Anaerobic digestion method based on self-sustaining air floatation screening

A technology of anaerobic digestion and air flotation, applied in microorganism-based methods, anaerobic digestion treatment, chemical instruments and methods, etc. The function of anaerobic digestion of oil to produce methane, avoid excessive dosing of materials at one time, and the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

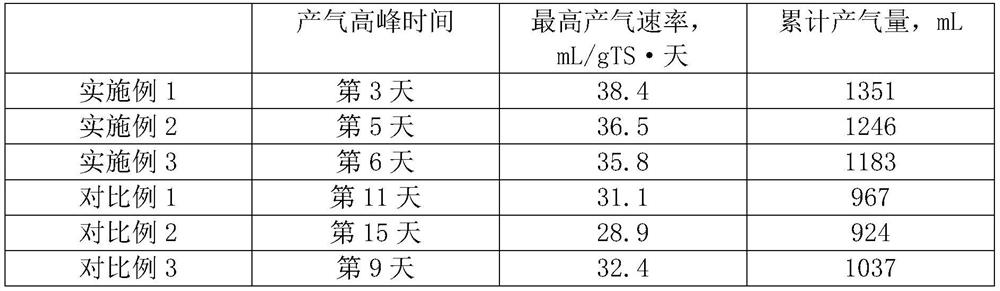

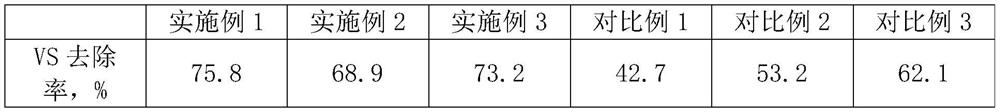

Embodiment 1

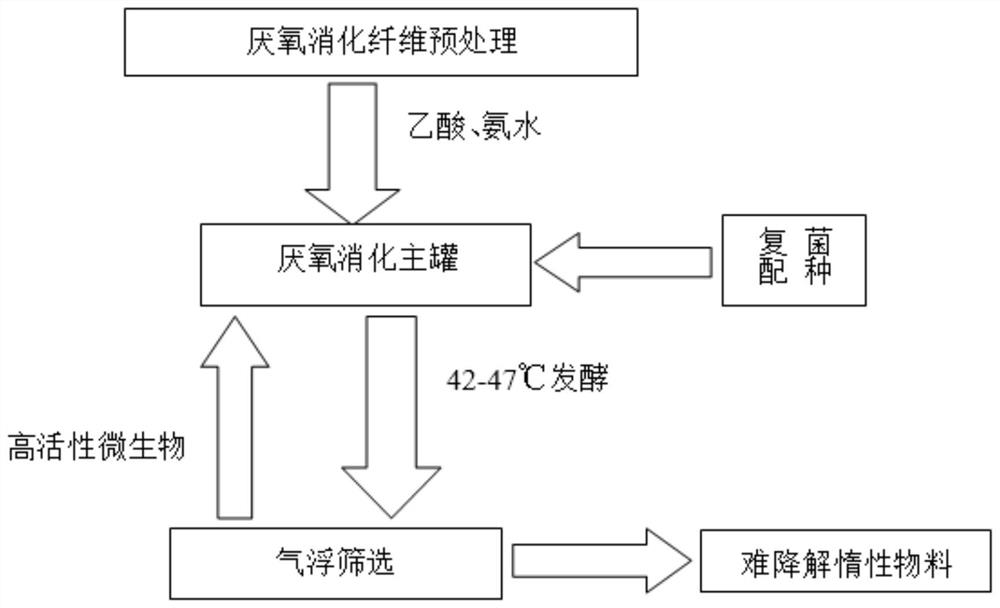

[0035] An anaerobic digestion method based on self-sustained air flotation screening, the process flow chart is as follows figure 1 shown, including the following steps:

[0036] (1) Anaerobic digestion fiber pretreatment: anaerobic digestion fiber is pretreated with acetic acid at 90°C for 2 hours, and the liquid-solid ratio is 12mL / g; after the acetic acid pretreatment is completed, it is pretreated with ammonia water at 95°C for 1.5h, the pretreatment is complete After washing and drying;

[0037] (2) Prepare anaerobic fermentation strains: add anaerobic digestion sludge and fat-degrading bacteria to the basic medium as anaerobic fermentation strains; the anaerobic digestion sludge, fat-degrading bacteria and basic medium The mass ratio is 15:2:100;

[0038] (3) Mixing materials: the anaerobic digested fiber, municipal sludge and anaerobic fermentation bacteria that were pretreated in step (1) are mixed to obtain a mixture; the anaerobic digested fiber, municipal sludge a...

Embodiment 2

[0050] A kind of anaerobic digestion method based on self-sustaining air flotation screening, comprises the following steps:

[0051] (1) Anaerobic digestion fiber pretreatment: anaerobic digestion fiber is pretreated with acetic acid at 90°C for 2 hours, and the liquid-solid ratio is 12mL / g; after the acetic acid pretreatment is completed, it is pretreated with ammonia water at 95°C for 1.5h, the pretreatment is complete After washing and drying;

[0052] (2) Prepare anaerobic fermentation strains: add anaerobic digestion sludge and fat-degrading bacteria to the basic medium as anaerobic fermentation strains; the anaerobic digestion sludge, fat-degrading bacteria and basic medium The mass ratio is 20:1:100;

[0053] (3) Mixing materials: the anaerobic digested fiber, municipal sludge and anaerobic fermentation bacteria that were pretreated in step (1) are mixed to obtain a mixture; the anaerobic digested fiber, municipal sludge and anaerobic fermentation bacteria are mixed ...

Embodiment 3

[0065] A kind of anaerobic digestion method based on self-sustaining air flotation screening, comprises the following steps:

[0066] (1) Anaerobic digestion fiber pretreatment: anaerobic digestion fiber is pretreated with acetic acid at 90°C for 2 hours, and the liquid-solid ratio is 12mL / g; after the acetic acid pretreatment is completed, it is pretreated with ammonia water at 95°C for 1.5h, the pretreatment is complete After washing and drying;

[0067] (2) Prepare anaerobic fermentation strains: add anaerobic digestion sludge and fat-degrading bacteria to the basic medium as anaerobic fermentation strains; the anaerobic digestion sludge, fat-degrading bacteria and basic medium The mass ratio is 10:3:100;

[0068] (3) Mixing materials: the anaerobic digested fiber, municipal sludge and anaerobic fermentation bacteria that were pretreated in step (1) are mixed to obtain a mixture; the anaerobic digested fiber, municipal sludge and anaerobic fermentation bacteria are mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com