the pH of the solution to 9.5, continue stirring for 1 hour, and then let it stand for 1 hour to obtain diatom Soil dispersion;

[0052] Described acidic solution is citric acid solution;

[0053] Described citric acid solution mass fraction is 5%;

[0054] The mixing mass ratio of diatomaceous earth and citric acid solution is 300g:800mL;

[0055] The pH of the adjustment solution is adjusted by sodium hydroxide solution;

[0056] (3) Add calcium chloride of 1.5% by mass to the diatomite dispersion obtaine...

Embodiment 1

[0074] A phosphorus-free composite water treatment agent, which is obtained by uniformly stirring and reacting tetradecyl monoester sulfosuccinate, acrylic acid copolymer, sodium tartrate, rare earth modified diatomite, and water in a water bath for heat preservation; the stirring The reaction is subjected to ultrasonic treatment; the preparation method of the rare earth modified diatomite includes the following steps: (1) heating the diatomite to 400° C. under vacuum, and then performing heat preservation treatment for 1 hour, then taking it out, and cooling naturally; The vacuum degree is 0.02MPa; the diatomite particle size is 30 μm; (2) uniformly disperse the heat-treated diatomite into the acidic solution, stir at a speed of 500r / min for 30min, and then adjust the pH of the solution to 9.5, Continue to stir for 1 hour, and then stand still for 1 hour to obtain a diatomite dispersion; the acidic solution is a citric acid solution; the mass fraction of the citric acid soluti...

Embodiment 2

[0076] A phosphorus-free composite water treatment agent, which is obtained by uniformly stirring and reacting tetradecyl monoester sulfosuccinate, acrylic acid copolymer, sodium tartrate, rare earth modified diatomite, and water in a water bath for heat preservation; the rare earth The preparation method of the modified diatomite comprises the following steps: (1) heating the diatomite to 400° C. under vacuum, and then performing heat preservation treatment for 1.5 hours, then taking it out, and cooling naturally; the vacuum degree is 0.02 MPa; The diatomite particle size is 30 μm; (2) uniformly disperse the heat-treated diatomite into the acidic solution, stir at a speed of 500r / min for 30min, then adjust the pH of the solution to 9.5, continue stirring for 1 hour, and then Stand still for 1 hour to obtain a diatomite dispersion; the acidic solution is a citric acid solution; the mass fraction of the citric acid solution is 5%; the mixing mass ratio of the diatomite to the ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com