Flame-retardant rubber tube and preparation method thereof

A flame-retardant rubber and rubber technology, which is applied in the field of gas mask polymer materials, can solve the problems of poor flame retardancy and aging resistance of rubber airway tubes, and achieve the effects of good flame retardancy, good aging resistance and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

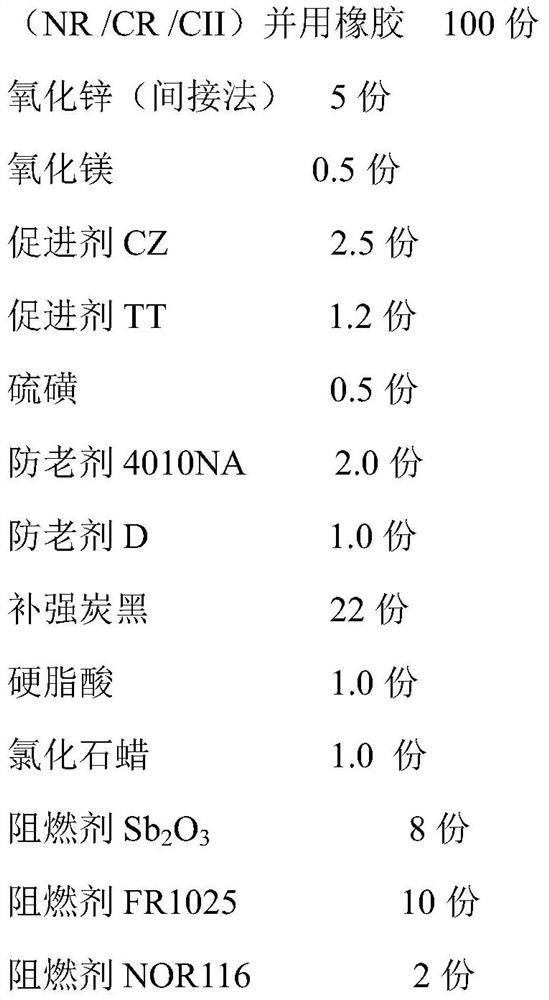

[0026] A flame retardant rubber tube is prepared from the following raw materials in proportions by weight:

[0027]

[0028] A preparation method of a flame retardant rubber tube, comprising the following steps:

[0029] (1), take by weighing (NR / CR / CII=7:2:1) and use rubber, zinc oxide, magnesium oxide, accelerator, sulfur, antioxidant, reinforcing carbon black, hard Fatty acid, chlorinated paraffin, flame retardant;

[0030] (2) After plasticizing NR, CR and CII on the rubber mixing machine first, then blending, then adding zinc oxide, stearic acid, reinforcing carbon black, and anti-aging agent for mixing, and then adding chlorinated paraffin, Flame retardant, the temperature is controlled at 40 ℃ ~ 55 ℃, and finally the accelerator and the vulcanizing agent are added and mixed to obtain the flame retardant and aging resistant adhesive.

[0031] (3) After processing the rubber material that meets the technical indicators, and then extruding and vulcanizing, the corres...

Embodiment 2

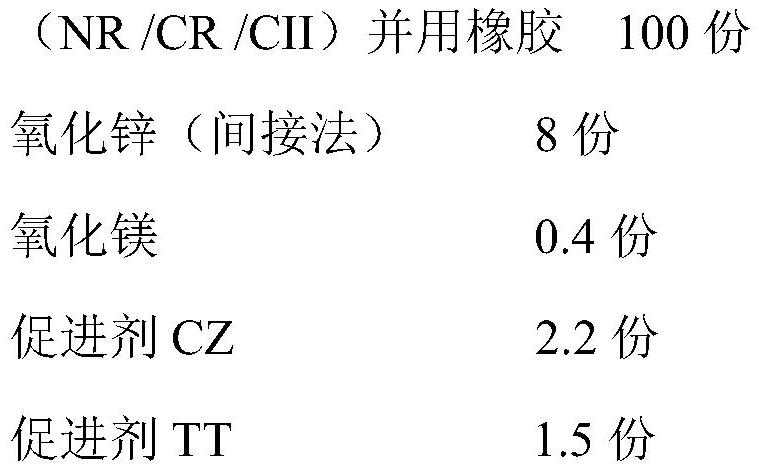

[0033] A flame retardant rubber tube is prepared from the following raw materials in proportions by weight:

[0034]

[0035] A preparation method of a flame retardant rubber tube, comprising the following steps:

[0036] (1), take by weighing (NR / CR / CII=7:2.5:0.5) and use rubber, zinc oxide, magnesium oxide, accelerator, sulfur, antioxidant, reinforcing carbon black, hard Fatty acid, chlorinated paraffin, flame retardant;

[0037] (2) After plasticizing NR, CR and CII on the rubber mixing machine first, then blending, then adding zinc oxide, stearic acid, reinforcing carbon black, and anti-aging agent for mixing, and then adding chlorinated paraffin, Flame retardant, the temperature is controlled at 40 ℃ ~ 55 ℃, and finally the accelerator and the vulcanizing agent are added and mixed to obtain the flame retardant and aging resistant adhesive.

[0038] (3) After processing the rubber material that meets the technical indicators, and then extruding and vulcanizing, the co...

Embodiment 3

[0040] A flame retardant rubber tube is prepared from the following raw materials in proportions by weight:

[0041]

[0042]

[0043] A preparation method of a flame retardant rubber tube, comprising the following steps:

[0044] (1), take by weighing (NR / CR / CII=7:2:1) and use rubber, zinc oxide, magnesium oxide, accelerator, sulfur, antioxidant, reinforcing carbon black, hard Fatty acid, chlorinated paraffin, flame retardant;

[0045] (2) After plasticizing NR, CR and CII on the rubber mixing machine first, then blending, then adding zinc oxide, stearic acid, reinforcing carbon black, and anti-aging agent for mixing, and then adding chlorinated paraffin, Flame retardant, the temperature is controlled at 40°C to 55°C, and finally, an accelerator and a vulcanizing agent are added and mixed to obtain a flame-retardant and aging-resistant adhesive.

[0046] (3) After processing the rubber material that meets the technical indicators, and then extruding and vulcanizing, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com