Attenuation Devices for Power Electronics Applications

A technology of attenuation device and power electronics, applied in circuit devices, output power conversion devices, measurement devices, etc., can solve the problems of component wear and failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The proposed attenuation device for power electronics applications is advantageously used in shaft drives. It is advantageously used in vehicles that are at least partially electrically driven or fully electrically driven.

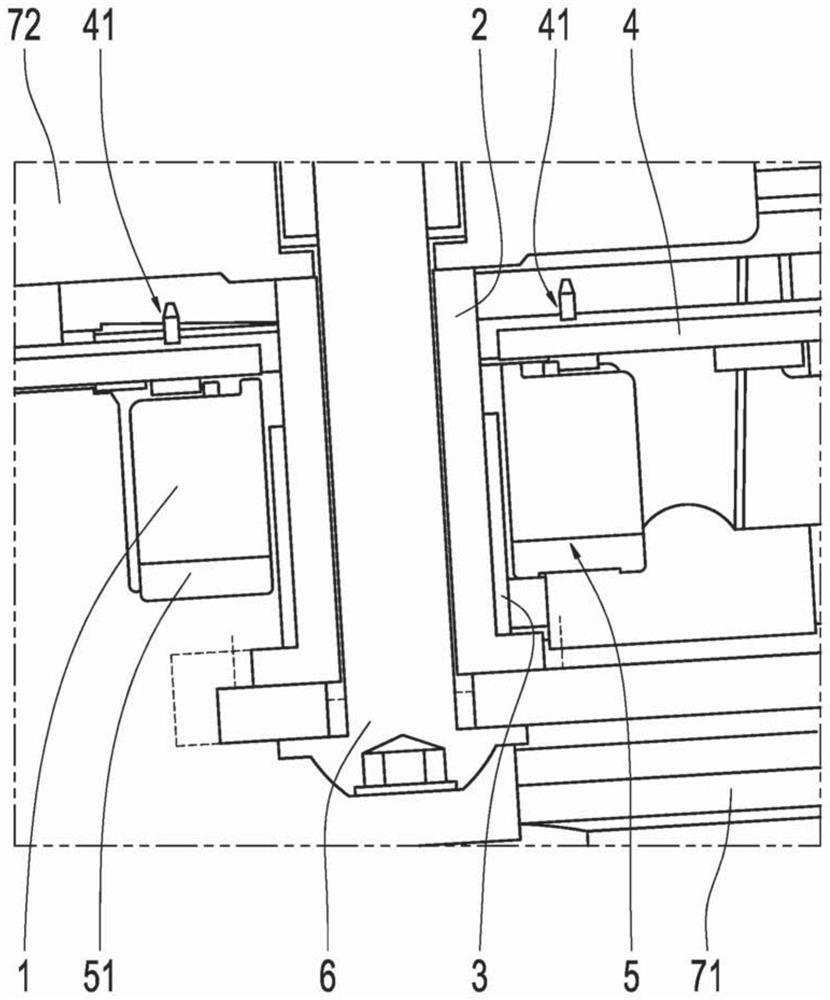

[0021] The object of the invention is to reduce or even avoid vibration loads between the current sensors, more precisely between the current sensor housing 1 surrounding the current sensor or in which the current sensor is arranged, and the electrical contact pin 2 . Another object is to achieve a low load on the connection point 41 between the current sensor and the circuit board 4 , which connection point is usually designed as a soldering point, due to vibration excitation. The probability of component failure is thus also reduced.

[0022] In an application in the field of power electronics for shaft drives described in the form of an exemplary embodiment below, the current sensor conducts a low voltage, and is therefore an LV current sensor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com