Prism type self-adaptive drum brake adjusting device

An adjusting device and self-adaptive technology, applied in the direction of the slack adjuster, can solve the problems such as the inability to further increase the outward opening distance of the friction plate, increase the cost of use, and have potential safety hazards, and achieve strong controllability of the shape. , The effect of stable structure and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

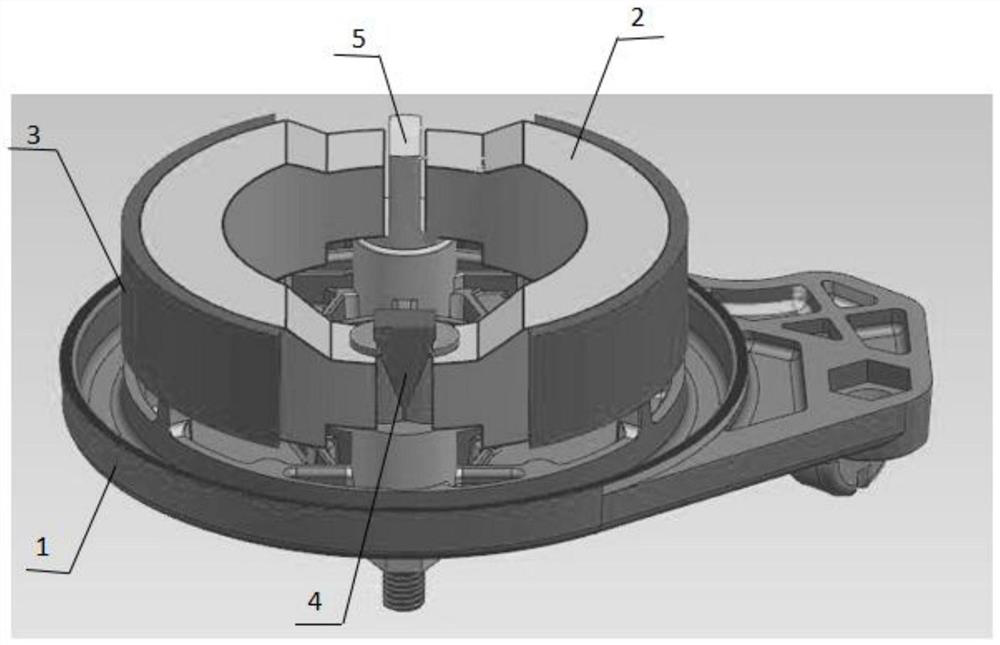

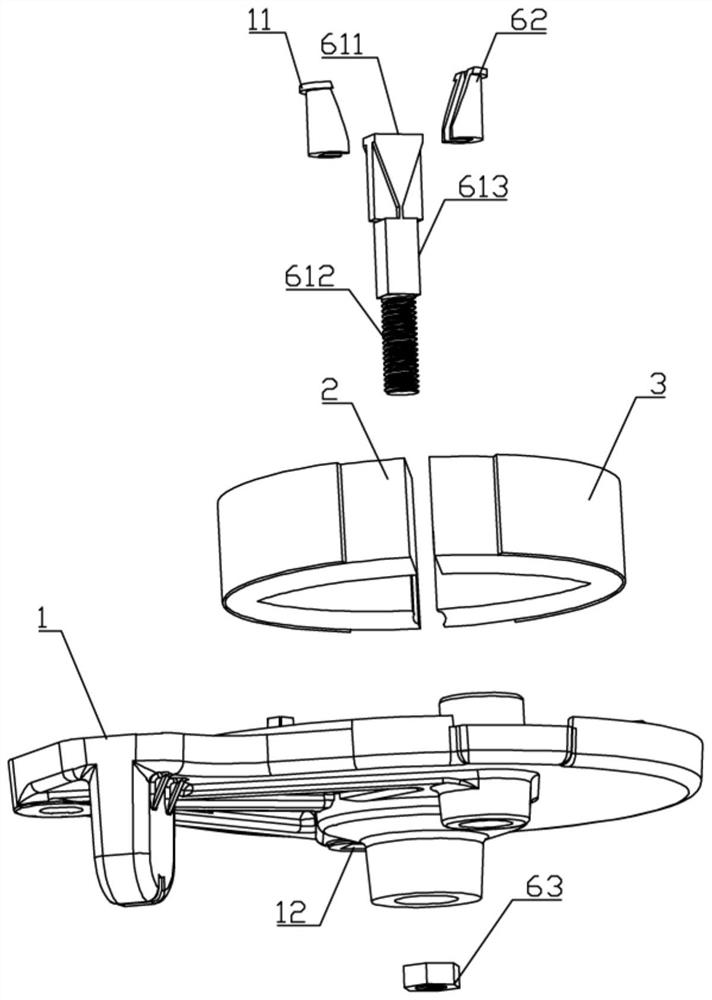

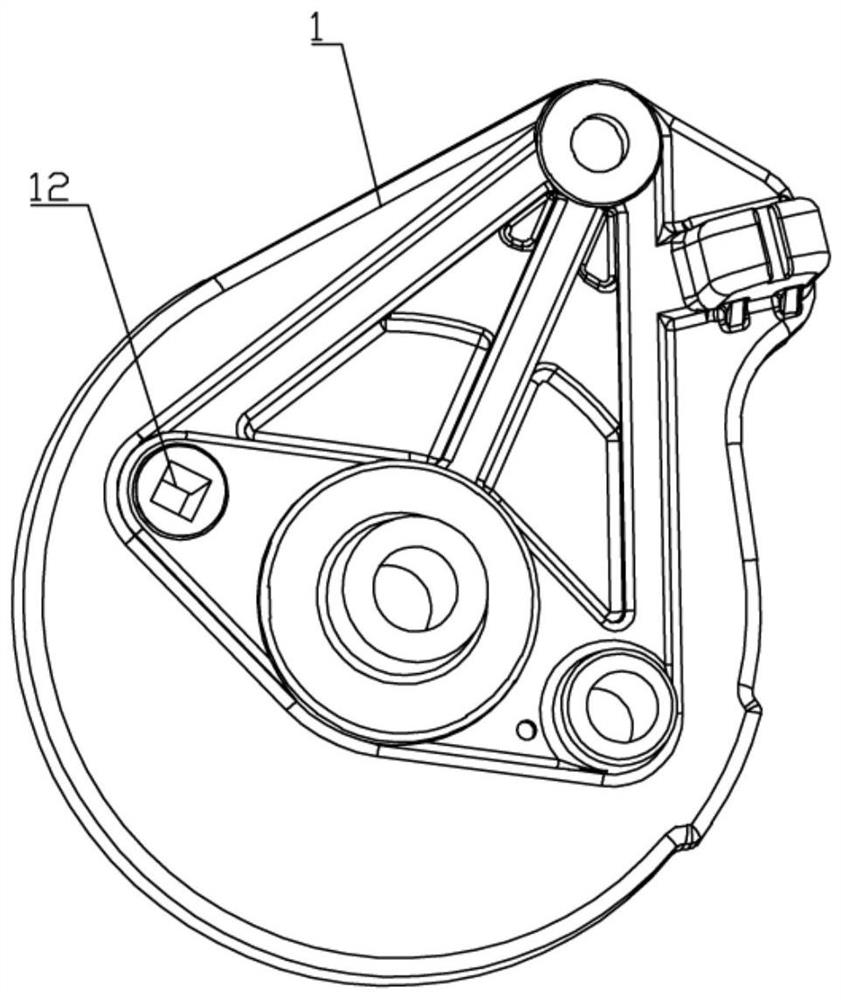

[0032] Such as Figure 1-Figure 7 As shown, a prismatic self-adaptive drum brake adjustment device includes a brake disc 1, two circular-arc block-shaped brake shoes 2 symmetrically arranged on the brake disc 1, and a friction pad arranged on the outer arc surface of the brake shoe 2. Plate 3, the shoe bodies of the two brake shoes 2 are pulled together by the return tension spring 4, and a brake camshaft 5 for controlling the opening and closing degree between the two brake shoes 2 is provided between one set of corresponding ends of the two brake shoes 2 , the other set of corresponding ends is provided with an adjustment component 6, the adjustment component 6 can be adjusted up and down perpendicular to the two brake shoes 2, when the adjustment component 6 is adjusted downward, the adjustment component 6 stretches the two brake shoes 2 to both sides Both sides expand, when the adjustment assembly 6 is adjusted upwards, the two brake shoes 2 are condensed towards the middl...

Embodiment 2

[0039] The difference between the second embodiment and the first embodiment is that both the adjusting rod 61 and the sliding block 62 in the second embodiment have undergone surface treatment, and the specific treatment methods are as follows:

[0040] Immerse the adjusting rod and sliding block in 5% NaOH solution, immerse at 80-85°C for 20-30 minutes to remove the oil stains on the surface, then wash with distilled water and put them in 10% dilute hydrochloric acid solution to wash and remove the surface Residual impurities such as NaOH are finally cleaned with deionized water and dried at a constant temperature of 100°C; the treated adjustment rod and sliding block are immersed in deionized water, and then laser drilling is performed with a nanosecond laser, where the pulse width of the laser is 10ns , the wavelength is 1064nm, the power is 6-10W, the repetition frequency is 20kHz, the height of the adjustment rod and the sliding block from the water surface is 20-28mm, af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com