Low-inertia and high-heat-power friction pair for clutch brake

A clutch and brake technology, applied in the combination of coupling and brake, clutch and brake type, etc., can solve the problems of clutch-brake difficult to withstand combination-separation, low inertia, high thermal power, wear, etc., and achieve easy disassembly, replacement and maintenance. , the effect of reducing the moment of inertia and efficient thermal load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

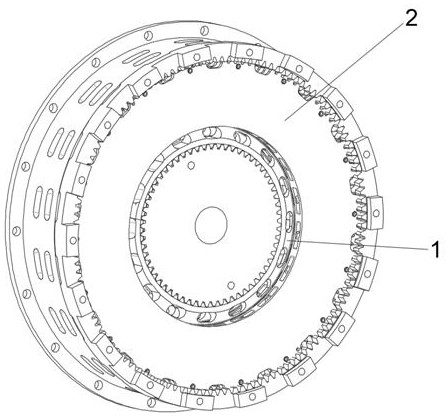

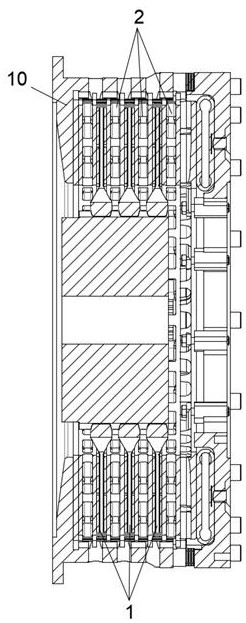

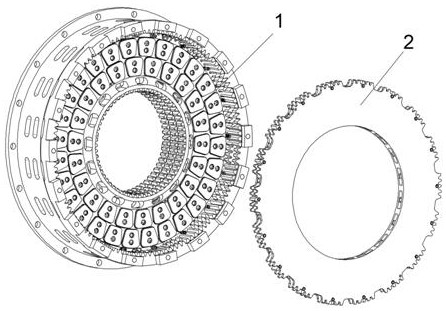

[0023] Such as Figure 1-5 As shown, a friction pair for a clutch brake with low inertia and high thermal power includes a friction disc 1 and an intermediate toothed disc 2. The friction disc 1 and the intermediate toothed disc 2 are arranged alternately in the back plate 10 of the clutch brake. The friction disc 1 includes The inner disc 4, the outer disc 5 and the wedge-shaped friction blocks 6, the inner disc 4 and the outer disc 5 are designed in one piece, and the inner disc 4 is fixed with double rows of multiple wedge-shaped friction blocks 6 on both sides of the surface, each adjacent two wedge-shaped friction blocks There are gaps between the friction blocks 4 and radial and tangential cooling ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com