A hybrid transmission case clutch oil circuit structure

A technology for clutches and transmissions, which is applied to clutches, hybrid vehicles, motor vehicles, etc., can solve the problems of increasing the outer contour size of the transmission, occupying the outer space of the transmission, and being unfavorable for miniaturization, etc., so as to reduce the outer contour size and simplify Assembly process, effect of reducing the risk of oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

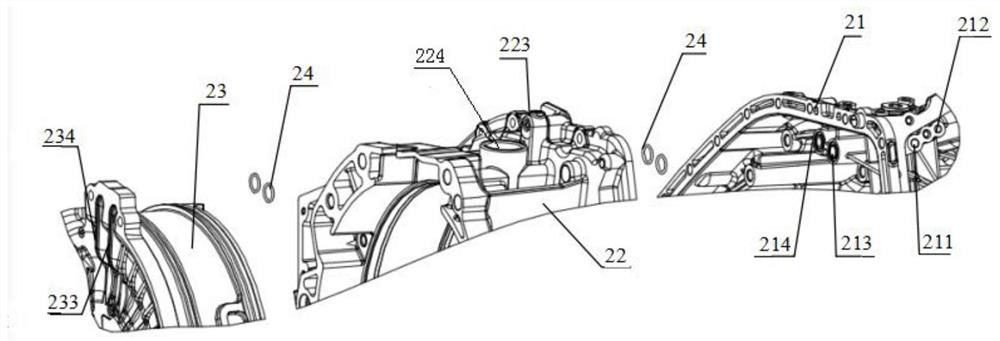

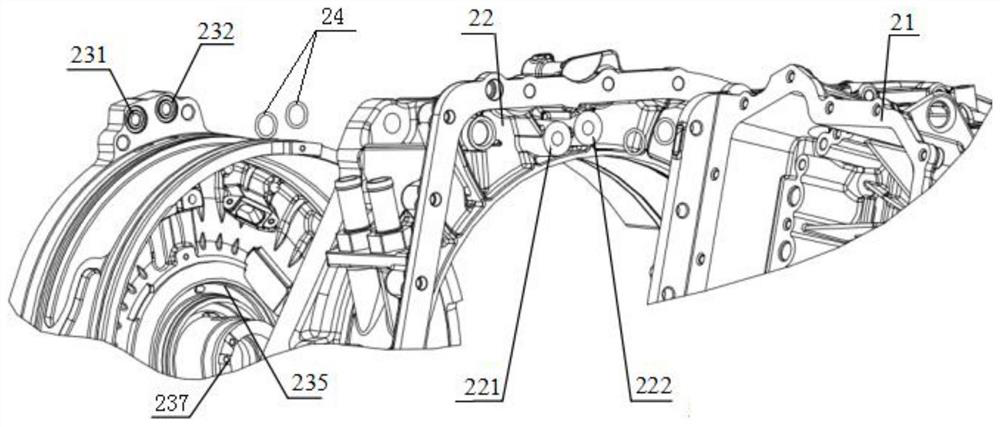

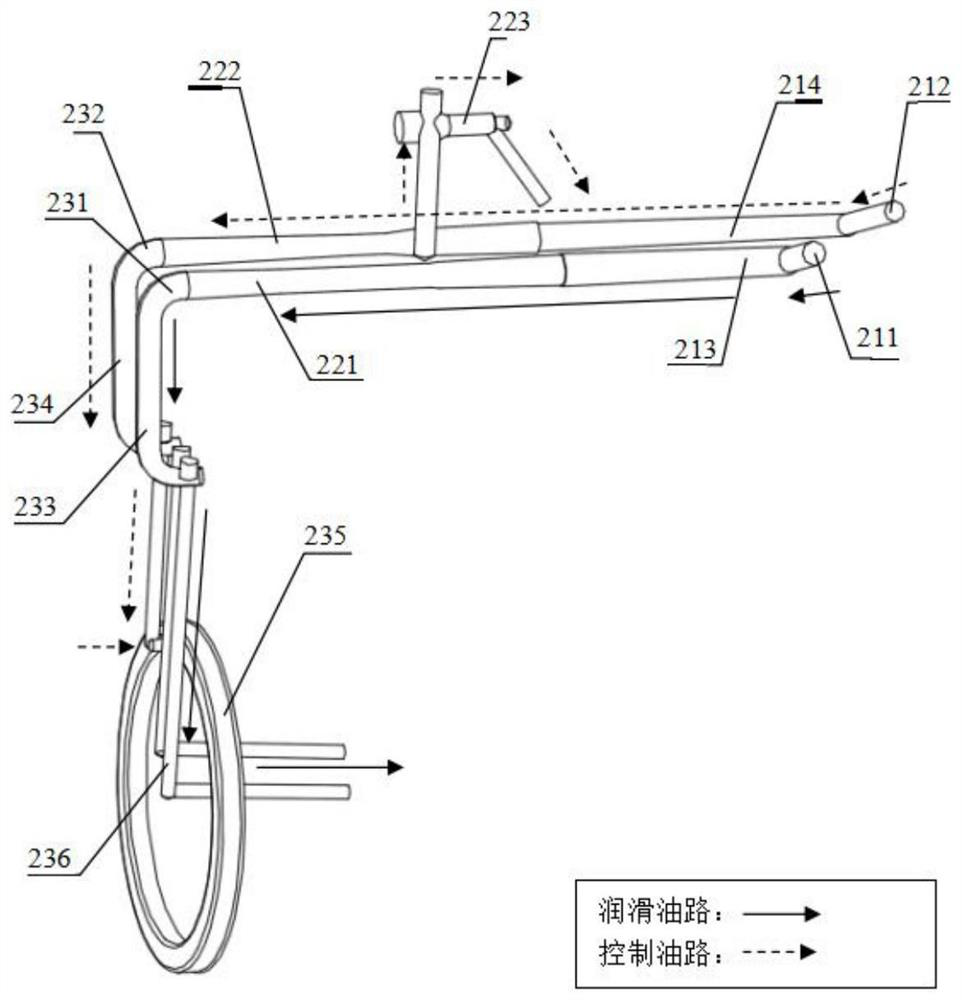

[0025] see Figure 1 to Figure 4 As shown, this embodiment discloses a hybrid transmission case clutch oil circuit structure, including a left case 21, a right case 22 and a P2 housing 23; the left case 21 is provided with a left case clutch lubricating oil inside the housing 213 and the left case clutch control oil passage 214; the right case housing is provided with the right case clutch lubricating oil passage 221 and the right case clutch control oil passage 222; the P2 case 23 is provided with the P2 case clutch control oil passage 234 and P2 shell clutch lubricating oil passages; the oil inlet 211 of the left case clutch lubricating oil passage is used to communicate with the lubricating oil outlet of the hydraulic module 25, and the oil outlet of the left casing clutch lubricating oil passage 213 is connected to the right case. The oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com