Feed with threonine mother liquor as raw material and preparation method of feed

A technology of threonine mother liquor and feed, which is applied in the field of reuse of threonine mother liquor, can solve the problems of high material viscosity and inability to industrialize large-scale continuous production, and achieve the effect of good fluidity and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Specifically, the preparation method of the feed of the present invention comprises the following steps:

[0036] (1) Concentration: The threonine fermentation broth is filtered through a ceramic membrane to remove bacteria and threonine crystallization, and the mother liquor is evaporated and concentrated by using a three-effect evaporator. Due to the high sugar content of the threonine mother liquor leads to high viscosity, the setting conditions of the three-effect evaporator are: 70-90°C for the first effect, 60-70°C for the second effect, and 50-60°C for the third effect. The dry water content of the concentrated threonine mother liquor is controlled between 50% and 70%.

[0037] (2) Ingredients: corn cob powder, rice husk powder, peanut shell powder, straw powder, starch, maltodextrin, calcium carbonate, silicon dioxide, calcium oxide, calcium hydroxide, sodium hydroxide, magnesium hydroxide One or more (ingredients need to be less than 20 mesh) and the concentra...

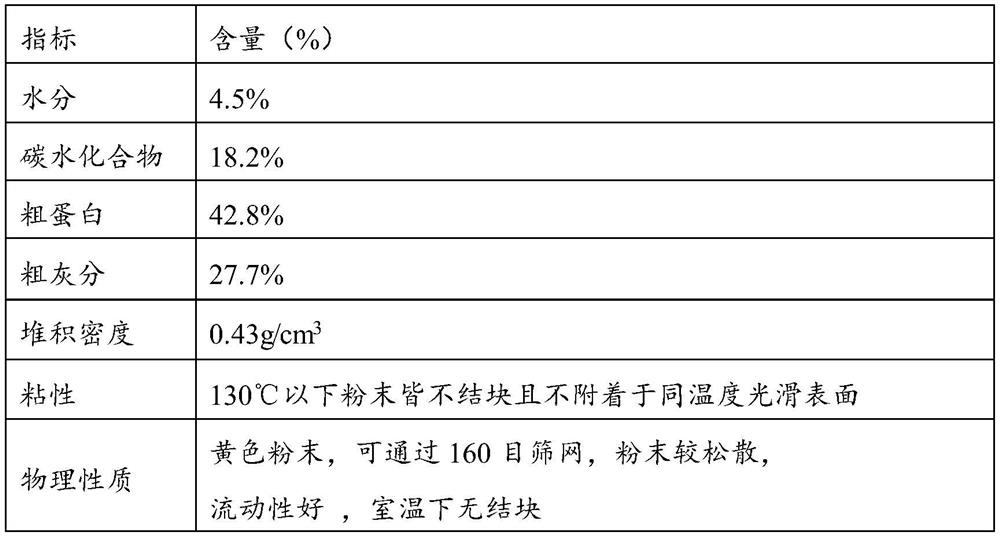

Embodiment 1

[0041] The method for producing energy protein feed by utilizing the threonine mother liquor comprises the following steps: (1) evaporating and concentrating the threonine mother liquor through a three-effect evaporator, and the specific parameters are that the first-effect evaporation temperature is controlled at 82° C., and the second-effect evaporation temperature is controlled at 82° C. 69°C, the three-effect evaporation temperature is controlled at 58°C, concentrated until the dry water content of the threonine mother liquor is 57.2%; (2) Mix the silica and the concentrated threonine mother liquor at a mass volume ratio of 12:100 evenly , and continue to stir to make a suspension; (3) send the prepared feed liquid to the nozzle of the spray dryer at a rate of 1L / h through a peristaltic pump, and maintain the nozzle air pressure at 0.4MPa, 40m 3 / h inlet air temperature, 130°C inlet air temperature, 85°C outlet air temperature, the dried powder is recovered by cyclone. Dur...

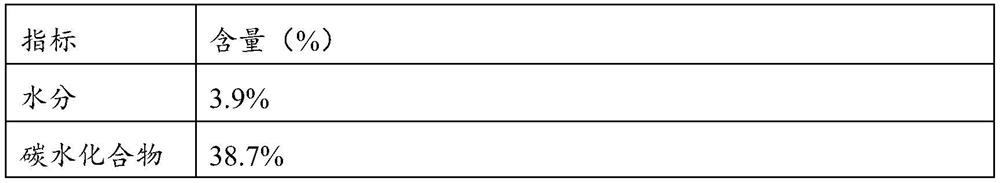

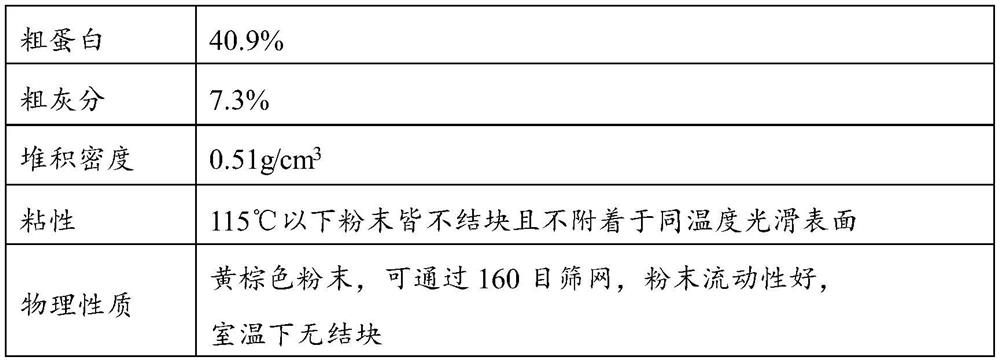

Embodiment 2

[0045] The method for producing energy protein feed by utilizing the threonine mother liquor comprises the following steps: (1) evaporating and concentrating the threonine mother liquor through a three-effect evaporator, and the specific parameters are that the first-effect evaporation temperature is controlled at 80° C., and the second-effect evaporation temperature is controlled at 80° C. 69°C, the three-effect evaporation temperature is controlled at 60°C, concentrated until the dry water content of the threonine mother liquor is 58.8%; (2) mix the starch and the concentrated threonine mother liquor at a mass volume ratio of 20:100, and Continue to stir to make a suspension; (3) Send the prepared feed liquid to the nozzle of the spray dryer at a rate of 1L / h through a peristaltic pump, and maintain the nozzle air pressure at 0.4MPa, 35m 3 / h inlet air temperature, 110°C inlet air temperature, 65°C outlet air temperature, the dried powder is recovered by cyclone. During the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com