Cleaning and disinfecting equipment for surgical medical instruments

A technology for cleaning and disinfection of medical equipment, applied in disinfection, sanitary equipment for toilets, medical science and other directions, can solve problems such as low cleaning efficiency, achieve high cleaning and disinfection efficiency, and improve heat utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

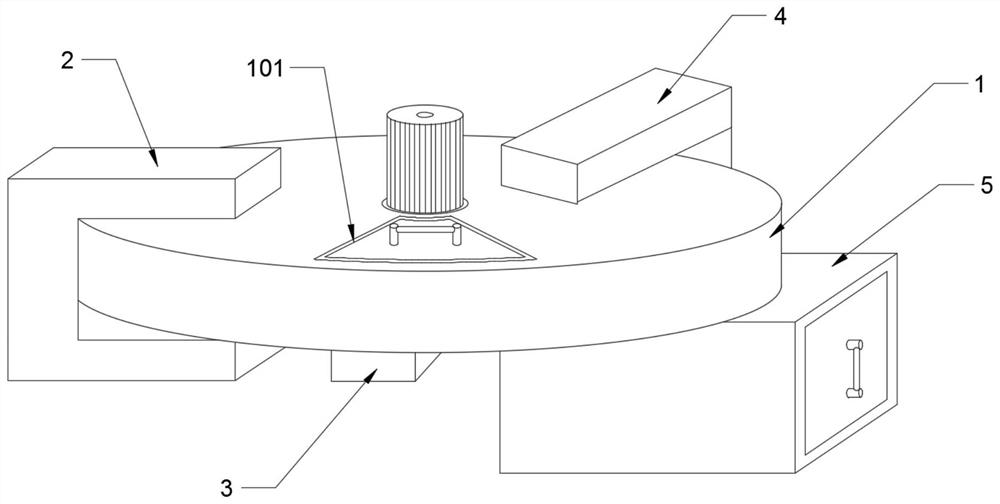

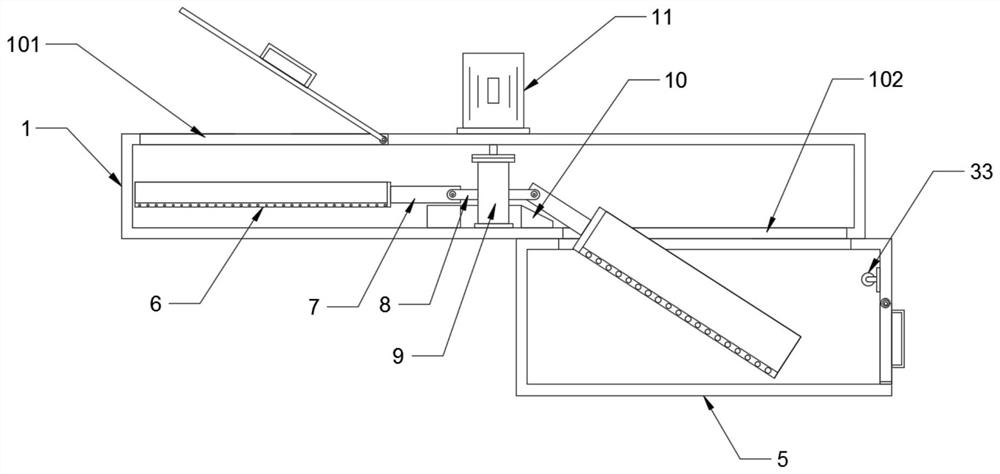

[0025] See Figure 1-4 In an embodiment of the present invention, a surgical and medical instrument cleaning and disinfection equipment includes an equipment body; the equipment body includes a cylinder 1, and the cylinder 1 is a flat hollow cylinder, which is arranged in a clockwise direction along the cylinder 1. There are a high-temperature sterilization mechanism 2, a cleaning mechanism 3, a drying mechanism 4, and a discharge box 5; the upper end of the cylinder 1 is provided with a discharge port 101, the lower end of the cylinder 1 is provided with a discharge port 102, and the discharge port 101 is nested The cover plate hinged to the cylinder body 1 is opened, and the medical device is put into the cylinder body 1 by opening the hinged cover plate.

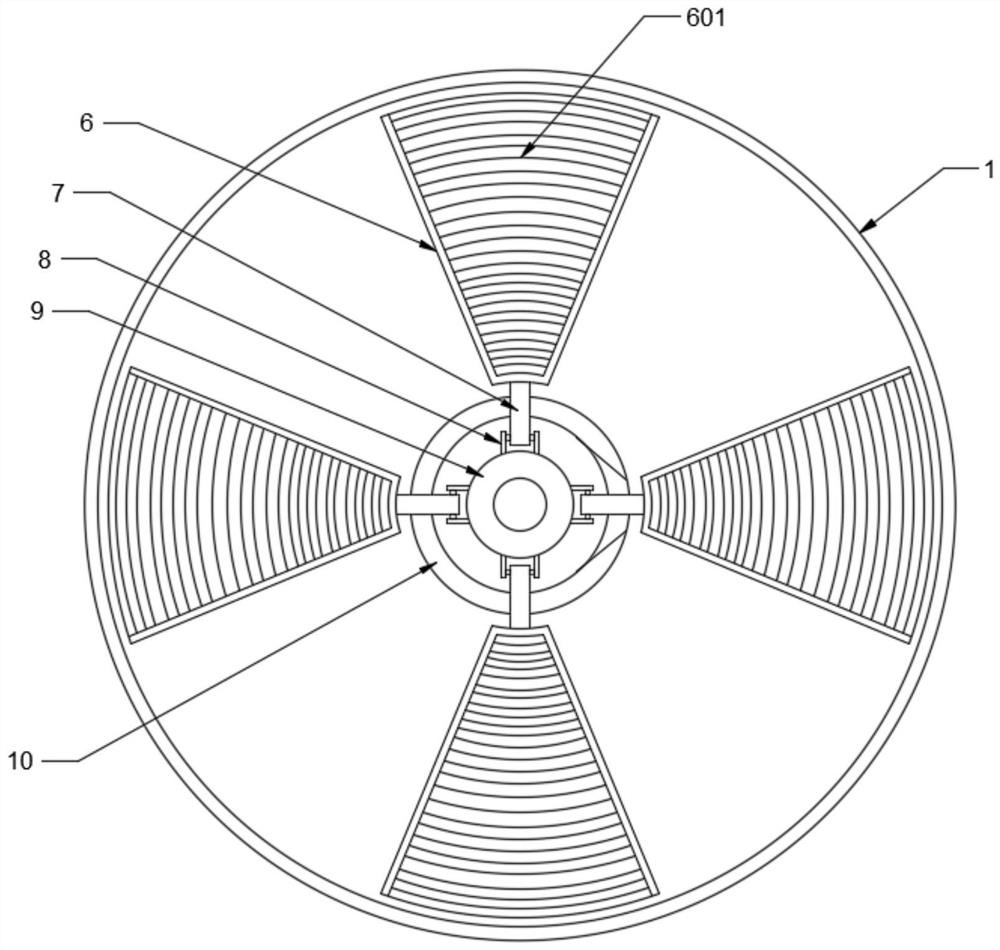

[0026] The cylinder 1 is provided with an instrument transfer mechanism. The instrument transfer mechanism includes a carrying tray 6 nested in the cylinder 1 and distributed in a circle. The carrying tray 6 has a fan-shaped ...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that in order to make full use of heat, the second collection cover 30 is connected to the inner cavity of the steam generating tank 15 through a connecting pipe 32, and an exhaust fan 31 is provided on the connecting pipe 32. 31 Forcefully input the moisture-containing hot gas into the steam generating tank 15. The connecting pipe 32 and the steam generating tank 15 are provided with a one-way valve to prevent the hot gas from returning, and the moisture-containing hot gas is passed into the steam generating tank 15 to accelerate the steam. The production of electric energy saves the electric energy of the heating device 16 and improves the heat utilization efficiency.

[0032] In order to prevent the medical equipment from breeding bacteria again after cleaning, the discharge box 5 is provided with an ultraviolet lamp 33 to prevent the medical equipment from breeding bacteria in the storage type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com