Beach buggy belt as well as formula and processing method thereof

A processing method and ATV technology, applied in the field of transmission belts, can solve the problems of belt softening, lateral rigidity, V-belts prone to heating, failure, etc., and achieve the effects of solving dynamic heat generation, solving aging resistance, and enhancing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

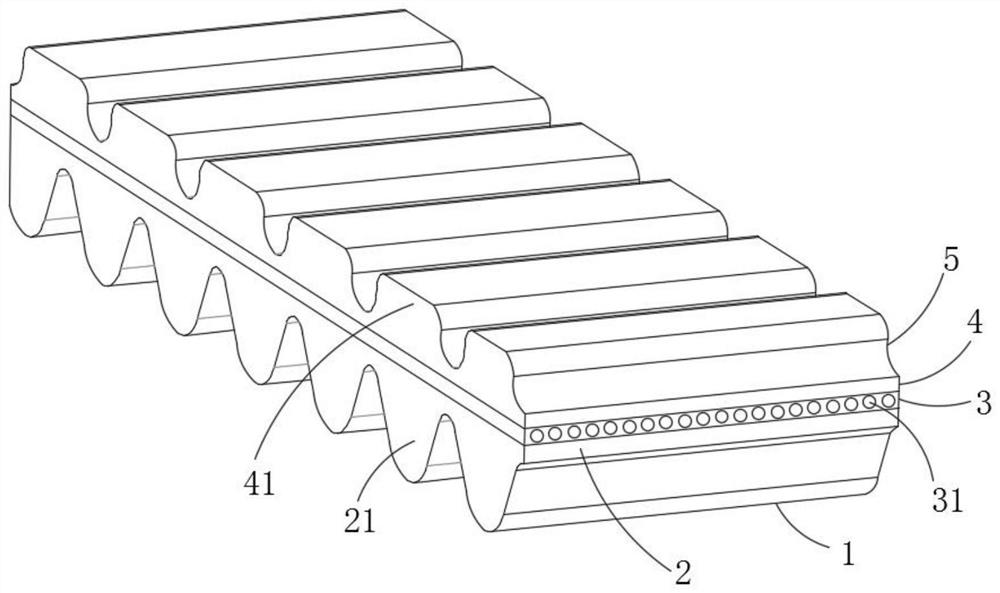

[0031] see figure 1 , the present embodiment provides an ATV belt, which is sequentially provided with a bottom cloth layer 1, a bottom rubber 2, a skeleton layer 3, a top rubber 4 and a top cloth layer 5 from the inside to the outside (from bottom to top in the figure). In the example, the bottom rubber 2 and the top rubber 4 are EPDM rubber, which can be used for a long time at 120-150 °C, which solves the problem of belt aging. The bottom rubber 2 is provided with bottom teeth 21, and the top rubber 4 is provided with top teeth 41. The belt drive has low bending stress, good dynamic bending performance, good heat dissipation performance, and has the advantage of reducing the temperature of the belt itself. . The skeleton layer 3 is provided with an aramid cord 31 along the belt direction, so that no heat shrinkage occurs during transmission and the service life is increased. The bottom rubber 2 is provided with aramid short fibers with a length of 1mm along the direction ...

Embodiment 2

[0033] The present embodiment provides a formula for the above-mentioned ATV belt, characterized in that:

[0034] The primer includes the following components by weight:

[0035] 100 parts of EPDM; 18-23 parts of aramid fiber; 1.5-2.0 parts of zinc stearate; 3-6 parts of zinc oxide; 5-6.5 parts of accelerator ZDMA; 2.0-3 parts of accelerator TAIC; anti-aging agent 4010NA 1-1.5 parts; anti-aging agent RD 1-1.5 parts; white carbon black 8-15 parts; N550 carbon black 35-40 parts; paraffin oil 5-8 parts; anti-scorch agent 0.4-0.6 parts; peroxide curing agent 5- 7 servings;

[0036] Please refer to Table 1 and Table 2 below, the primer adopts the following two groups of formulas in different parts by weight:

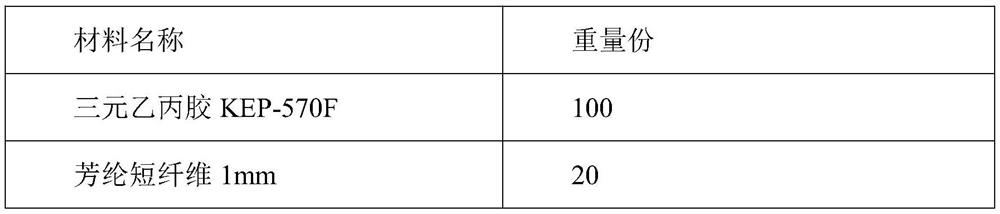

[0037] Table 1: Parts by weight and properties of formula 1 of primer

[0038]

[0039]

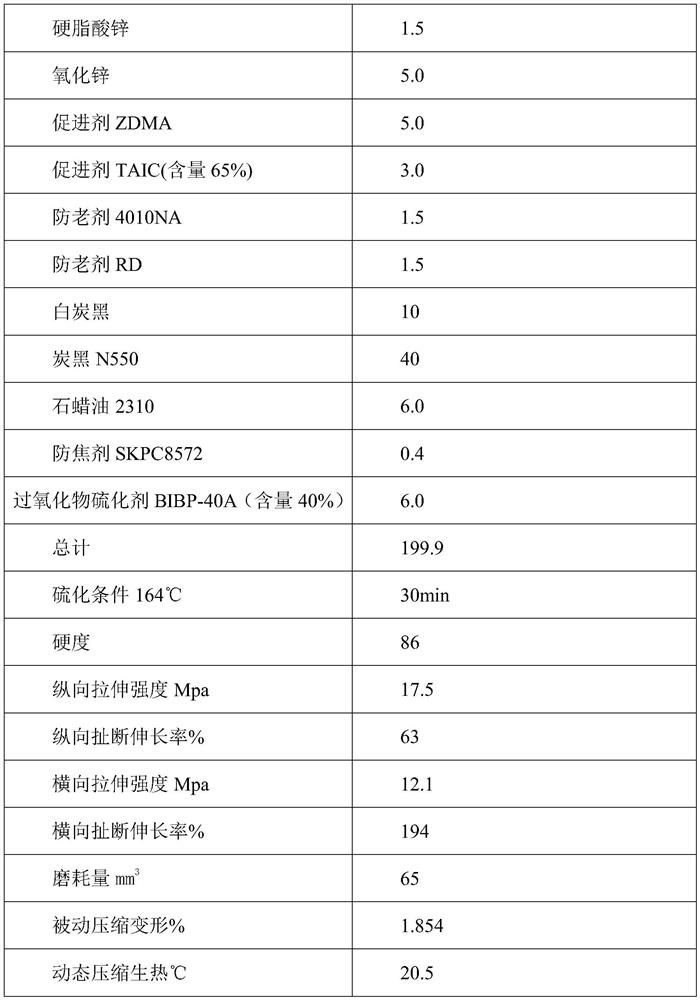

[0040] Table 2: Parts by weight and properties of formulation 2 of primer

[0041]

[0042]

[0043] Described top glue comprises the following components by weight:

...

Embodiment 3

[0058] The present embodiment provides a method for processing an ATV belt, including rubber mixing, sheeting and splicing, wherein the rubber mixing includes one-stage mixing and two-stage mixing;

[0059] A blend:

[0060] The temperature of the internal mixer is less than 90 °C, and the ethylene-propylene diene rubber is added for 30 seconds; then anti-aging agent, accelerator, zinc oxide, zinc stearate and aramid fiber are added (during the top rubber mixing, basket cotton is also added. powder) for 90 seconds; add 2 / 3 carbon black for refining (add calcium carbonate when the top rubber is mixed) for 60 seconds; add 1 / 3 carbon black and paraffin oil for 60 seconds; lift the top bolt for cleaning; continue mixing 90 seconds, the temperature is below 160 ℃, and the material is discharged; then the sheet is cooled on the open mill, and the temperature of the unloading sheet is controlled at 110-120 ℃;

[0061] Two-stage mixing:

[0062] When the temperature of the internal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| wear volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com